Quality differences in porcelain tiles can be subtle but critical. Many B2B buyers focus on a tile’s appearance or price and overlook technical quality factors that affect long-term performance. This guide explains how to identify a good porcelain tile and choose a reliable porcelain tile supplier – especially when sourcing from China – by breaking down the key quality indicators in plain language.

1. What Is a "Good" Porcelain Tile? Why Buyers Often Misjudge

Many buyers mistakenly equate a tile’s quality with its looks or cost alone. In reality, a good porcelain tile is a combination of multiple physical properties and manufacturing precision. The tile’s internal qualities (like low water absorption and high strength) and its processing accuracy (consistent size, flatness) determine how well it installs, how long it lasts, and the true cost over time. These factors often only become apparent after installation or years of use, so it pays to evaluate them upfront.

2. Porcelain vs. Ceramic Tile: Quickest Way to Tell

Porcelain tile: Made from finer, denser clay and fired at over 1200°C. It has very low water absorption (≤0.5%) and a hard, stone-like body. The cross-section is fine-grained, and it produces a clear, ringing sound when tapped (a sign of density).

Ceramic tile (non-porcelain): Made from ordinary clay at lower temperatures with higher water absorption (often >6%). The body is more porous and coarse. Tapping it yields a dull thud. These tiles are usually used for walls or low-stress areas due to their higher porosity.

3. Water Absorption: #1 Indicator of Porcelain Quality

Water absorption is the primary indicator of a porcelain tile’s density and vitrification. It directly affects stain resistance, frost durability, and strength. According to ISO 10545-3 (the international standard test), porcelain is defined by water absorption ≤0.5%. In practice, the best China porcelain tile manufacturers can achieve absorption as low as 0.1%, indicating extremely high material purity and firing quality. Lower absorption means the tile won’t soak up moisture or stains easily and can withstand freeze-thaw cycles without cracking.

4. Size Precision and Calibration: Why Consistency Is Critical

Precise tile dimensions are crucial for seamless installation. Even small size deviations can cause uneven grout lines or misaligned joints. The ISO 10545-2 standard specifies allowable tolerances for length, width, thickness, edge straightness, squareness, and flatness. Good factories calibrate tiles so that each piece in a batch is nearly identical (often less than 1 mm size variation). Modern porcelain production yields very consistent sizing, but buyers should verify this to avoid issues when laying the tiles.

5. Flatness, Warping, and Lippage: Hidden Issues in Large Tiles

Warpage standards: Large-format tiles (e.g. 600×1200 mm or bigger) are harder to keep perfectly flat. Standards like ANSI A137.1 set strict limits on how much a tile can bow. Typically, edge warpage must be under ~0.25%–0.35% of the tile’s length (around 3–4 mm on a 1200 mm tile).

Top-tier flatness: Leading manufacturers such as Kito, Monalisa, Kingsun enforce even tighter flatness control – often keeping warping below 1 mm on a 1200 mm tile – far exceeding standard requirements. This level of precision comes from advanced production and quality control.

Why it matters (Lippage): If tiles are not flat, installed floors will have lippage (height differences between adjacent tiles). This is both a tripping hazard and an eyesore. To ensure a safe, smooth surface, the height variation between tiles should be <0.5 mm after installation. That kind of result is only possible if the tiles themselves are very flat from the factory.

6. Surface Durability: PEI Wear Rating and Practical Use

Glazed porcelain tiles have their surface hardness rated by the PEI scale (EN ISO 10545-7 abrasion test). The PEI rating1 runs from Class I (least wear-resistant) to Class V (most durable). Use the PEI class to match tiles to the appropriate environment:

PEI I: For wall use only – not suitable for floors (very light duty).

PEI II: For light traffic residential floors (e.g. home bathrooms or bedrooms with soft footwear).

PEI III: Suitable for all residential floors and light commercial use.

