Buyers often ask a direct question: What is the sintered stone price? Factory‐gate export offers from China commonly start from about USD 7.30–13.25 per m² (≈ USD 0.68–1.23 per sq ft) for popular 9–12 mm slabs, based on FOB Foshan terms and premium grade quality. Actual quotes change with size, thickness, finish, color, and customization1. You can request the latest sheet and samples from Miller · Kingsun at miller@kingsuntile.com.

Factory-Gate Export Prices from China (Per m² / Sq ft)

Terms: FOB Foshan

Quality: CE, ISO 10545, Premium Grade

Note: These are start-from prices for stable, mainstream products. Many other sizes and finishes exist between 900×1800 mm and 1600×3200 mm, and from 3 mm to 20 mm. Each option changes cost.

Conversion used: 1 m² = 10.7639 sq ft

| Popular Size & Thickness | Start From (USD / m²) | Start From (USD / sq ft) |

|---|---|---|

| 900×1800×9 mm | 7.30 | 0.68 |

| 900×2700×9 mm | 10.85 | 1.01 |

| 1200×1200×9 mm | 10.76 | 1.00 |

| 1200×2400×9 mm | 7.88 | 0.73 |

| 1600×3200×9 mm | 12.96 | 1.20 |

| 1600×3200×12 mm | 13.25 | 1.23 |

If you need the full catalog or a fast quote sheet, you can email Miller at miller@kingsuntile.com.

Current Market Price Range Worldwide

Importers see different landed costs after ocean freight, insurance, destination charges, duties, and inland delivery. Full-container shipments keep unit costs lower. Small LCL shipments lift costs.

- Southeast Asia (e.g., Indonesia, Singapore): Many buyers land 9–12 mm slabs at about USD 10–18 per m² (≈ USD 0.93–1.67 per sq ft) in full containers. City delivery and port fees add more.

- Australia / New Zealand: Typical landed levels sit about USD 15–28 per m² (≈ USD 1.39–2.60 per sq ft), driven by longer routes and stricter handling.

- Middle East: Buyers often see about USD 12–22 per m² (≈ USD 1.12–2.04 per sq ft) with efficient routes and stable port processes.

- EU: Landed costs often come about USD 16–30 per m² (≈ USD 1.49–2.79 per sq ft). Local anti-dumping rules, duties, and testing can add fees.

- North America: Many importers report about USD 18–34 per m² (≈ USD 1.67–3.16 per sq ft) due to longer transit and inland freight.

These are practical working bands for planning. Your final number depends on container size, mix of sizes, slab protection, local duties, and last-mile delivery.

Price Comparison: Sintered Stone vs. Quartz

- Entry to mid sintered stone (9–12 mm, FOB China): often USD 7–14 per m² (≈ USD 0.65–1.30 per sq ft) for mainstream colors and finishes.

- Engineered quartz (mainly 15–30 mm, FOB China): often higher due to resin content, slab thickness, brand patterns, and polishing time. Many factory-gate offers sit about USD 25–60 per m² (≈ USD 2.32–5.57 per sq ft) and rise with complex veining.

What this means: Sintered stone usually undercuts quartz on raw slab cost at factory gate for comparable decorative looks. Quartz can still win on edge work ease in kitchen shops, which affects installed price, not the slab price.

