Problem: B2B importers often struggle to identify reliable ceramic tile suppliers in China.

Agitate: With thousands of factories, choosing the wrong one risks quality issues and delays.

Solution: This guide by an industry insider narrows down China’s top 10 tile manufacturers to simplify your decision-making.

Snippet (Direct Answer): China’s leading ceramic tile manufacturers – such as Dongpeng, New Pearl (Guanzhu), Monalisa, and Marco Polo – dominate the industry with massive production capacities and global quality certifications. Our top 10 list highlights the best Chinese tile suppliers, their FOB price ranges, and key strengths, helping importers find high-quality tiles at competitive prices.

Transition: Updated 2026: The Chinese tile industry remains a global leader – this guide has the latest info to help importers this year. In this comprehensive article, I’ll explain how we selected these top manufacturers, give an overview of China’s ceramic tile industry, profile each of the top 10 companies, compare their key facts in a handy table, and share extra tips – like attending trade fairs (Canton Fair, CeramBath, etc.) – to ensure a smooth tile importing experience. Let’s dive in!

How Did We Select the Top Manufacturers?

Problem: The sheer scale of China’s tile industry means not all suppliers are equal – many buyers feel overwhelmed evaluating countless factories.

Agitate: Without a clear method, you risk picking manufacturers with poor quality control or limited capacity, jeopardizing your projects.

Solution: We applied a rigorous methodology to pinpoint the truly top manufacturers in China’s ceramic tile sector.

Snippet (Methodology Answer): Our selection is based on objective criteria: production capacity, product quality, export experience, certifications (like ISO and CE), innovation, and cost-performance. We analyzed industry reports and leveraged my firsthand knowledge as a China-based tile manufacturer to shortlist companies that consistently excel in quality, scale, and reliability.

Our Selection Criteria

To ensure an authoritative and unbiased list, we focused on measurable factors and industry recognition:

- Production Scale & Capacity: We favored companies with large-scale operations (many production lines or high annual output). For example, some top brands operate dozens of production lines or produce over 50 million square meters of tiles yearly.

- Quality Management & Certifications: Manufacturers had to demonstrate strict quality control. All our top 10 hold certifications like ISO9001 for quality management; many also have ISO14001 (environmental) or CE certification for European standards. This ensures their tiles meet international benchmarks.

- Product Range & Innovation: We looked at the breadth of product offerings (ceramic, porcelain, glazed, polished, large-format slabs, etc.) and the manufacturer’s innovation track record. Several of our picks have hundreds of patents or design awards, indicating a commitment to R\&D.

- Export & Project Experience: Top candidates have a strong export history and experience supplying major projects worldwide. Companies that have supplied tiles for iconic buildings or have a presence in many countries scored extra points. Their familiarity with export logistics and standards makes them reliable partners for importers.

- Cost-Performance: For B2B buyers, competitive pricing is crucial. We chose manufacturers known for high cost-performance – those who can deliver quality tiles at reasonable FOB prices.

- Reputation & Stability: Finally, we considered each company’s industry reputation, years in business, and financial stability. The list includes both long-established brands (some with histories back to the 1970s) and rising modern enterprises, all of whom have proven track records.

By applying these criteria, we ensured only the best of the best made it to the list. Each chosen manufacturer has something exceptional to offer – be it sheer production might, innovative designs, or outstanding value – making them stand out in China’s vast ceramics landscape.

What Should Importers Know About China's Ceramic Tile Industry?

Problem: Importers may not realize just how massive and advanced China’s ceramic tile industry is.

Agitate: Lack of industry knowledge can lead to missteps, like underestimating lead times or missing out on top regional suppliers.

Solution: A brief industry overview will equip you with key facts – from China’s production hubs to market trends – so you can navigate sourcing with confidence.

Snippet (Industry Overview Answer): China is the world’s largest ceramic tile producer and exporter, with an industry centered in Foshan, Guangdong (known as China’s “ceramics capital”). In 2023, Chinese tile exports rebounded to 615 million m², underscoring China’s global dominance. The country boasts thousands of tile factories, modern manufacturing technology, and products ranging from budget tiles to cutting-edge large-format slabs.

Industry Size and Output

It’s hard to overstate the scale of China’s ceramic tile industry. As of 2024, China’s annual production capacity was around 12.2 billion square meters of tiles – an astounding figure that makes China the largest tile manufacturer on the planet. In fact, Chinese factories produce roughly half of the world’s ceramic tiles. This huge output means importers have access to virtually unlimited supply and variety when sourcing from China.

Even after a period of consolidation (with some smaller factories closing to improve environmental compliance), China’s tile output remains dominant. Exports are a significant part of the industry: after a dip in the 2010s, tile exports surged 6.2% in 2023 to about 615 million m², keeping China as the world’s top tile exporter (closely followed by India). Major markets for Chinese tiles include Asia (over 70% of China’s exports), the Middle East, Africa, and Latin America. Domestic consumption is huge as well – China’s booming construction ensures billions of square meters are used at home each year.