PEI IV: For heavy-use residential and general commercial areas (shops, restaurants, hotel lobbies).

PEI V: For very high-traffic commercial spaces (extreme wear conditions like airports, shopping mall corridors).

Higher PEI tiles have more robust glazes that resist scratches and wear, ensuring the surface design won’t wear off under foot traffic.

7. Break Strength (Modulus of Rupture): Is the Tile Strong Enough?

“Modulus of rupture” (MOR) is the key measure of a tile’s breaking strength. It tells you how much bending or load a tile can withstand before it snaps:

Standard floor tiles: A typical indoor porcelain floor tile (e.g. 600×600×9 mm) should have MOR ≥35 N/mm² (per EN 14411 standard). Premium quality tiles often exceed 50 N/mm², providing extra safety margin for heavy use or commercial traffic.

Thick outdoor pavers: Outdoor porcelain pavers (~20 mm thick) and tiles for driveways or plazas need even higher strength (usually ≥50 N/mm²). They also must be frost-resistant (as tested by ISO 10545-12) to survive freeze-thaw cycles.

Always check the tile’s technical datasheet or test reports for breaking strength to confirm it’s fit for your intended use.

8. Slip Resistance: Choosing the Right Surface for Each Area

DCOF testing:2 Slip resistance is crucial, especially in wet areas. It’s measured by the Dynamic Coefficient of Friction (DCOF). The ANSI A326.3 standard (using the BOT-3000E device) sets benchmarks for tiles in wet conditions.

Recommended values: For dry indoor areas, a DCOF of ≥0.42 is generally acceptable. In wet zones like bathrooms, kitchens, or public restrooms, look for a wet DCOF of ≥0.42 (the minimum for “slip resistant” per ANSI) and preferably around 0.60 for extra safety.

R-rating (ramp test): Europe uses an R9–R13 ramp slip rating. The higher the R-value, the more slip-resistant the tile. For normal indoor wet areas (home bathrooms, kitchens) R10–R11 surfaces are usually sufficient. For outdoor patios, pool decks, or ramps that get water, R11 or R12 tiles are recommended to ensure secure footing.