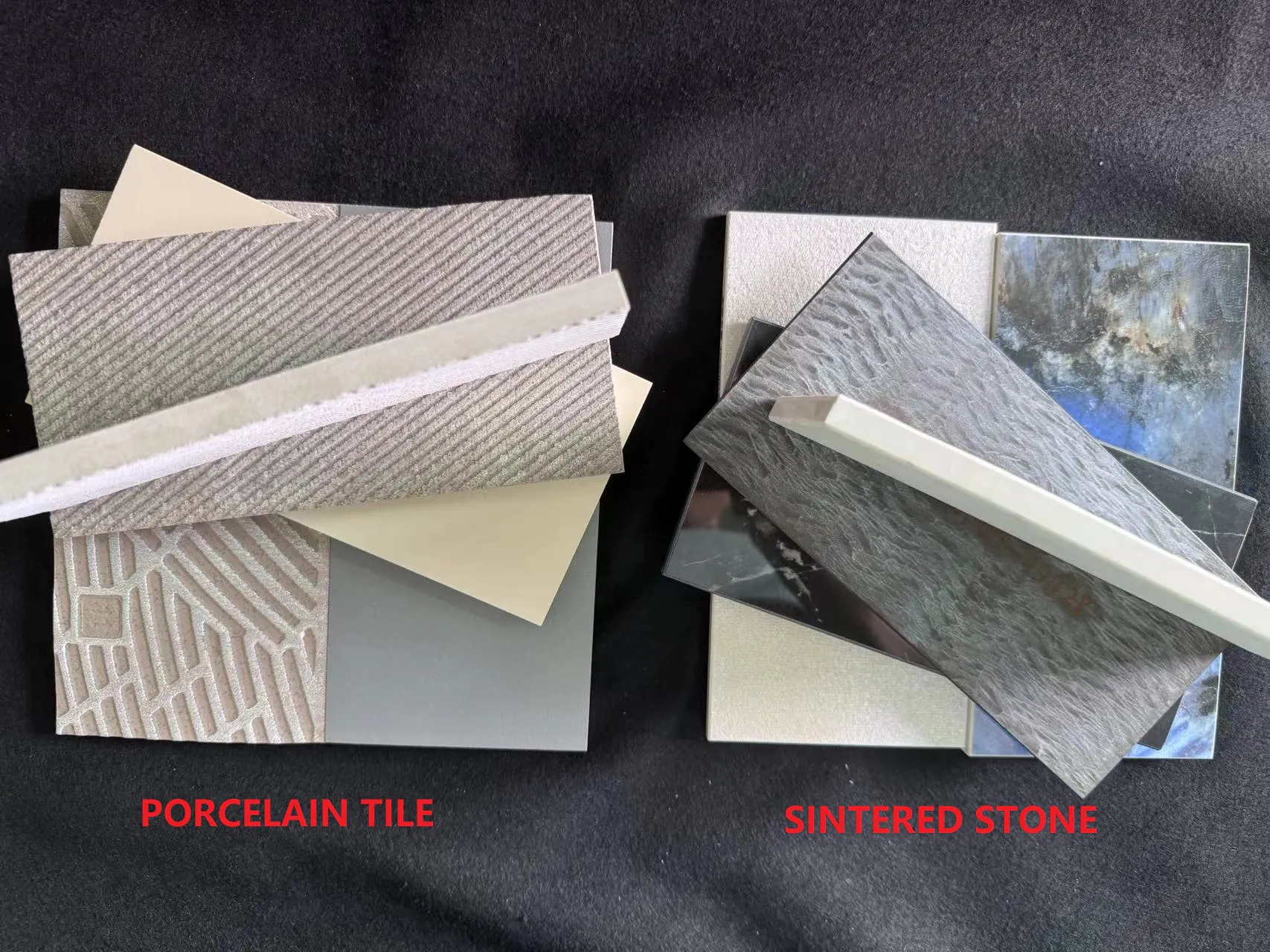

Price Comparison: Sintered Stone vs. Porcelain

Sintered stone2 uses porcelain technology with higher compaction and firing, and it comes in large formats.

- Standard porcelain tiles (e.g., 600×600, 600×1200, FOB China): many lines start about USD 3–8 per m² (≈ USD 0.28–0.74 per sq ft).

- Large-format porcelain / sintered stone slabs (9–12 mm): often USD 7–14 per m² (≈ USD 0.65–1.30 per sq ft).