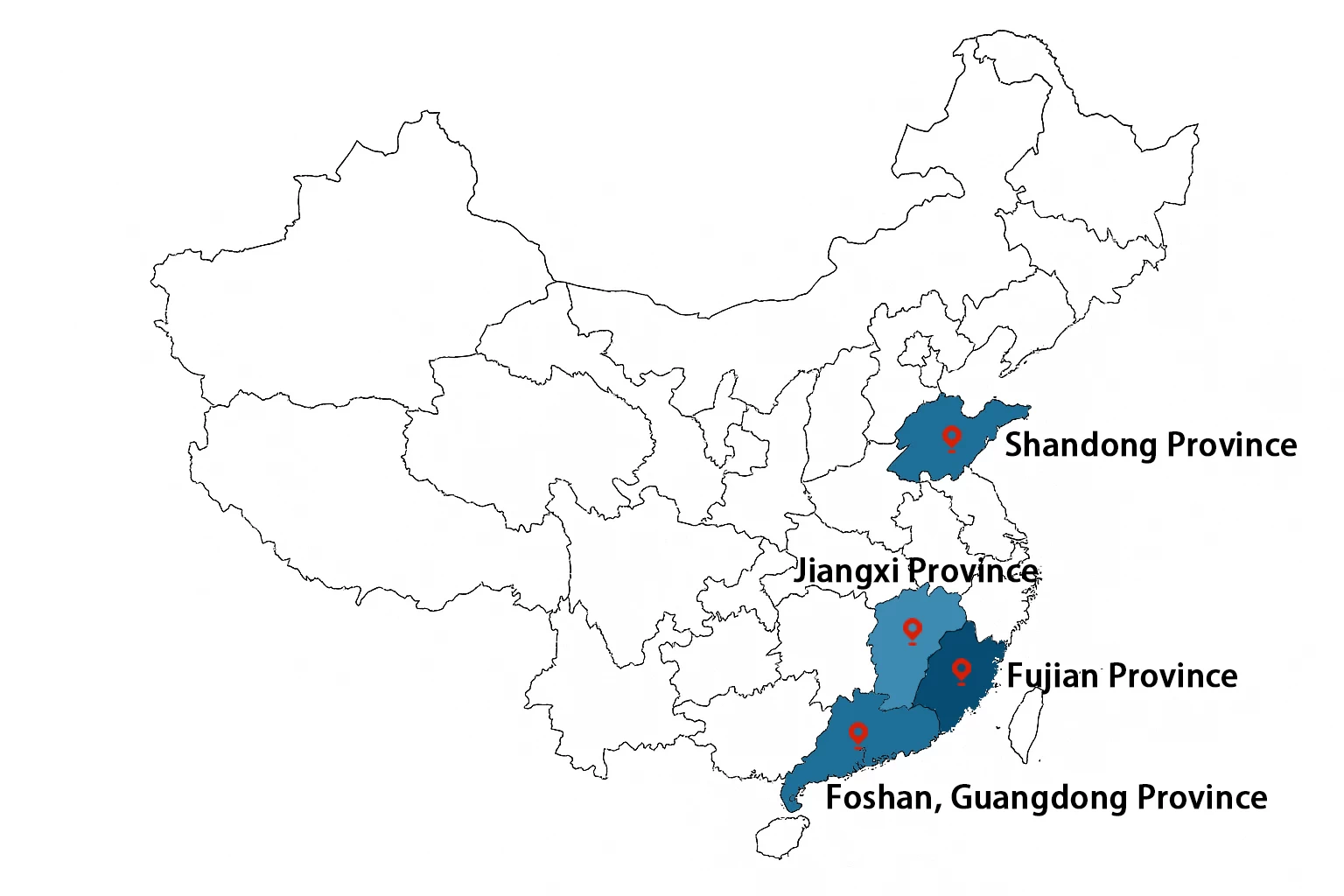

Key Production Hubs

Geography matters in China’s tile industry. Production is concentrated in a few key regions known for ceramics:

- Foshan, Guangdong: The epicenter of ceramic tile manufacturing. Foshan (and neighboring cities like Zhaoqing, Yunfu and Qingyuan) hosts hundreds of tile factories and brand headquarters. It earned the nickname “Ceramics Capital” for its vast cluster of manufacturers and has world-class facilities like the China Ceramics City and the Foshan International Ceramic Exhibition Center. Many of our top 10 manufacturers are based in Foshan.

- Jiangxi Province: Areas like Gao’an have growing tile industries, often focusing on cost-effective production due to cheaper land and energy.

- Shandong Province: Zibo and surrounding areas are known for ceramics and building materials, including some tile output.

- Fujian Province: Fujian (e.g., Jinjiang) also has tile factories, historically known for ceramic roof tiles and now floor tiles.

- Others: Sichuan, Hebei, and Liaoning have a few notable producers, but the bulk is in South China (Guangdong) and parts of East China.

This regional clustering means when you visit Foshan, you can tour dozens of factories and showrooms within a short distance – a huge advantage for importers doing supplier visits.

Industry Trends and Capabilities

China’s tile manufacturers have modernized rapidly. Many factories use advanced Italian and Spanish machinery for pressing, glazing, and firing tiles. Digital inkjet printing technology (for high-resolution tile designs) is ubiquitous, enabling Chinese tiles to mimic natural stone, wood, or any pattern with remarkable realism. Some trends and capabilities importers should note:

- Large Format Tiles & Slabs: Chinese companies have mastered producing large porcelain slabs (e.g., 800×1600mm, 1200×2400mm panels) that are popular for flooring and walls. Brands like Monalisa lead in this area, making giant slabs that rival Italian products.

- Variety of Finishes: Glossy polished porcelain, matte rustic tiles, wood-look planks, mosaic sheets – you name it, Chinese suppliers make it. There are over 2,000 production lines nationwide dedicated to different tile types (polished, glazed, rustic, thin tiles, etc.), which have shifted with demand.

- Innovation & Green Tech: Top brands invest in R\&D for things like antimicrobial tiles, ultra-thin energy-saving tiles, and inkjet techniques. Some have obtained hundreds of patents. Additionally, Chinese tile makers are adopting greener practices – e.g. recycling heat from kilns, water recycling, and obtaining green building material certifications. One top company, Xinruncheng, even earned a “Three-star Green Building Materials” rating for its eco-friendly products.

- Quality Improvement:* There’s a lingering myth that Chinese tiles are lower quality, but in reality many factories meet or exceed European standards. For instance, it’s common for floor tiles to have <0.5% water absorption (porcelain grade) and high breaking strength. Several of our listed manufacturers have won “Top 10 Ceramic Brand” awards in China for quality. As an importer, you can find both economy-grade tiles and premium grade tiles in China – the key is selecting the right manufacturer for your needs.

Overall, China offers an unmatched combination of scale, variety, and cost-effectiveness in ceramic tiles. Understanding this landscape helps you appreciate why the following top 10 companies have risen above the rest – they leverage China’s strengths while maintaining international-level quality and service.

Who Are the Top 10 Ceramic Tile Manufacturers in China?

Problem: Even with industry knowledge, importers face a long list of potential suppliers – who truly are the top 10?

Agitate: Without clear guidance, you might miss out on the best manufacturers or overlook up-and-coming players like Kingsun that offer great value.

Solution: Here we present China’s top 10 ceramic tile manufacturers, each with a profile detailing their strengths, product range, and why they stand out.

Snippet (Top 10 Answer): China’s top 10 tile manufacturers include both household-name brands and high-performing factories. They range from giants like Dongpeng and New Pearl (Guanzhu) – each producing over 50–200 million m² annually – to specialized innovators like Kito and value-driven suppliers like Kingsun. Below, we list the top 10 (in no particular order) and what makes each a go-to choice for B2B tile buyers.

1. Dongpeng Holdings Limited (Dongpeng Group)

Founded: 1972 (headquartered in Foshan, Guangdong)

Overview: Dongpeng is one of China’s most iconic ceramic tile brands. Originally established as a small workshop, it has grown into a powerhouse with 14 production bases and a diversified product portfolio. At the end of 2014, Dongpeng’s capacity reached 50 million m² per year, and it has only expanded since. The company is known for integrating ceramic tiles and sanitary ware – offering one-stop solutions for bathrooms and interiors. Dongpeng tiles are found in homes and commercial projects worldwide, from the US to Australia.

Key Products: Floor and wall tiles (ceramic and porcelain), including polished vitrified tiles, glazed tiles, “antique” (rustic) tiles, and even curtain wall panels. Dongpeng also produces toilets, basins, and faucets, making it a comprehensive building materials supplier. Notably, their crystal porcelain tile series and eco-friendly designs have won acclaim.

Why They’re Top 10: Dongpeng combines massive scale with quality. They hold over 600 patents and helped draft national standards for ceramic tiles – a sign of their leadership in innovation. They implement ISO9001 quality management and pride themselves on green manufacturing and warm customer service. For importers, Dongpeng’s broad distribution (with offices in Hong Kong and abroad) and reliable high-volume supply make them a top choice. When you need a well-established, reputable partner, Dongpeng fits the bill as an industry giant that still puts quality first.

