When choosing tiles, it's natural to ask: what's better, porcelain or ceramic tile? The answer isn’t one-size-fits-all – each has its strengths depending on your project’s needs. Both porcelain and ceramic tiles are types of fired clay products, but subtle differences in their materials and manufacturing give them distinct properties. In this guide, we’ll break down how each tile is made, their performance in real-world conditions, design capabilities, cost factors, and finally which type of tile best fits various projects. Whether you’re a homeowner or a construction industry professional, understanding these differences will help you make an informed decision.

Core Material Differences: How Porcelain and Ceramic Tiles Are Made

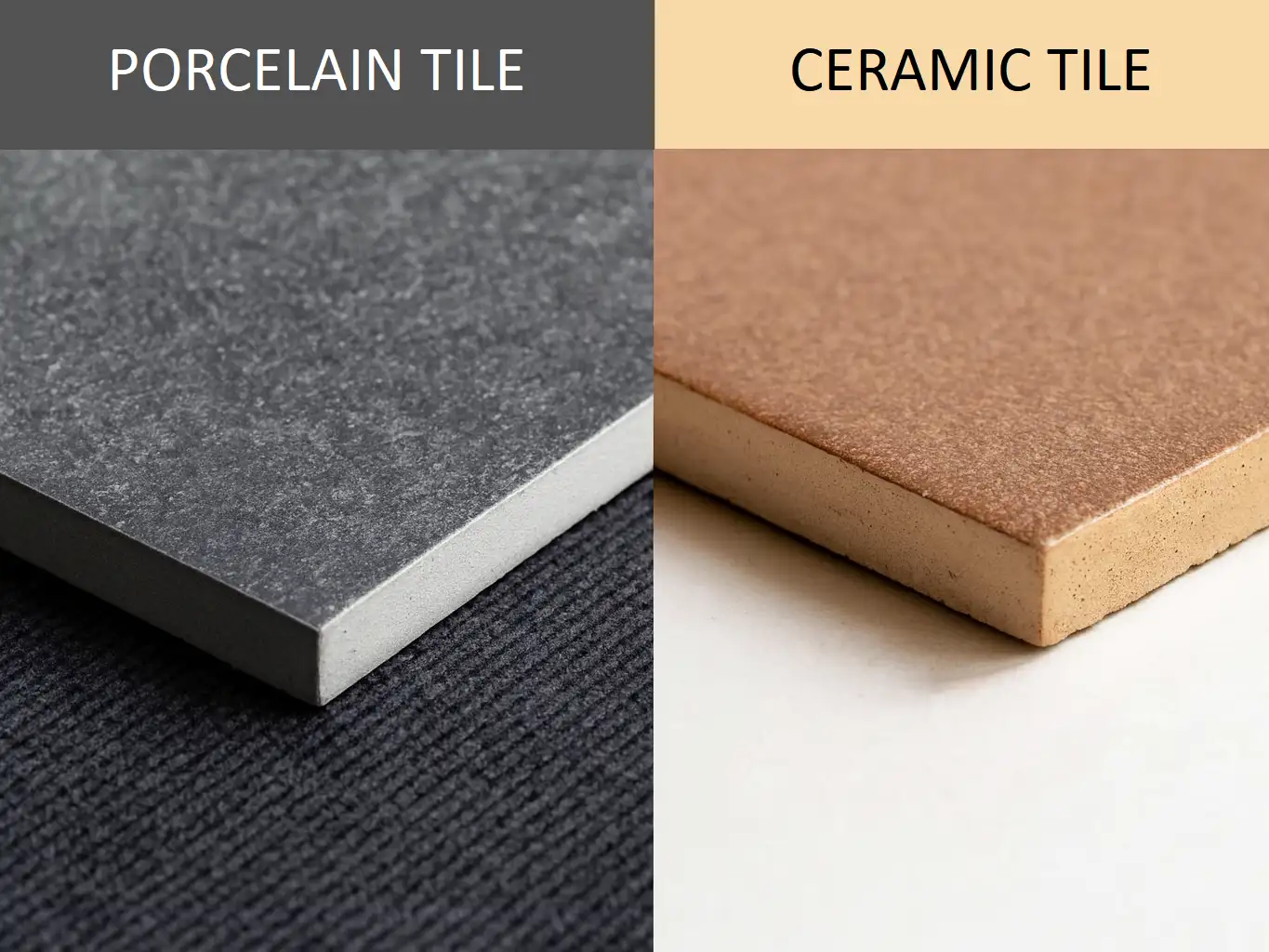

Porcelain and ceramic tiles share a similar origin – both start as clay shaped and hardened by firing in a kiln. The key differences lie in the clay composition and firing process. Porcelain tile is made from a fine-grained, highly refined clay (often with added feldspar) that is pressed under high pressure and fired at extremely high temperatures (around 1,200–1,350°C or 2,200–2,500°F). This process vitrifies the tile, yielding an extremely dense, hard body with very low porosity.