What this means: Sintered stone costs more than small-format porcelain tiles because large sizes need bigger kilns, special presses, careful handling, and stronger packaging. The gap narrows when you compare big-slab porcelain to sintered stone in the same line.

Factors Influencing Price: Size, Thickness & Customization

Size

- Larger faces raise cost because yield loss and handling risk rise.

- Sizes like 1600×3200 mm need strong packaging and thicker A-frames. That adds cost per m².

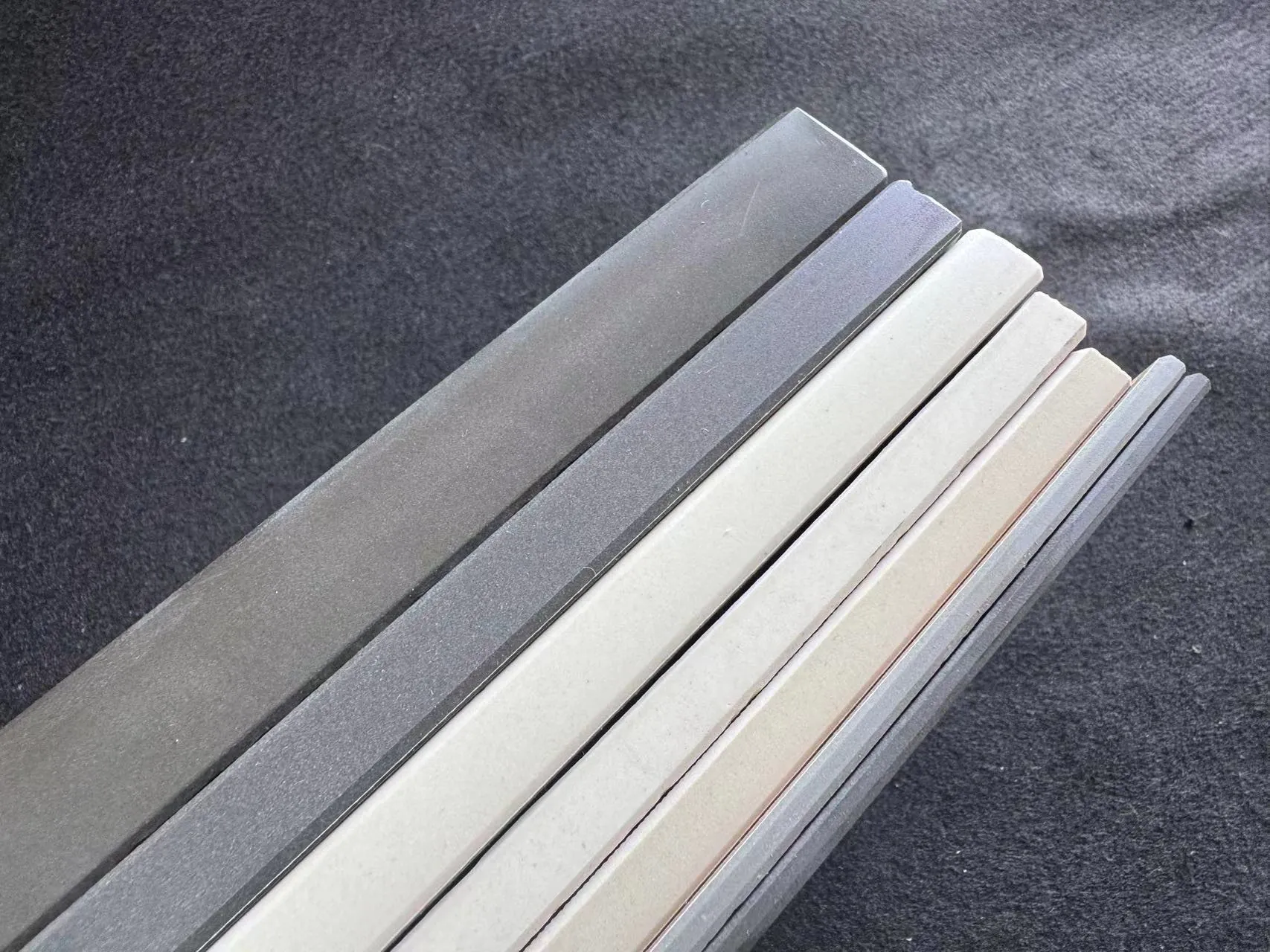

Thickness

- 3–6 mm is thinner, needs higher production technology and precise packing. This makes the price relatively higher.