9. Visual Warning Signs of Low-Quality Tiles

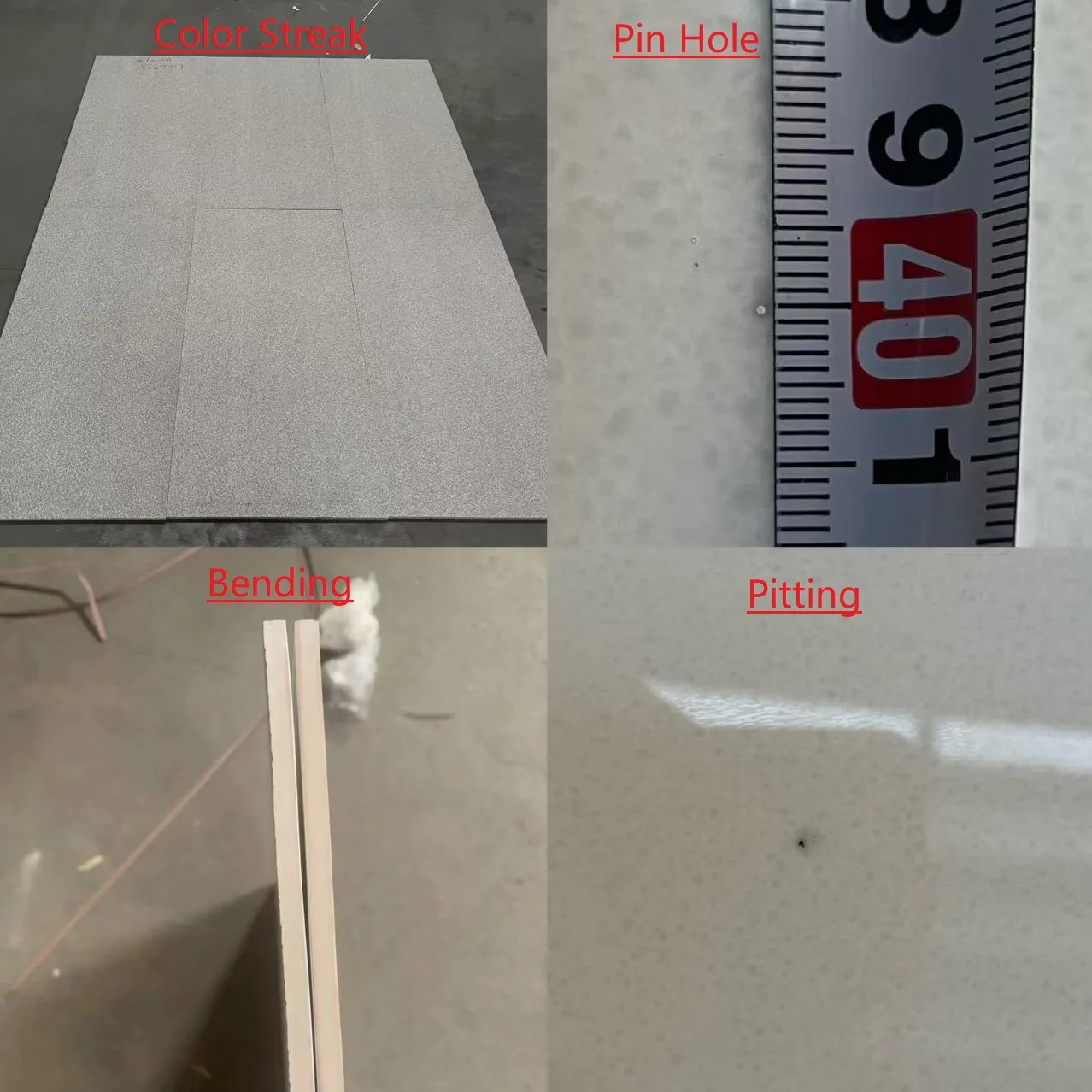

Watch out for these red flags when inspecting porcelain tile samples or shipments:

Color inconsistency: Tiles that are supposed to be the same might show obvious shade or pattern differences within one box or batch. This uneven color tone could signal poor quality control or mixing of batches.

Glaze defects: Look closely for tiny pinholes, bubbles, black specks, missing glaze spots, or hairline cracks on the surface. Such imperfections in the glaze indicate manufacturing issues and can affect appearance and durability (dirt can lodge in pinholes, etc.).

Chipped edges or corners: If you find small chips on tile edges/corners straight out of an unopened box, it suggests the tiles have low strength or were not handled carefully at the factory. Quality tiles, especially from a top supplier, should have intact edges when packaged properly.

Poor labeling/packaging: Check the carton graphics and labels. A reputable manufacturer will clearly print their name, logo, tile model, size, grade, quantity, and a batch number on each box. Fuzzy or missing information may hint at a less trustworthy source.

10. Quick Tests You Can Do Before Buying

Before committing to a large order, perform a few simple tests on samples or at the warehouse to gauge quality:

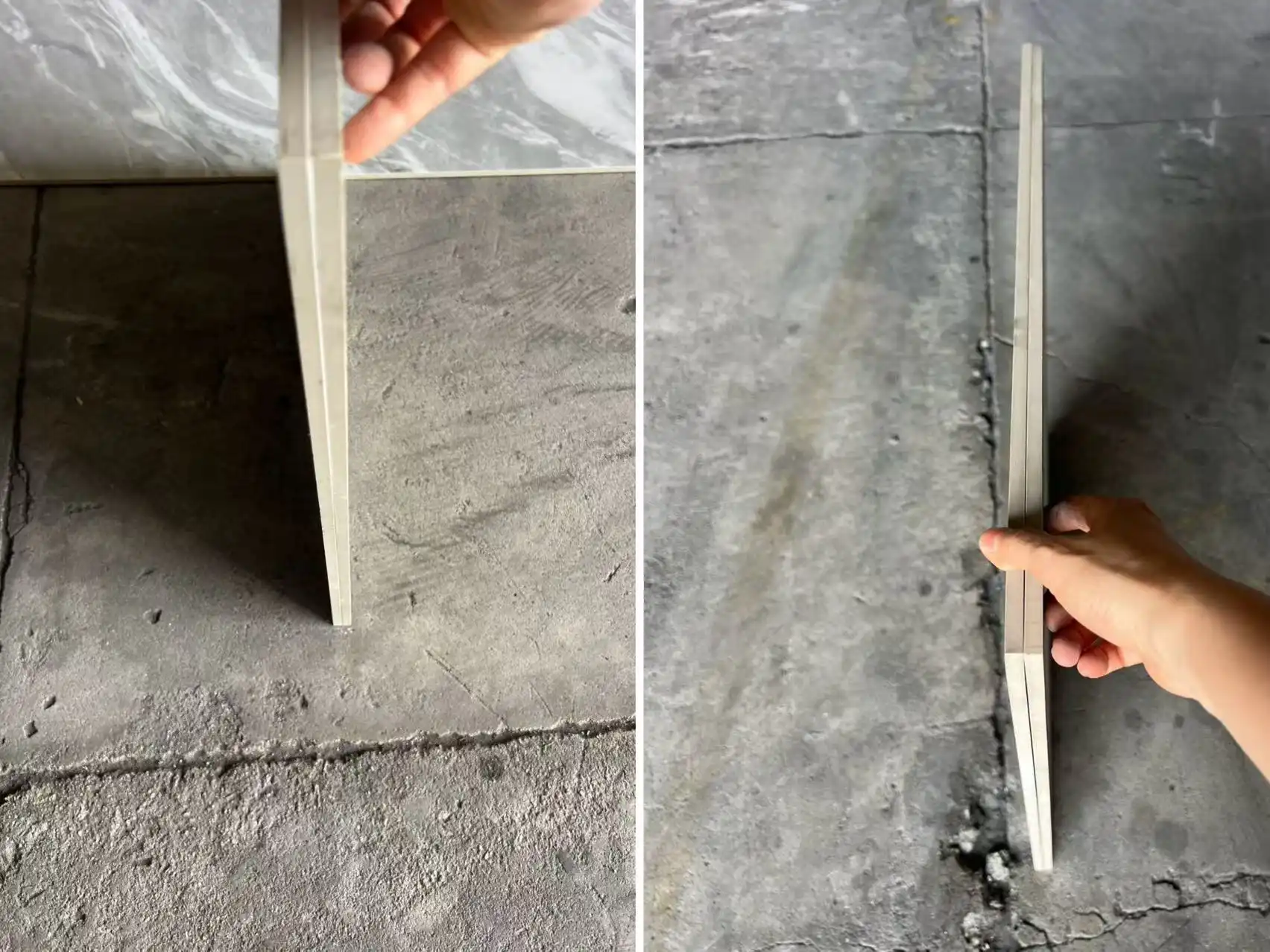

Flatness test: Take two tiles and press their faces together (face-to-face). Hold them together on one side and look at the gap on the opposite side. The smaller and more uniform that gap, the flatter the tiles are.

Size consistency check: Use a tape measure or caliper to measure the diagonal length of multiple tiles from the batch. All pieces should be extremely close in size – any noticeable difference (more than a millimeter) could cause alignment issues when installing.

Sound test: Lift a tile and tap it with a hard object (like a coin or small hammer). A high-quality porcelain tile will emit a clear, ringing “clink” sound, whereas a lower-density tile sounds dull. A ringing sound suggests the tile body is very dense and well vitrified.