2. Guangdong New Pearl Ceramics Group (Guanzhu Ceramics)

Founded: 1993 (based in Foshan, Guangdong)

Overview: New Pearl is a leading ceramic group encompassing multiple brands – the most famous being Guanzhu Ceramics. With over 18,000 employees and three main subsidiaries (Guangdong NewPearl, Guangdong Summit, Jiangxi NewPearl), the group is truly a titan. Guanzhu, their flagship brand, caters to over one million consumers annually and operates 5 major production bases with 60+ production lines. This enables an astonishing output of more than 200 million m² of tiles per year, making New Pearl one of China’s largest tile manufacturers by volume. New Pearl’s sprawling product lineup covers virtually every type of tile an importer could want.

Key Products: The group produces polished porcelain tiles, glazed tiles, rustic (matte) tiles, ceramic wall tiles, fully vitrified tiles, and even sanitary ware. Sizes range from tiny 23×23 mm mosaics to giant 1.2×1.8 m slabs. They market under many sub-brands – e.g., Guanzhu, Summit, Louis Modern, Mocolor, etc., each targeting different segments from economy to luxury. Guanzhu in particular is known for durable floor tiles and has invested in advanced technology to ensure consistent quality across its huge output.

Why They’re Top 10: Scale and global reach. New Pearl (Guanzhu) is often referred to as a trend-setter and has been recognized among China’s top ceramic brands for many years. Their capacity and range mean importers can source almost any ceramic product from within the group. Despite volume, they maintain standards – evidenced by ISO9001 certification and numerous awards. Guanzhu tiles have been used in high-profile projects, from Burj Khalifa to large shopping malls. For buyers, New Pearl offers the confidence of a supplier that can handle large orders with consistent quality, backed by a strong export team. If you need millions of square meters of tiles, New Pearl/Guanzhu can deliver while also offering diversity in design.

3. Guangdong Monalisa New Materials Group (Monalisa Tiles)

Founded: 1992 (Foshan, Guangdong)

Overview: Monalisa is a pioneer in China’s high-end tile segment, famous for its porcelain slabs and artistic tiles. The company started as a collective factory and transformed into a private enterprise by 1998, eventually listing on the Shenzhen Stock Exchange in 2017. Monalisa (sometimes styled as Mona Lisa) Group specializes in innovative ceramic materials and was among the first in China to produce large-format panels and thin ceramic slabs. With a focus on R\&D, Monalisa has established over 4,000 stores and showrooms nationwide, indicating its strong domestic presence (a plus for stability and after-sales support).

Key Products: Monalisa’s range spans standard ceramic floor and wall tiles to cutting-edge products like rock slab panels, slim porcelain boards, marble-look slabs, and even ceramic art pieces. They produce glazed interior tiles, polished tiles, “archaized” (antique-style) tiles, and mosaics, but their claim to fame is really the big slabs (sometimes branded as “Marmoelite” or seven-star stone series) that can cover entire walls or floors with minimal joints. These large tiles (often in 900×1800 mm or larger) are sought after for luxury projects. Monalisa also pushes eco-friendly innovations, such as photocatalytic tiles that help purify air.

Why They’re Top 10: Monalisa represents the innovative edge of China’s tile industry. They invest heavily in design – every year showcasing new collections that set trends in textures and formats. The company has supplied tiles for prestigious projects like Olympic venues and the Hong Kong–Zhuhai–Macao Bridge, underlining its reliability for complex jobs. Importers who target the higher-end market or need unique formats (like extra-large slabs) will find Monalisa an ideal partner. They offer Western-style quality and aesthetics at competitive prices, and being a publicly listed company adds transparency and credibility. In short, Monalisa is China’s answer to Italy’s luxury tile brands – combining artistry with industrial might.

4. Dongguan Marcopolo Ceramics Co., Ltd. (Marco Polo Tiles)

Founded: 1988 (Dongguan, Guangdong)

Overview: Marco Polo is a well-known Chinese tile brand, often associated with premium design and “cultural ceramics.” The company (part of the Marco Polo Group) built its reputation in the 1990s with high-quality antique-style tiles and has since expanded into a comprehensive tile manufacturer. They have established five major production bases worldwide, signaling both a global vision and significant capacity. Marco Polo’s brand carries weight in China – it’s synonymous with style and was one of the first Chinese tile brands to emphasize branding and showroom experience.

Key Products: Marco Polo offers a vast collection, including matte porcelain tiles, glossy polished tiles, glazed tiles, interior wall tiles, and specialty products like hand-carved tiles and micro-crystal stone tiles. One standout is their independently-developed curved ceramic panels that can bend up to 120° – an innovation useful for cladding columns or curved surfaces. They cover all the main categories of floor and wall tiles, often with an Italian design flair (the company has collaborated with European designers). Popular series include rustic Mediterranean patterns, wood-look tiles, and large ceramic “marble” tiles for floors.

Why They’re Top 10: Marco Polo is renowned for its design excellence and brand prestige. They reportedly hold 570 patents, including nearly 70 invention patents – showing a dedication to new technology and unique designs. The brand has supplied tiles to over 130 countries, and been involved in national landmark projects and World Expo pavilions, underscoring trust from top architects. For importers, Marco Polo is a go-to when the project demands a premium look and feel but still at a better price point than European imports. They have a proven export network and marketing support, which can be beneficial if you plan to retail the brand. With Marco Polo, you get a combination of Chinese efficiency and upscale design.

5. Nabel Ceramic Co., Ltd.

Founded: 1992 (Hangzhou, Zhejiang)

Overview: Nabel is one of the leading tile manufacturers outside of Foshan, demonstrating that top-quality tiles are made beyond Guangdong too. Headquartered in Hangzhou, Nabel has a reputation for high-end materials and innovation. Over nearly 30 years, the company amassed 500+ patents and employs more than 9,000 staff. Nabel’s annual output is around 50 million m² of ceramics, and its products are displayed in over 3,500 showrooms worldwide, reflecting an extensive distribution network. Nabel aims to be the “world’s best supplier for decorative materials,” a vision supported by their emphasis on cutting-edge technology and aesthetic design.

Key Products: Nabel produces a full spectrum of ceramic and porcelain tiles, but is especially known for its porcelain slabs and large floor tiles. Their catalog includes stone-look tiles, wood-look tiles, polished glazed tiles, and even porcelain panels (large thin tiles for walls/floors). Nabel also offers specialty series like carpet-pattern tiles and marble-imitation tiles that are popular in hotels and luxury residences. The company has invested in true-color inkjet printing and precise glazing to achieve very natural textures. In addition to tiles, Nabel manufactures porcelain slab countertops and other architectural ceramics.

Why They’re Top 10: Nabel stands out for its quality and innovation. They were among the first in China to introduce ultra-large slab production and have maintained a strong design ethos. Nabel tiles often feature in high-end projects (luxury retail stores, upscale homes) where buyers seek a distinct, refined look. Importers focusing on quality-conscious clients will appreciate Nabel’s consistency and premium branding. They carry multiple certifications and have won industry awards for technology. Also, being based in the Yangtze River Delta (one of China’s economic cores) gives Nabel logistical advantages for shipping via Shanghai port. In summary, Nabel is a top-tier supplier for those who want “Made in China” quality at its finest, with a bit of exclusivity compared to the more mass-market Foshan brands.