- 9–12 mm is the mainstream production thickness, widely used for wall and floor installation. It has the most competitive price.

- 18–20 mm requires more raw materials, and higher transport and packing costs, so the price is higher than 9–12 mm.

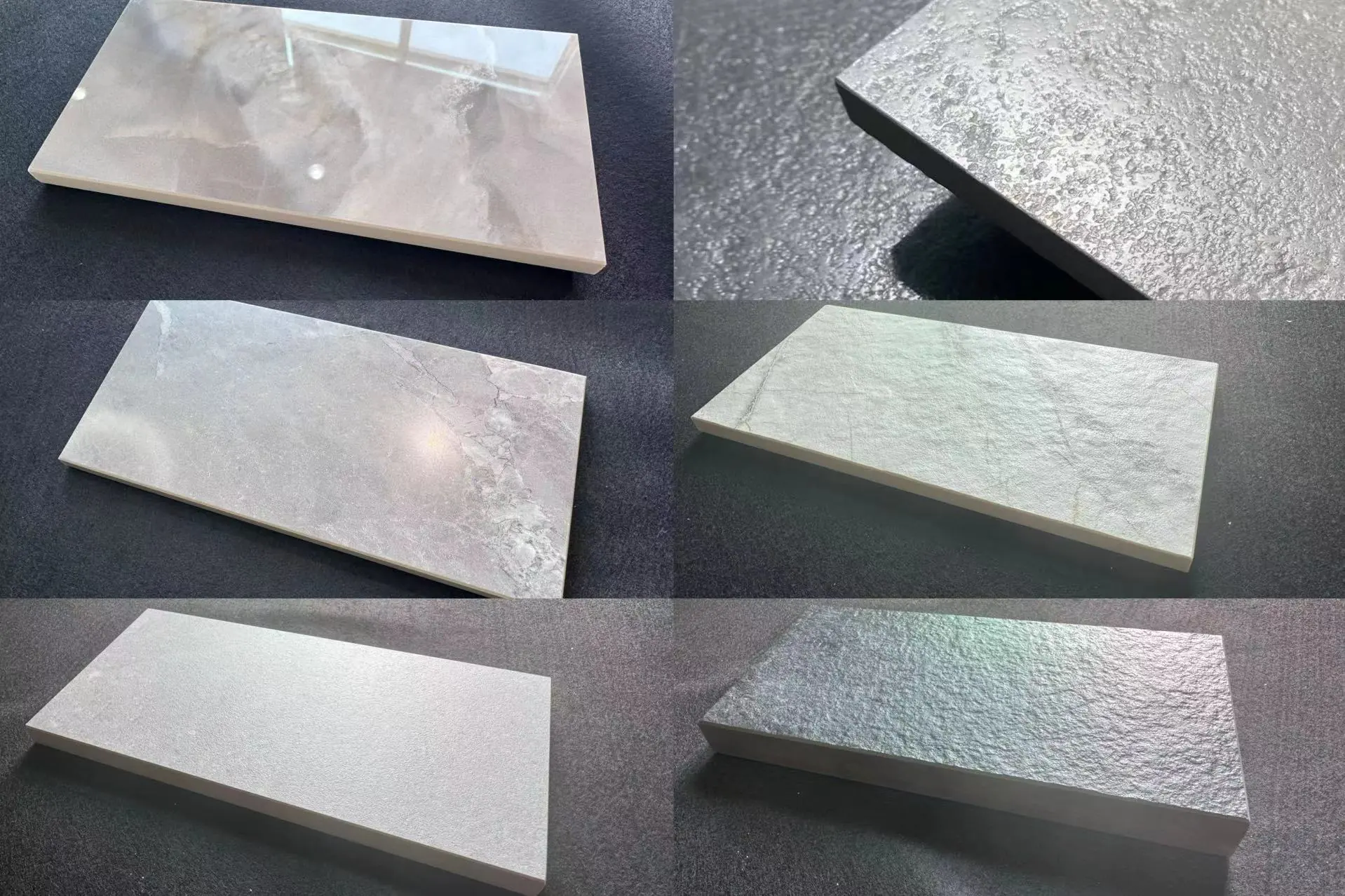

Surface & Finish

- Polished / gloss and matt / silk are the most classic and simple surface finishes. They offer the most competitive price and are the most popular worldwide.

- Dry-granule, carved matt, sugar, leather need special raw materials and extra processing steps. These raise the cost.