Water drop test: Drip a few drops of water on the unglazed backside of the tile. Observe how quickly (or if) the water is absorbed. On a true porcelain tile, the water will barely penetrate even after a few minutes – the drops should sit on the surface or spread very slowly without obvious absorption.

Slip test: Wet the tile’s front surface and then run your hand or a shoe sole over it to feel the traction. This gives a rough idea of its slip resistance. A tile for wet areas should feel grippy rather than slick when wet.

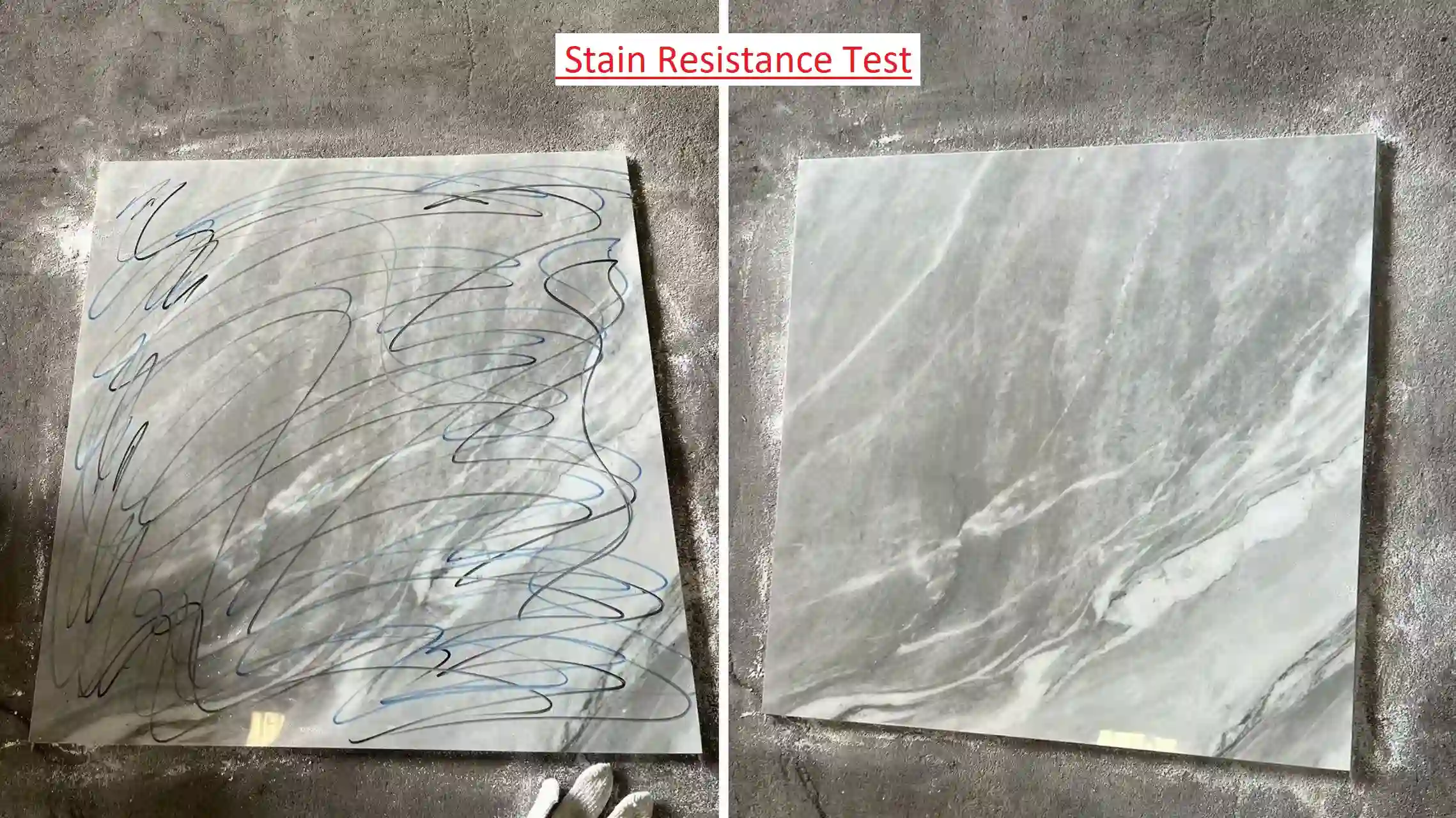

Stain test: Use an oil-based permanent marker to draw a line or X on the tile’s glazed surface. Let it sit for 5–10 minutes, then try wiping it off with a dry cloth or a mild cleaner. A good quality glaze will not absorb the ink and will clean off completely, indicating high stain resistance.

Surface inspection: View the tile under good light at a low angle. This helps reveal any surface irregularities. Check that there are no tiny pinholes or grit in the glaze. Also, if the tile has a printed pattern (like stone or wood look), see if the design is crisp and natural. Avoid tiles where the pattern looks very blurry or repeats too frequently – those are signs of cheaper digital printing.

11. Certifications and Standards: Verify Documents and Avoid Fakes

Quality porcelain tile suppliers should back up their claims with proper certifications and test reports. Here’s what to look for and do:

Request third-party test reports: Insist on recent test reports from internationally recognized labs like SGS, Bureau Veritas, or Intertek. These reports, done according to ISO 10545 standards, will show objective data on water absorption, breaking strength, abrasion resistance, slip resistance, etc. Also acceptable are reports from accredited domestic labs (look for a CNAS or ILAC-MRA logo on the report, indicating the lab is certified).

Necessary certifications: Make sure the supplier provides required certifications for your market. For example, CE certification is mandatory for tiles sold in the EU – ask for the CE certificate and its Declaration of Conformity with EN 14411 test results. In North America, you might look for safety marks like UL. Environmental or health labels like GreenGuard (for low VOC emissions) can also be a plus if needed for green building projects.