6. Guangdong Kito Ceramics Group

Founded: 2004 (Foshan, Guangdong)

Overview: Kito is a younger entrant that quickly rose to prominence by focusing on top-grade glazed porcelain tiles. In just two decades, Kito expanded to three production bases (Foshan, Jingdezhen, and even one in Malaysia) with 13 production lines and 23+ million m² annual output. Kito positions itself as an innovator and a quality leader, blending advanced manufacturing with creative design. It’s often praised for having a product range that keeps up with global tile trends – from rustic wood-look planks to contemporary slim tiles – while maintaining strict quality control. Kito also diversified into some environmentally friendly building materials, aligning with green building movements.

Key Products: Kito’s lineup includes a wide range of porcelain floor and wall tiles. They are especially known for inkjet-printed tiles that realistically mimic wood, stone, and concrete surfaces. Their product categories span full-polished porcelain, semi-polished (lappato) tiles, matte finish tiles, and textured “rough” surface tiles for outdoor use. Sizes vary from small 100×100 mm mosaics up to large 600×1200 mm slabs. Kito was one of the first in China to heavily adopt digital inkjet printing and dry granule techniques, which allows complex patterns and textures on tiles. Notably, Kito produces wood-look porcelain planks that have been very popular in markets like North America as a durable alternative to hardwood.

Why They’re Top 10: Kito combines design innovation with a focus on quality. They’ve won awards like the “Original Design Product Excellence Award” in China and carry certifications such as ISO14001, CE, and the Hong Kong Q-Mark, indicating international standard compliance. Kito’s tiles have been used in prominent venues (e.g., Shanghai World Expo, Milan Expo pavilions), proving their world-class quality. For importers, Kito offers the reliability of a large manufacturer but with the agility of a design-focused firm. They aren’t as huge as Dongpeng or New Pearl, but that can mean more flexibility in customization and attentive service. If your market values on-trend designs and you want a supplier who can deliver consistent quality (with less risk of factory capacity issues), Kito is an excellent choice.

7. Kingsun Ceramic Factory (Kingsun Tiles)

Founded: 2006 (Foshan, Guangdong)

Overview: Kingsun Ceramic Factory has quickly established itself as a manufacturer known for high cost-performance in the tile market. Operating with two modern production lines, the company maintains a focused scale that enables flexibility and close attention to quality. Kingsun specializes in producing value-oriented porcelain and ceramic tiles with consistent standards that align with international requirements. Over the years, it has served numerous importers and engineering contractors who require dependable quality at accessible prices. One of Kingsun’s key strengths is its customized production approach – allowing adjustments in design, size, and finish to suit different market needs, which is often more difficult for larger-scale operations.

Key Products: Kingsun offers a wide range of ceramic and porcelain floor and wall tiles in various sizes, such as 600×600 mm,600×1200 mm, 900x1800mm, 1200x2400mm, 1600x3200mm... Available finishes include polished, matte, honed, and wood grain... The company is particularly experienced in glazed porcelain tiles that mimic the aesthetics of natural stone or wood, delivering upscale visuals at affordable pricing. Additionally, Kingsun provides ceramic wall tiles in modern formats, including subway and patterned styles. A defining advantage is its flexibility for custom orders – the factory can develop exclusive patterns or specific glazes for clients with reasonable minimum order requirements. The typical FOB pricing ranges from USD \$3–\$25/m², covering economical models up to premium large-format tiles. All products are subjected to strict quality control to ensure compliance with export market standards in water absorption, thickness, color stability, and packaging.

Why They’re Top 10: Kingsun earns its place on this list for offering exceptional value to importers. Its smaller scale enables personalized service and greater responsiveness, which many value-driven buyers appreciate. The factory holds ISO9001 certification and ensures that its tiles meet both CE standards for Europe and INEN benchmarks for the American Countries. Kingsun also has experience supplying tiles for large-scale housing and commercial projects, where cost-efficiency and timely delivery were crucial. This makes the company a suitable partner for distributors, wholesalers, and developers looking for dependable supply without the markup of major brands. Overall, Kingsun stands out as a flexible, export-focused factory delivering consistent quality and customized solutions at competitive prices.

8. Foshan Shiwan Eagle Brand Ceramics Ltd. (Eagle Ceramics)

Founded: 1974 (Foshan, Guangdong)

Overview: Eagle Brand (often just called “Eagle Ceramics”) is one of the oldest and most respected names in China’s tile industry. With over 40 years of history, Eagle has become an internationally recognized ceramic enterprise, known for solid quality and classic designs. The company has 4 major production bases in Guangdong (including the famous Shiwan district, a historic ceramics center) and an extensive domestic distribution network. Eagle Brand has also been at the forefront of China’s industry globalization – it was one of the first Chinese tile companies to exhibit at Italy’s Cersaie/Bologna Ceramic Fair (attending 17 consecutive years since 1998). This long-term exposure to global markets means Eagle understands international standards and tastes well.

Key Products: Eagle Ceramics produces a wide array of tiles: polished porcelains, glazed floor tiles, interior wall tiles, fully polished glazed tiles, and even some unique composite ceramic products. They are especially known for their polished tiles (sometimes branded under series like “Soluble Salt” or “Double Loading” for older tech and newer nano-polished porcelains). Eagle also offers glazed rustic tiles and ceramic mosaics for walls. Their designs tend to be classic and timeless – lots of marble-look and granite-look tiles suited for both commercial and residential projects. The quality of Eagle tiles is consistently high in terms of flatness, polish, and durability (many builders in China swear by Eagle for large projects).

Why They’re Top 10: Heritage and reliability best describe Eagle Brand. They have earned titles like “China Famous Brand Product” and been listed among “China’s 500 Most Valuable Brands”, reflecting strong brand equity. For importers, working with Eagle is reassuring – this is a company with decades of export experience (their tiles have reached over 100 countries) and comprehensive certifications: ISO9001 for quality, China’s 3C compulsory certification, and environmental product certifications. Eagle’s technical expertise is notable too; they maintain strict quality labs and were early adopters of modern tile tech in China. If you seek a proven partner for consistent supply, Eagle is a top contender. They might not always have the flashiest new design, but you can trust the tiles will meet specs and that the company will stand behind its product – a crucial factor for long-term import deals.

9. Guangdong New Zhong Yuan Ceramics Group (New Zhong Yuan)

Founded: 1984 (Foshan, Guangdong)

Overview: New Zhong Yuan is often credited as one of the largest ceramic tile manufacturers in China. The group has a slightly complex structure: it started in Foshan’s Nanzhuang (a pottery hub) and grew into a conglomerate with multiple production bases (11 major manufacturing sites across China, and even factories overseas in places like the Philippines and Uzbekistan). By 2020, New Zhong Yuan was aiming to open 300 specialty shops worldwide, signifying its global ambition. The group’s scale is immense – brand value was reported over 26 billion RMB – and it has over a thousand patents, indicating a focus on innovation. New Zhong Yuan operates several brands (some export under names like “NCC Xinyuan”) and is known for both ceramic tiles and engineered stone products.

Key Products: New Zhong Yuan produces ceramic floor and wall tiles, polished vitrified tiles, rustic tiles, exterior facade tiles, and sanitaryware. Essentially, they cover every category, from basic economical tiles to premium large slabs. One area of specialty is engineering tiles – they supply a lot of tiles for public infrastructure, airports, shopping centers, etc., where durable large quantities are needed. They also have a line of quartz stone slabs (for countertops) and artificial stone tiles. The product breadth is huge; an importer can source matte porcelain for one project and heavy-duty 20mm thick outdoor tiles for another, all from New Zhong Yuan. Their factories are equipped for volume – for example, a single base might run 7+ production lines just for one type of tile, ensuring bulk orders can be met quickly.