Ceramic tile, on the other hand, uses less refined clay (often red or brown in color) and is fired at lower temperatures (typically 1,000–1,200°C). As a result, ceramic tiles are slightly more porous and softer than porcelain. The water absorption rate1 is a telltale indicator: porcelain is defined by having <0.5% water absorption, classifying it as impervious, whereas standard ceramic tiles often have around 3–7% water absorption (semi-vitreous to non-vitreous). This means porcelain’s body is essentially waterproof (and often frost-proof), while ceramic’s body is more porous (although a surface glaze usually provides water resistance in use).

These material differences also lead to practical implications. Porcelain’s higher density makes it harder and heavier than ceramic. It has superior inherent strength and is highly scratch- and chip-resistant due to its hardness and high feldspar content. Ceramic tiles are still plenty strong for most interior uses, but they are a bit softer and easier to cut or drill into. In fact, installers find that cutting porcelain requires special tools (like a diamond wet saw) because of its hardness, whereas ceramic is easier to cut with standard tile cutters.

Porcelain tiles can be unglazed (often with through-body color) or glazed just like ceramic; if unglazed, a porcelain tile is the same color throughout, so a chip is less noticeable. Ceramic tiles are almost always glazed on top of a different-colored body – if the tile chips, the clay color beneath may show.

Summary table: Core material characteristics

| Material Aspect | Porcelain Tile | Ceramic Tile |

|---|---|---|

| Clay Composition | Fine kaolin clay with added minerals (e.g., feldspar); highly refined. | Less refined clay (often red/brown), may include impurities. |

| Firing Temperature | ~1,200–1,350°C (2,200–2,500°F). | ~1,000–1,200°C. |

| Density & Porosity | Very dense/vitrified; water absorption <0.5% (impervious). | More porous; typically 3–7% absorption; glaze adds surface water resistance. |

| Hardness & Strength | Extremely hard/durable; high scratch and chip resistance. | Hard but slightly softer; may chip/crack sooner under heavy pressure. |

| Color Body | Often through-body (if unglazed); chips less noticeable. | Usually glazed over different-colored body; chips reveal interior clay. |

| Workability (Cutting) | Difficult; diamond blades/pro tools recommended. | Easier; more DIY-friendly with standard tile tools. |

Real-World Performance: Durability, Water Resistance & Maintenance

Durability & traffic: Porcelain tile generally outperforms ceramic in durability and water resistance, while both are relatively easy to maintain. Porcelain’s dense, hard body makes it ideal for high-traffic and demanding environments (including many commercial settings2). Ceramic tile is durable in its own right but better suited for light to moderate traffic (e.g., residential floors with normal use or wall applications).

Water & moisture: Porcelain is highly water-resistant – its <0.5% absorption means water rarely penetrates the tile body. It handles bathrooms, showers, kitchens, pools/spas, and many exterior settings (including freeze–thaw) when properly installed. Ceramic tiles, with higher absorption, are typically not recommended for outdoor use or continuously wet environments unless specifically rated. For indoor wet areas, glazed ceramic can perform well when properly grouted/sealed.

Maintenance: Both types are low-maintenance. Glazed surfaces are non-porous and easy to clean with basic household cleaners; tile surfaces typically don’t require sealing (grout lines may). Porcelain’s ultra-low porosity offers extra resistance to staining and odors. One practical difference: porcelain’s hardness can make installation more challenging and potentially increase labor cost.