Verify details to spot fakes: When you receive a test report or certificate, verify that the product described on it (tile type, model name, size, color, batch number) exactly matches the tiles you are buying – unscrupulous suppliers might pass off a report for a different product. Check that the report is dated recently (within the last year) to reflect current production. If in doubt, you can contact the issuing lab or check their online database to confirm the report number and details.

12. Color Consistency and Batch Control: Why Projects Reject Tiles

One common reason tiles get rejected on job sites is color inconsistency. Even slight shade variation can ruin the look of a tiled surface if mixed tiles are used. Here’s how to manage this:

Understand shade variation: Small fluctuations in raw materials, glaze formulation, or kiln temperature between production runs can lead to noticeable color tone differences between batches of tiles. Reputable factories mitigate this by using computerized color sorting and by keeping each production lot consistent and labeled.

Insist on single-batch supply: Always ensure your order is fulfilled from a single production batch (also called a single “shade lot”). Confirm with the supplier that all boxes will carry the same batch number or shade code. This guarantees that all tiles have the same tone and will look uniform when installed.

Order extra for attic stock: Purchase a surplus of about 5–10% from that same batch to keep as spares. This covers any on-site cutting waste and future repairs. If you run short and reorder later, there’s no guarantee a new batch will match the exact color of the original, so it’s best to have extras from the initial batch.

13. Packaging and Pallets: Overlooked Causes of Breakage and Claims

Proper packaging is vital to get tiles to their destination intact. Poor packaging and palletizing can result in high breakage rates (and insurance claims). A quality-focused supplier will pay attention to the following:

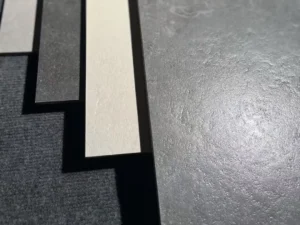

Strong cartons: Tiles should be packed in robust, thick corrugated boxes, ideally with reinforced edges or corner protectors. The boxes should have clear labels with all product details and handling instructions (including “Fragile” or “This Side Up” where appropriate).