Why They’re Top 10: New Zhong Yuan is all about massive capacity and comprehensive supply. They have a significant global presence, exporting to Asia, Europe, the Americas, Africa – practically everywhere. Importers who need a one-stop shop for different types of tiles, or who require a supplier capable of extremely large orders, will find New Zhong Yuan very attractive. They hold ISO9001 certification and have a long-standing reputation. The group’s products have been used in landmarks (reportedly even the Porsche Design Tower in Miami and China National Radio building, among others). While perhaps less of a “consumer brand” internationally, within industry circles New Zhong Yuan is respected as a genuine giant – often behind the scenes supplying OEM tiles to other brands as well. Choosing them means tapping into one of China’s most powerful tile production networks. Just be aware that with size comes bureaucracy; having a good contact or agent can help navigate such a large organization.

10. Guangdong Xinruncheng Ceramics Co., Ltd. (XRC Tiles)

Founded: 1998 (Foshan, Guangdong)

Overview: Xinruncheng (often abbreviated XRC) is a modern ceramic enterprise that, while not a household name abroad, ranks among China’s top producers. The company’s roots actually trace back to 1970 via a predecessor factory, but officially Xinruncheng was established in 1998. They operate two large-scale “garden style” factories in Foshan covering 500,000+ square meters, indicating substantial capacity. XRC has grown quietly but impressively – focusing on producing quality tiles that have gained them partnerships in over 70 countries. They emphasize technology and environmental responsibility; for instance, they’ve earned a national green building material label for some of their products.

Key Products: Xinruncheng offers a diverse range of glazed porcelain tiles, polished porcelain tiles, and ceramic wall tiles for various applications. Their designs cover all the basics – marble patterns, wood looks, solid color tiles, etc. – in sizes typically from 300×300 mm small tiles up to around 900×1800 mm large panels. They keep up with trends, producing thin porcelain slabs and upscale glazed tiles as demand evolves. One notable aspect is their incorporation of antimicrobial and negative ion technology in some tiles, catering to health-conscious building trends. This means certain XRC tiles can inhibit bacterial growth or improve indoor air (features that can be marketing points in projects like hospitals or green buildings).

Why They’re Top 10: Xinruncheng is a prime example of a high-quality manufacturer that doesn’t always seek the spotlight, yet delivers great value. They have a strong R\&D team and have made significant innovations (patents in functional ceramics). For importers, XRC can be a gem: they offer many of the advantages of bigger brands (modern production, reliable quality control, international certifications) but often at slightly lower cost because they’re not spending as much on global marketing. Essentially, you can think of XRC as a strategic supplier – they can do OEM production or adapt to specific market needs. They have experience with private labeling for foreign clients. If you’re looking for a partner who is serious about long-term cooperation and can supply a wide variety of tiles (with an eye on sustainability and new tech), Xinruncheng is well worth considering among China’s best.

Comparison: How Do China’s Top 10 Tile Manufacturers Stack Up?

Problem: Knowing each company’s story is useful, but importers also need a clear side-by-side comparison of key facts – capacity, pricing, product focus – to make decisions.

Agitate: It can be time-consuming to extract data points from profiles.

Solution: The following comparison table distills essential info about the top 10 Chinese tile manufacturers, helping you quickly gauge which might suit your needs best.

Snippet (Comparison Answer): The table below summarizes critical factors for each of the top 10 manufacturers – year founded, location, scale of production, typical FOB price range, product specializations, and certifications. Use it to identify, for example, who has the largest capacity or who offers the lowest prices. This quick reference makes it easier to shortlist which factories to approach for quotations.

| Manufacturer | Founded | Location | Scale (Capacity/Lines) | FOB Price Range (USD/m²) | Key Products | Certifications |

|---|---|---|---|---|---|---|

| Dongpeng Group | 1972 | Foshan, Guangdong | \~50 M m²/year | \$5.5 – \$33 | Ceramic & porcelain tiles; sanitary ware | ISO9001; ISO14001; CE |

| New Pearl (Guanzhu) | 1993 | Foshan, Guangdong | >200 M m²/year | \$4.4 – \$22 | Floor & wall tiles; polished, rustic; sanitary ware | ISO9001; ISO14001; CE |

| Monalisa Group | 1992 | Foshan, Guangdong | — (Large, listed company) | \$5.5 – \$33 | Porcelain slabs; large panels; art tiles | ISO9001; Green Label (China) |

| Marcopolo | 1988 | Dongguan, Guangdong | 5 bases (global) | \$4.4 – \$27.5 | Glazed & polished tiles; antique-style; curved panels | ISO9001; ISO14001 |

| Nabel Ceramics | 1992 | Hangzhou, Zhejiang | \~50 M m²/year | \$5.5 – \$22 | High-end ceramic & porcelain tiles; slabs | ISO9001; ISO14001; CE |

| Kito Ceramics | 2004 | Foshan, Guangdong | 13 lines (\~23 M m²/yr) | \$6.6 – \$22 | Glazed porcelain; inkjet wood & stone tiles | ISO9001; ISO14001; CE |

| Kingsun | 2006 | Foshan, Guangdong | \~20 M m²/year | \$3.3 – \$27.5 | Ceramic & porcelain tiles (custom designs) | ISO9001; CE |

| Eagle Ceramics | 1974 | Foshan, Guangdong | 4 bases (multiple lines) | \$4.4 – \$16.5 | Polished, glazed tiles; interior wall tiles | ISO9001; 3C (China); CE |

| New Zhong Yuan | 1984 | Foshan, Guangdong | 11 bases (100M+ m²/yr approx.) | \$5.5 – \$13.5 | Floor & wall tiles; exterior tiles; quartz stone | ISO9001; ISO14001 |

| Xinruncheng (XRC) | 1998 | Foshan, Guangdong | 2 bases (\~500k m² factory area) | \$4.4 – \$17.5 | Glazed & polished tiles; full range designs | ISO9001; Green Certified |

Notes: FOB price ranges are indicative; actual quotes depend on tile type, size, and order volume. All listed companies export worldwide, so they typically offer international standards compliance. “Scale” is based on available data (annual output in square meters or number of production lines). Kingsun, while smaller in scale, is highlighted for its flexibility and cost-performance. Each manufacturer above has a presence in major trade fairs and can provide samples/catalogs upon request.

From this comparison, you can see at a glance, for example, that New Pearl (Guanzhu) has one of the highest capacities, while Kingsun and Xinruncheng offer some of the lowest price ranges (aimed at value markets). Dongpeng, Monalisa, Marcopolo, and Nabel cater more to the mid-high end with broader design selections and higher price points. Eagle and New Zhong Yuan are stalwarts known for reliability and volume supply. This diversity means whatever your project or market segment – be it budget residential tiles or luxury slabs – there is a Chinese manufacturer in this top 10 list suited for it.

What Are Some Tips for Importing Tiles from China?

Problem: Sourcing tiles from China can be complex for first-timers – from finding suppliers to managing quality and logistics.