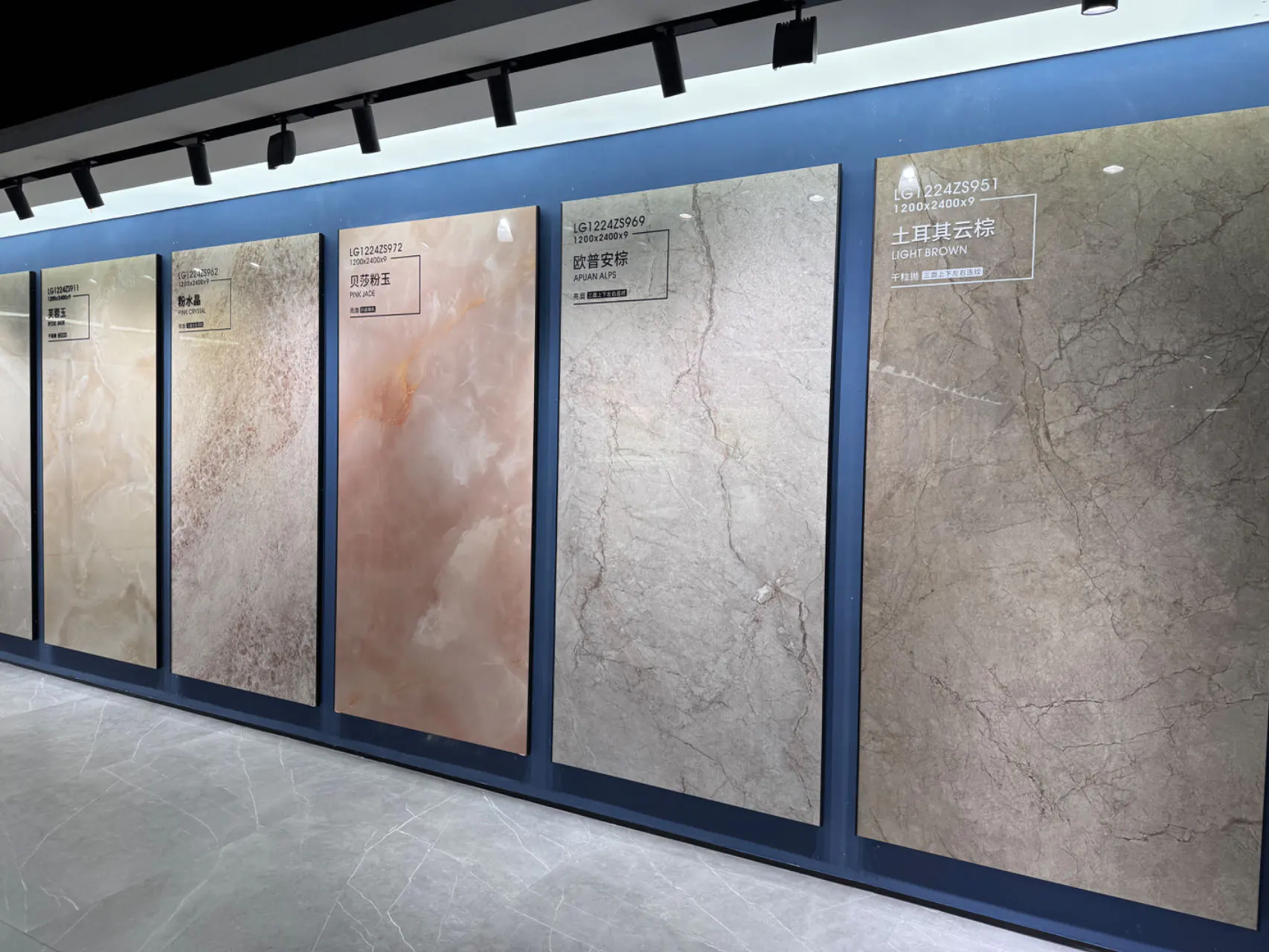

Design & Color

- White, light yellow, and grey tones are usually cheaper. Darker or bright colors such as red, blue, or purple are more expensive.

- Plain whites and greys are stable and low risk.

- Deep colors, book-match sets, and dramatic veins need tighter control and more ink. Price moves up.

Quality Grade & Certification

- Premium grade with CE, ISO 10545 testing and narrow tone control trades at a premium.

- Rework rate and shade sorting also affect cost.

Customization

- Cut-to-size, pre-mitre, edge polish, CNC drilling, logos, anti-slip ratings add labor and machine time.

- Private label packaging and printed cartons add MOQs and print fees.

If you want fast options with stable quality and custom logos, you can reach Miller at miller@kingsuntile.com.

Installation Costs & Total Landed Cost Estimation

Landed Cost Formula (per m²)

Landed Cost = FOB Unit Price + Ocean & Insurance + Origin & Destination Charges + Duty/Tax + Inland Freight + Pallet/Crate + Loss/Waste

Simple Example

Goal: Estimate landed and installed cost for 1600×3200×12 mm slabs into a major SEA port.

- FOB unit price: USD 13.25 per m²

- Ocean & insurance (FCL, spread over net m²): assume USD 2.00 per m²

- Origin & destination fees (THC, docs, devanning, spread): assume USD 1.20 per m²

- Duty/Tax: assume 5% on CIF → about USD 0.85 per m²