Internal protection: Inside the box, there should be padding between tiles – for example, foam sheets or plastic spacers between each piece – to prevent them from chipping each other. Large-format tiles are often packed one per box or with extra foam wrapping to protect them.

Secure palletizing: Cartons must be stacked on sturdy, undamaged pallets that can support the weight. The load should be tightly packed and squared, with a flat board or cardboard sheet on top to protect the upper layer. Everything is then strapped tightly with strong packing bands and wrapped all around with stretch/shrink film to prevent shifting. Oversized or very heavy pallets should have clear markings for forklift handling (to avoid accidents when lifting).

By specifying good packaging in your contract and working with suppliers who follow high packaging standards, you can dramatically reduce transit damage.

14. Common Mistakes to Avoid When Importing Tiles

Even experienced buyers can make mistakes that lead to quality issues or losses. Avoid these common pitfalls:

Relying on lowest price or a pretty sample only: Don’t make a decision based solely on the cheapest quote or a nice-looking sample piece. Ultra-cheap tiles may hide quality problems. Always consider the technical specifications and test results behind the product.

Mixing batches in one order: Never accept tiles from different production batches for the same project (unless they’re intentionally different colors). Mixed batches can mean slight color or size differences that will show up on the floor.

Ignoring packaging requirements: If you don’t specify proper packaging and pallets in the contract, you might receive tiles in subpar packing. That often leads to a high breakage rate during shipping – a false economy that costs you more in the end.

Skipping inspection: For large orders, failing to do a pre-shipment inspection is risky. Always consider hiring a third-party inspection service to check product quality, quantity, and packaging before the tiles ship out. This helps catch issues when they can still be fixed.

Misunderstanding trade terms: Be clear on Incoterms and logistics. For example, if you agree on FOB (Free On Board) terms but don’t nominate a freight forwarder, you might lose control over the shipping and incur unexpected costs or delays. Know who handles what in shipping to avoid surprises.

15. Pro Buyer’s Checklist Before Placing an Order

Before you finalize a tile order, especially from a new porcelain tile supplier, ensure you have all the key information. A professional buyer will ask the supplier for the following:

Detailed product specification sheet – covering all relevant physical and chemical properties (e.g. size, water absorption, strength, surface finish, slip resistance, etc.).

Recent third-party lab test report – results for the specific product (according to ISO 10545 series or equivalent), ideally from a certified lab, to verify the tile meets standards.

Production sample or color swatch – an actual tile from the current production lot, or a finalized sample board, to confirm the appearance and color before mass shipment.

Packaging details – clear description or photos of how the tiles will be packed (box specifications, pieces per box, pallets, protection measures). If possible, get pictures or a video of a prepared pallet.

Batch consistency assurance – a guarantee that all tiles will come from one batch (one shade/caliber), and that this batch number will be noted on the packaging and documentation.

Supplier credentials – copies of the manufacturer’s business license, any industry certifications, and evidence of past export experience or client references. This helps verify the factory’s legitimacy and capability.

Clear contract & warranty terms – a pro-forma invoice or sales contract that spells out product specs, quantities, price, delivery terms, and any warranty or after-sales policy (e.g. how defects or damage claims are handled).

Necessary compliance certificates – e.g. CE certificate and Declaration of Performance for EU projects, or other local certifications required in your market.

Checking off these items will greatly reduce the risk of surprises and ensure you know exactly what you’ll receive.

16. Conclusion: Choosing a Reliable Porcelain Tile Supplier

A reliable supplier is not just a seller of tiles, but a technical partner and problem-solver. Look for manufacturers who are transparent and proactive about quality: they readily provide full test data, discuss production details, guarantee batch consistency, and have a rigorous internal QC system. It’s often worth visiting the factory (or doing a live video audit) to see their production setup, modern equipment, and quality management in action. In short, partner with a supplier who puts quality first.