Agitate: Without proper guidance, importers might face challenges like communication gaps, shipping delays, or customs hurdles.

Solution: Here are practical tips, drawn from my experience, to help you navigate the importing process smoothly – including leveraging trade fairs, handling samples, and ensuring compliance.

Snippet (Tips Answer): To import tiles successfully, do your homework and use China’s resources: visit major trade fairs (like Canton Fair and CeramBath) to meet suppliers, always request samples or small trial orders for quality checks, clarify certifications and standards needed for your market, and plan logistics carefully (tiles are heavy!). Partner with a reliable freight forwarder and consider a sourcing agent if needed. These steps will save you time and money in the long run.

1. Attend Key Trade Fairs to Find Suppliers

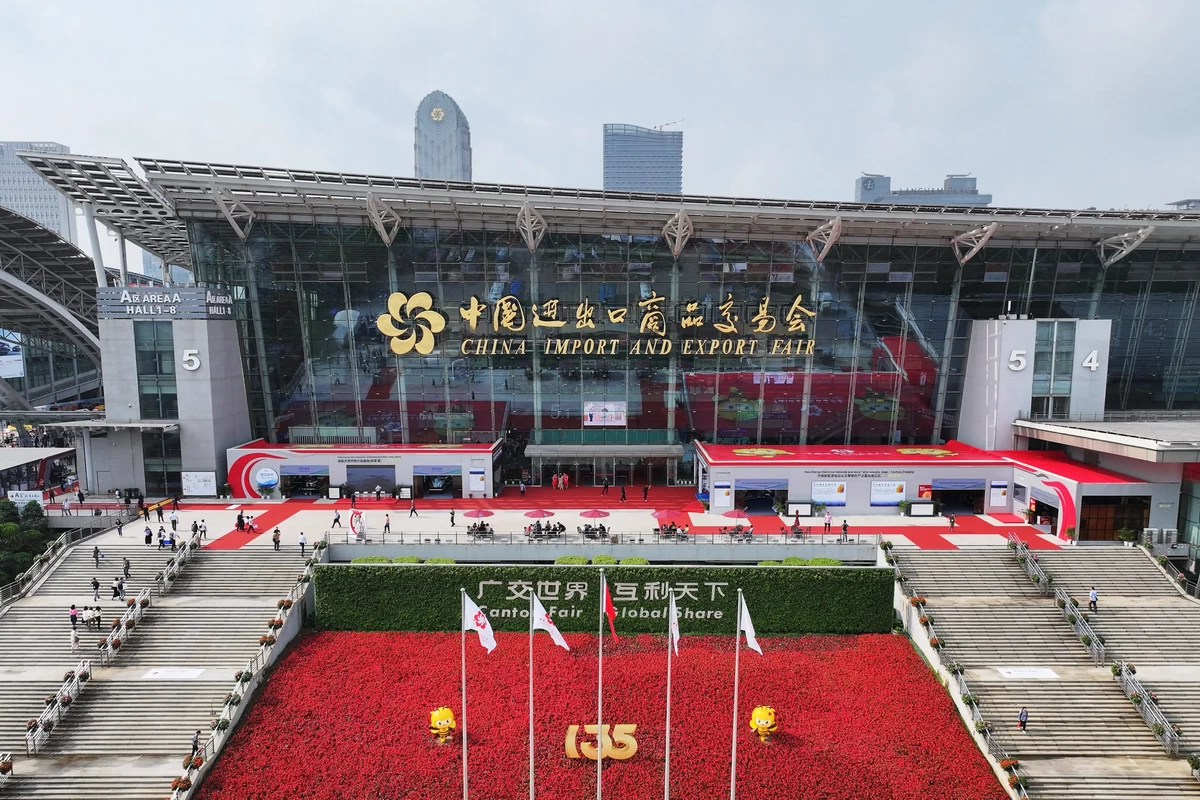

One of the best ways to connect with multiple tile manufacturers quickly is by visiting China’s trade fairs for ceramics and building materials:

-

Canton Fair (China Import and Export Fair) – Held biannually in Guangzhou (usually April and October), this massive trade fair has a Building Materials section where dozens of tile suppliers exhibit. At Canton Fair, you can meet sales reps of major companies (including some of our top 10) and see their tile samples in person. It’s an efficient way to compare quality and prices on the spot. Tip: go in Phase 1 of the fair, which typically includes construction materials.

-

CeramBath (China International Ceramic & Bathroom Fair, Foshan) – This is a specialized tile and bathroom trade show in Foshan, held twice a year (April and October, often overlapping with Canton Fair timing). It’s known as “Asia’s No.1 Ceramic & Bathroom Fair” with 800+ exhibitors. The fair takes place across venues like China Ceramics City and Foshan International Ceramics Expo Center – essentially right in the heart of the tile manufacturing region. Here you’ll encounter nearly all top Chinese tile brands in one place. Walking the show, you can discover new designs, collect catalogs, and directly talk about MOQs and FOB prices. Since Foshan is home to many factories, you can also arrange plant visits before/after the fair (many companies offer shuttle buses from the fair to their factories or showrooms).

-

Regional Export Shows – Sometimes Chinese tile suppliers attend international exhibitions like Coverings (USA) or CERSAIE (Italy). If you can’t travel to China, visiting these international shows could connect you to Chinese exhibitors. However, the largest selection will always be in China.

By attending fairs, you not only find suppliers but also get a sense of new trends (e.g., this year you might see a lot of terrazzo-look tiles or new anti-slip glazes). Bring a notebook or use your phone to jot down booth numbers and contact info, because you will talk to many people. Collect business cards and brochures. After the fair, follow up promptly – Chinese suppliers are very responsive to potential customers met at fairs.

2. Request Samples and Do Quality Checks

Once you have a shortlist of potential manufacturers (whether found via fairs or online), always request samples. Tile colors and textures can look different in person than in pictures. Ask the supplier to send you a few pieces of the tiles you’re interested in. You might need to pay the courier cost, but it’s worth it. Inspect samples for:

- Color & Design: Check that the color meets your expectation and that there’s consistency if you put multiple pieces together. For patterned tiles, see that the print quality is sharp.

- Quality Traits: For porcelain tiles, you can perform a simple water absorption test (porcelain should absorb <0.5% moisture – you can drop some water on the unglazed back and see if it’s quickly absorbed or not). Check tile flatness by placing two tiles face to face to see if they rock (indicating warping). Also examine the glaze surface for pinholes or defects.

- Thickness & Strength: Measure the thickness; sometimes cheaper tiles skimp a bit on thickness which can affect strength. You can do an informal strength test by trying to support a tile at two ends and add a weight in the middle to see if it breaks – but be careful and use proper safety if so. Most important, ensure the tiles meet any specific standards your country requires (like PEI ratings for wear, slip resistance ratings if for floor, etc.). You may ask the supplier for test reports or certifications for the specific model.

If an order is large, consider hiring a third-party inspection service in China. Companies like SGS, BV, or AsiaInspection can go to the factory and do a pre-shipment inspection – checking random samples from the batch for defects, verifying packaging, etc. This typically costs a few hundred dollars, and can save you a lot by catching issues before tiles leave China.