- Inland to warehouse: assume USD 0.90 per m²

- Crating & protection: assume USD 0.40 per m²

- Operational loss/waste (2%): \~USD 0.36 per m²

Estimated landed: USD 18.96 per m² (≈ USD 1.76 per sq ft)

Installed Cost Notes

- Fabrication: edge work, cut-outs, mitres, and sink holes vary by shop.

- Adhesives & trims: add a small but real cost per m².

- Labor: benches and façades need skilled teams and lifting gear.

- Wastage: layouts with book-match or large off-cuts need extra allowance.

Many contractors in SEA quote installed benchtops based on a per-linear-meter rate, not per m². Your final installed figure depends on local labor rates and the number of cut-outs and mitres.

Conclusion

Sintered stone now comes in wide sizes, multiple thicknesses, and many finishes. Production in China scales fast and keeps prices competitive. Buyers can expect stable quality, flexible custom options, and faster lead times. You can ask Kingsun for updated prices and a ready-to-send catalog: miller@kingsuntile.com · www.kingsuntile.com.

-

Explore the full range of Kingsun’s sintered stone products — discover key advantages, available sizes, surface finishes, packaging, and shipping options. ↩

-

Want to know what sintered stone really is? Learn about its composition, manufacturing process, and why it’s becoming a leading choice for architects and designers worldwide. ↩