Ready to source high-quality porcelain tiles? Contact Miller at miller@kingsuntile.com for expert guidance or to discuss your project needs. We’re happy to help you get the best tiles for your business & project.

FAQ

Q1: How can I confirm a tile is true porcelain and not just labeled “porcelain”?

A: Request a water absorption test or report from the supplier. Genuine porcelain has ≤0.5% absorption by definition. You can also do a quick water drop test on the tile’s back – a high-quality porcelain tile will hardly absorb the water (the patch of moisture won’t spread much).

Q2: What water absorption is considered high quality for porcelain tiles?

A: By standards, porcelain is ≤0.5% water absorption. Really high-quality porcelain tiles (as made by leading Chinese manufacturers) can reach ~0.1% or even less. The lower, the better in terms of density and performance.

Q3: Which PEI rating should I choose for home floors vs. commercial projects?

A: For home use, choose at least a PEI III rated tile for floors (this covers normal residential wear). For commercial areas, go with PEI IV for general foot traffic and PEI V for very heavy traffic zones like airports or mall corridors.

Q4: What is a good slip resistance rating for bathroom, kitchen, and outdoor tiles?

A: For indoor wet areas (bathrooms, kitchens), look for a tile with a wet DCOF of at least 0.42 (many experts suggest ≥0.60 for added safety margin). For outdoor tiles exposed to rain, pick products with a high-friction surface – typically they’ll have a wet DCOF around 0.6–0.8 or a European rating of R11/R12 for slip resistance.

Q5: How can I check a large porcelain tile for warping before purchase?

A: One easy method is to take two tiles and place them face-to-face, then see if they touch evenly. There should be minimal gaps along the edges. You can also stack tiles back-to-back and check the same way. If possible, ask the supplier for the flatness/warpage test data of that batch as well.

Q6: What are the most common defects found in porcelain tiles?

A: Common issues include color shade variations from tile to tile, incorrect sizing (tiles off in dimensions), and warping (tiles not flat). You might also encounter chipped edges, pinholes or spots in the glaze, hairline cracks, or tiles that stain easily due to a porous glaze. These are signs of lower quality or poor quality control.

Q7: How can I prevent color shading differences and batch inconsistency in my order?

A: Make sure your entire order comes from the same production batch (ask the supplier to confirm the batch number for all boxes). This ensures all tiles are the same shade and caliber. It’s wise to order the full quantity you need (including spares for cuts or future repairs) in one go – that way you won’t have to mix different batches.

Q8: What certifications and test reports should I request, and how do I verify them?

A: Ask for recent third-party test reports showing the tile’s key properties (water absorption, strength, etc.) – these should be done to ISO standards. Also request any market-specific certificates like a CE certificate if you’re importing to Europe. To verify them, check that the reports have an official lab logo or accreditation number (e.g. CNAS or ILAC marks) and ensure the product details on the report match your tile. If needed, you can contact the issuing lab to confirm validity.

Q9: What should I inspect in the packaging and pallets to minimize breakage?

A: Check that the tile cartons are strong (thick cardboard) with proper corner protection and cushioning between tiles. The pallets should be solid and not damaged. All boxes should be stacked neatly with no overhang, strapped tightly with strong bands, and wrapped in shrink film. Good packaging prevents tiles from moving or bumping during transport, which in turn reduces breakage.

Q10: What is the biggest mistake even professional tile buyers make?

A: The biggest mistake is focusing only on the unit price and ignoring the total cost. Cheaper, low-quality tiles might save money upfront, but they can lead to expensive problems – installation failures, high wastage, customer complaints, repairs or early replacement, and damage to your reputation. Investing a bit more in quality tiles from the start is far more cost-effective over the long run.