3. Clarify Standards and Certifications

Different markets have different requirements. Communicate your market’s needs clearly to the supplier:

- Certifications: If you need ISO-certified products or specific eco-labels, make sure the supplier has them. For example, CE marking for Europe is essential (most big Chinese factories have CE for their tile models, which covers basics like dimensional tolerance, breaking strength, and slip resistance). If selling in the US, ask if they’ve done ASTM tests for water absorption, DCOF (slip), etc. Some countries in Middle East might require SASO certification (for Saudi Arabia) or similar – Chinese suppliers can often arrange these if informed.

- Anti-Dumping Duties: Tariff policies vary significantly across markets and should be closely monitored. Some regions, including the EU, Indonesia, and several Middle Eastern countries, have implemented anti-dumping duties on Chinese ceramic tiles. While some large Chinese manufacturers have obtained preferential or lower tax rates, the specifics differ from case to case. Importers are advised to discuss with their suppliers whether their products fall under reduced-duty categories or are subject to full rates. These regulations are subject to frequent changes, and even currently (as of 2025), U.S. import duties remain in flux due to policy shifts. It's crucial to verify applicable duties before confirming an order, as taxes can significantly affect total landed cost.

- Labeling and Cartons: Tell the supplier how you need the cartons labeled. They usually have standard export packaging (with neutral English descriptions, tile code, made in China, etc.). If you need your brand on the boxes, many factories will do OEM printing if volume is sufficient. Also specify if you need pallets for easier handling – most will palletize the tile boxes (worth it for easier unloading, even though it adds a bit to cost and weight).

- Standards Compliance: If your project requires specific standards (e.g., ISO 10545 tests results), ask the factory to provide those. Most big manufacturers have lab test data for water absorption, modulus of rupture, abrasion resistance (PEI rating), etc., for each product line. It can be a red flag if a supplier can’t provide any technical data sheet.

4. Negotiate MOQs and Pricing Wisely

Chinese tile manufacturers typically price by square meter (or square foot) FOB. Here are some negotiation tips:

- MOQ (Minimum Order Quantity): The recommended minimum order is typically 1×20’ container, especially for porcelain and ceramic tiles. Since tiles are fragile and heavy, a full container load (FCL) is strongly advised to minimize the risk of breakage and reduce shipping cost per unit. Many factories allow mixing multiple designs within one container, provided each model meets a minimum quantity (often 500-600 m² per design). For importers with limited demand, it’s still worth asking suppliers about ready-stock lots, or consider working with a consolidator who can combine smaller orders – though this adds cost and complexity.

- Pricing: Always clarify what’s included in the FOB price. FOB usually covers the tile cost including export packaging and delivery to the port in China. Check which port – Foshan factories often quote FOB Foshan. For a factory in Hangzhou like Nabel, FOB Shanghai or Ningbo might be used. If you need CIF (cost including sea freight to your port), you can ask for a separate quote, but it’s often cheaper to handle freight yourself or via your freight forwarder. Compare prices among similar quality suppliers. If one is significantly lower, confirm that the specs are truly equivalent (thickness, grade, etc.). Chinese suppliers expect some negotiation, but keep it reasonable – margins on tiles aren’t huge, so don’t expect 50% discounts. Instead, negotiate on payment terms or slight adjustments (like throwing in a few extra spare boxes for free, or upgrading packaging).

- Payment Terms: For first-time or small-volume buyers, the standard payment term across most tile factories is 30% deposit and 70% balance before loading. This protects the factory from non-payment while managing cash flow. Once a long-term, stable relationship is built, some suppliers may accept more flexible terms, such as balance against copy of Bill of Lading (B/L), or reduced deposits (e.g., 15%). For added security, buyers can explore Letter of Credit (L/C) options, although many smaller factories prefer to avoid the complexity of L/Cs. In all cases, verify that payments are sent to the correct company account to prevent fraud.

5. Plan Logistics and Shipping Carefully

Tiles are heavy and relatively low-value per unit weight, which means logistics are a big part of cost. Some tips:

- Full Container Loads (FCL) are Best: Shipping a full 20-foot container (around 27–28 tons max, roughly 1,000–1,300 m² of tiles depending on thickness and size) is more cost-effective than LCL (Less than Container Load). If you can, try to bundle orders to fill a container. It reduces risk of damage (container just has your goods) and lowers freight cost per unit. A 40-foot container can take about double the volume, but note that weight, not volume, often maxes out first with tiles – you might not fully stuff a 40’ because of the 28 ton limit.

- Packing: Ensure the factory pallets the tiles if you need – palletized cargo is easier to unload with a forklift. However, pallet wood needs fumigation certification (the factory will handle that). Some importers choose floor-loading (no pallets, more boxes per container) to maximize quantity, but then unloading is manual. Weigh the pros/cons for your situation.

- Insurance: Marine insurance for tiles is relatively cheap – get it. It covers damages in transit (tiles can crack if a container is mishandled). Also, inspect the container when it arrives. If any pallet or box is crushed, document it and claim if needed. Good suppliers will usually provide some extra tiles or spare boxes to account for potential breakage. Typically breakage is low (tiles are packed well), but you might see 1-2% damage in a long journey – factor that in your ordering (order a little extra).

- Customs and Import Docs: Make sure the supplier provides all necessary documents: commercial invoice, packing list, bill of lading, certificate of origin (especially if your country has a tariff preference or requirement; e.g., some countries in Southeast Asia have Form E for China-ASEAN, etc.), and any certifications required (like CE declaration). Tiles are generally straightforward to import as they aren’t dangerous or perishable – but check if your country requires an import license for ceramics or any standards (for example, some countries have quality standards that might need a local test – rare for tiles, but worth confirming).

- Lead Times: Production lead time for tiles can range from 2 weeks (if items are in stock or common) to 4-6 weeks (for large orders or made-to-order designs). Shipping by sea can take another 2-6 weeks depending on your location. So plan your inventory with a comfortable buffer. It’s wise to schedule orders such that you’re not in a rush – expediting tile production is hard, as kiln schedules are fixed and you can’t speed up ceramic firing by much. If timing is tight, ask the supplier about any ready stock they have (sometimes they have overruns or inventory of popular items that can ship immediately).

6. Communication and Cultural Tips

Dealing with Chinese suppliers is generally straightforward, but a few cultural etiquette and practical tips help:

- Use WeChat or Email: Chinese business people widely use WeChat (an app) for communication. It’s often faster than email for clarifications or quick questions, and supports sending pictures (like you can ask for photos of your products during production or before shipping). Establish a communication line on WeChat or WhatsApp once you’re serious with a supplier.

- Be Clear and Detailed: If you have specific requirements (e.g., “tiles must all be from same caliber/size batch” or “no pattern repetition in a box”), state it clearly. Don’t assume something is understood. Language is usually not a big barrier in the tile export industry (most sales reps read/write English decently), but simple, concise instructions help avoid confusion.

- Build Relationship: Chinese suppliers appreciate long-term relationships. If you plan to import regularly, it’s good to occasionally visit the factory (if possible) or at least maintain friendly communication (send New Year greetings, etc.). These gestures can sometimes lead to better prioritization of your orders or small favors like faster sampling.