Summary table: Performance comparison

| Performance Factor | Porcelain Tile | Ceramic Tile |

|---|---|---|

| Durability & Wear | Excellent for heavy use/high traffic; hard, dense body resists chips and scratches. | Good for normal use; better for low–mid traffic; may show wear/chip sooner in very high-traffic areas. |

| Water Resistance | Highly water-resistant; often impervious (<0.5%); suitable for wet areas and outdoors (when installed right). | Water-resistant glaze but more porous body (often 3–7%); generally indoor-focused; avoid prolonged moisture/outdoors unless rated. |

| Maintenance Needs | Very low maintenance; resists stains/odors; tile surface usually doesn’t need sealing. | Low maintenance; glaze is easy to clean; wipe spills promptly; seal grout, address crazing or micro-cracks if any. |

| Installation Factors | Dense/heavy; cutting/drilling more challenging; pro tools advised; extremely stable once installed. | Lighter/easier to cut; DIY-friendlier; similar install techniques; large-format ceramic floors are less common. |

Design & Production Capabilities: Small-Batch Creativity vs. Large-Format Efficiency

Ceramic for artistry and small-batch: Ceramic tiles excel in small-batch, creative designs. The slightly softer, more workable body supports handmade tiles, intricate shapes, sculpted textures, and richly colored glazes. You’ll find vast variety in small formats (e.g., tiny hexagons, penny rounds, subways). Ceramic is ideal where bespoke aesthetics matter (custom backsplashes, feature walls, historic styles).

Porcelain for scale and large-format: Porcelain shines in large-format and mass-production efficiency. It can be manufactured in bigger sizes (e.g., 24×24 in or larger; even panel slabs around 3×1.5 m) for sleek, minimal-grout installations. Modern porcelain uses advanced printing/glazing to convincingly mimic stone, wood, marble, concrete, etc. It’s popular for achieving upscale looks at scale (e.g., hotels, malls). While small porcelain mosaics exist, the range of very small or unusual shapes is more limited versus ceramic. Many projects combine both: porcelain for broad floors, ceramic for accents/trim.

Cost & Supply Considerations: Balancing Price, Scale, and Lead Times

Costs: In general, porcelain costs more per square foot than standard ceramic of similar size/finish due to higher-grade materials and more intense firing. Ceramic is often the budget-friendly choice for large areas or cost-sensitive projects. However, not all ceramic is cheap: artisanal/handmade or designer ceramics can cost more than mass-produced porcelain. Typical machine-made porcelain floor tile often falls around ~$3–$10/㎡ depending on quality, while handmade ceramic could reach ~$20/㎡ (or more).

Supply & lead times: Porcelain manufacturers often produce large volumes of popular styles, so distributors/home centers commonly stock standard colors/sizes—great for consistency and quick turnarounds. Specialty ceramics may have longer lead times or limited availability; small studios may make to order (weeks to months) and glazes can vary by batch, encouraging single-lot purchasing for color consistency. For large developments or chain rollouts (B2B), porcelain’s performance plus ready supply often yields better value; for boutique/one-of-a-kind features, the extra cost/wait for special ceramics may be warranted. Consider total lifecycle value: porcelain’s durability vs. ceramic’s unique style value.

Conclusion & Buyer’s Guide: Which Tile Fits Your Projects Best?

Bottom line: Neither porcelain nor ceramic is universally “better”; the best choice depends on your project’s priorities (use conditions, traffic, water exposure, design goals, budget).

Choose Porcelain Tile if…

- You need maximum durability and versatility (high-traffic floors: busy family kitchens, hallways; retail/office floors).

- You’re working in wet or outdoor environments (bathrooms, showers, pools, patios; frost resistance with proper install).

- You want large-format tiles and minimal grout lines that install flat and stay stable.

- You’re sourcing for commercial or large-scale builds (hotel lobbies, exterior cladding) where longevity and availability matter.

- Style tip: Modern porcelain offers extensive looks (wood-, marble-, stone-, or concrete-effect) without sacrificing performance.

Choose Ceramic Tile if…

- Your project is decorative, indoor, or has budget constraints.

- You want unique shapes/colors3 and artisanal character (mosaics, hand-painted accents, feature walls).

- You prefer lighter/easier cutting for DIY or wall applications.

- You’re tiling indoor, non-freezing spaces with moderate foot traffic and want cost-effective coverage.

- When used appropriately, ceramic can last for decades and deliver standout visual appeal.

In many cases, a combination works best (e.g., porcelain on floors, ceramic on walls). Use each material’s strengths to your advantage and you’ll enjoy a beautiful, durable surface for years.

-

Understand how water absorption rates influence tile durability and suitability for different environments. ↩

-

Discover the most suitable tiles for high-traffic commercial environments, balancing durability and style. ↩

-

Find inspiration for selecting tiles that add character and uniqueness to your spaces. ↩