- Payments & Trust: Only transfer money to the company’s account as given on invoice (beware of phishing – confirm bank details via a known contact). The big companies in our top 10 are trustworthy, but generally for new suppliers, a 30% deposit is a reasonable risk. As a tip, you could negotiate to hold the final 70% until you see a copy of Bill of Lading – that’s common practice and protects you because it means goods are already shipped out when you pay the balance.

By following these tips – leveraging fairs, vetting quality, understanding terms, and maintaining good logistics and communication practices – you will greatly smooth out the process of importing tiles from China. Many successful importers have built their tile business on Chinese supply, and with the information from this guide, you are well positioned to join them in sourcing excellent tiles at competitive prices.

Conclusion

Importing ceramic tiles from China can be a highly rewarding venture for B2B buyers – as long as you work with the right manufacturers and approach the process informed. In this article, we identified the Top 10 Ceramic Tile Manufacturers in China, ranging from industry titans like Dongpeng and New Pearl (Guanzhu) with enormous outputs, to specialized innovators like Monalisa and Kito, and value-driven suppliers like Kingsun. Each offers unique strengths, whether it’s massive capacity, cutting-edge designs, or flexible customization. China’s ceramic tile industry – anchored in places like Foshan – provides unparalleled variety and scale, making it possible to find tiles for virtually any project or market segment.

As an industry insider, my advice is to do thorough due diligence: leverage trade shows, compare multiple suppliers, and always check quality through samples or inspections. Use the comparison table and profiles here as a starting point for your supplier shortlist. Once you establish a relationship with a reliable Chinese manufacturer, you’ll likely find them to be responsive, efficient, and keen for long-term cooperation. From negotiating a good FOB price to ensuring on-time delivery, the top manufacturers have the experience to meet B2B buyers’ needs – and they’ve been doing so globally for decades.

In summary, China remains the go-to source for ceramic tiles thanks to its combination of quality, innovation, and cost-effectiveness. By partnering with one of the top 10 manufacturers we’ve covered (and applying the importing tips provided), you can confidently import tiles that will delight your customers and underpin the success of your projects. Here’s to building strong, tiled foundations for your business – with a little help from the Middle Kingdom’s finest tile makers!

FAQ: China Tile Wholesale & Sourcing Questions

Q: How can I verify the quality of tiles from a China ceramic tile manufacturer?

A: Request tile samples and inspect them in person to confirm surface finish, shade consistency, caliber, and overall quality. Ask the China ceramic tile manufacturer to provide a Technical Data Sheet (TDS) and verify key specifications (e.g., water absorption, breaking strength, PEI rating, slip resistance) match your project requirements. For large China tile wholesale orders, arrange a third-party inspection (such as SGS or equivalent) to check quality, packing, and compliance before shipment.

Q: What is the typical minimum order quantity (MOQ) for China tile suppliers?

A: MOQ requirements vary by supplier. Large manufacturers often ask for a full container load (for instance, 1000-1300 square meters or one 20-foot container) as a minimum for wholesale orders. Some smaller factories or suppliers may accept lower MOQs or trial orders, especially for new customers or customized products, but larger orders generally get you better pricing.

Q: Can Chinese tile manufacturers create custom designs or offer OEM services?

A: Yes, many Chinese tile manufacturers offer OEM and custom-design services. If you have specific tile designs, sizes, or branding requirements, a capable supplier can produce tiles to your specifications and even package them under your own brand. Factories typically welcome custom orders, but expect to meet a reasonable MOQ and provide clear design details for them to work with.

Q: How do I choose a reliable China tile supplier?

A: To find a reliable China tile supplier, start by researching the company’s background and reputation. Look for a manufacturer with years of experience, relevant certifications, and positive feedback from other international buyers. Reliable suppliers communicate clearly and may welcome factory visits or third-party audits. It’s also wise to begin with a smaller trial order to test their quality and service before placing a larger wholesale order.

Q: What pricing and payment terms can I expect for China tile wholesale orders?

A: Chinese tile suppliers offer competitive pricing for bulk orders, with costs per square meter often lower than local suppliers in Western countries. You can usually negotiate better rates for larger volumes—the bigger the order, the lower the price per tile. Common payment terms are a bank wire transfer (T/T), typically 30% deposit upfront and 70% balance before shipment, or a letter of credit (L/C) for very large contracts. Always clarify what’s included in the price (e.g. packaging, loading) and confirm payment terms in the proforma invoice.

Q: How do Chinese ceramic tile factories ensure consistent quality and standards?

A: Established Chinese tile factories maintain strict quality control processes to ensure consistency. They have QC teams inspecting tiles at multiple stages—checking raw materials, supervising kiln temperatures, and testing finished tiles for defects or color consistency. Many factories also adhere to international standards (like ISO 9001) and perform lab tests on their tiles (for water absorption, strength, etc.) to meet export requirements. As a buyer, you can request QC reports or even hire a third-party inspector to verify quality before shipment.

Q: Can I get product samples or visit a China tile factory before placing a large order?

A: Absolutely. Most Chinese tile suppliers are willing to send samples (often with the buyer covering shipping) so you can assess tile quality and design. Visiting the manufacturer’s factory or showroom in China (for example, in Foshan’s tile hub) is also encouraged and gives you a firsthand look at their operations. If you cannot travel, you can often connect with suppliers at international trade fairs or request a virtual factory tour to build trust before a big order.

Q: What types of tiles can I source from a China porcelain tile factory?

A: Chinese manufacturers produce almost every type of tile you might need. A China porcelain tile factory will supply porcelain floor and wall tiles (which are a type of ceramic tile known for low water absorption and high durability), and most also produce standard ceramic tiles. In addition, you can source glazed tiles, polished vitrified tiles, mosaics, large-format slabs, rustic outdoor tiles, and more from China. The industry is very diverse, so whether you need budget basic tiles or premium designer styles, you can find a supplier in China that offers it.

Q: Do Chinese tile suppliers support long-term partnerships and branding?

A: Yes, the majority of Chinese tile suppliers welcome long-term partnerships and can support your branding goals. Once you establish a relationship, many manufacturers will produce tiles under your private label or brand and ensure consistency in product quality and design over time. They value repeat business, so a reliable supplier will strive to meet your needs consistently and may even offer better pricing or flexible terms for loyal customers. Building a strong partnership with a supplier helps both parties grow together.

Q: For HS codes 69072190, 69072290, and 69072390, will the export price from a China Ceramic Tile Manufacturer/Exporter increase after April 1, 2026 due to the VAT export rebate cancellation?

A: Yes — for these HS codes, the policy change is clear and date-based. China MOF & STA Announcement 2026 No. 2 states that starting April 1, 2026, VAT export rebates will be cancelled for the products listed in Attachment 1, and the export rebate treatment is determined by the export date shown on the customs export declaration.

The product list explicitly includes HS 69072190, 69072290, and 69072390. (Main H.S.Code for Ceramic & Porcelain Tile Products)

Commercial impact (what buyers should expect): Because the rebate for these HS codes becomes 0% for declarations dated on/after April 1, 2026, most China Tile Suppliers / China Porcelain Tile Factories / China Tile Wholesale exporters will adjust their export quotes upward to reflect the lost rebate value (often high single digits, commonly discussed as ~8–10%, depending on how the supplier priced previously and your contract terms).