Floor tiles are one of the most widely used materials in modern architecture and interior design. With so many types, sizes, and finishes available, choosing the right tile can feel overwhelming. This guide breaks down everything you need to know about floor tiles—from basic definitions to material types, quality checks, and sourcing tips. Whether you're designing a home or managing a commercial project, this article will help you make smart, confident tile decisions.

What is a floor tile?

A floor tile is a flat piece of hard material (usually ceramic or porcelain) used to cover floors. Floor tiles are made to be durable and handle foot traffic, coming in various sizes and finishes. China is one of the largest producers of floor tiles and follows strict quality standards like ISO 10545,EN 14411, GB/T 4100. This means Chinese floor tiles meet international definitions for water absorption, strength, and dimensions.

What tile is best for floors? (Choose by room, traffic & budget)

Choosing the best floor tile depends on where it will be used, how much wear it will see, and your budget. Consider these guidelines:

- Room Type: For wet areas like bathrooms, choose tiles with anti-slip surfaces (e.g. matte ceramic mosaics or textured porcelain). Living rooms and bedrooms (moderate traffic) can use polished or matte porcelain for an elegant look. Kitchens benefit from easy-to-clean glazed tiles (porcelain or ceramic) that resist stains.

- Foot Traffic: High-traffic zones (hallways, retail stores) need very durable tiles like full-body porcelain with high wear ratings. Low-traffic rooms (guest rooms or low-use areas) can use standard ceramic tiles, which are more budget-friendly. Always match the tile’s strength (PEI rating) to the expected foot traffic.

- Budget: Porcelain tiles generally cost more but offer top durability and low maintenance. If you have a tight budget, good-quality ceramic tiles can work for light to medium traffic areas without breaking the bank. It’s about balancing upfront cost with how long the tile will last.

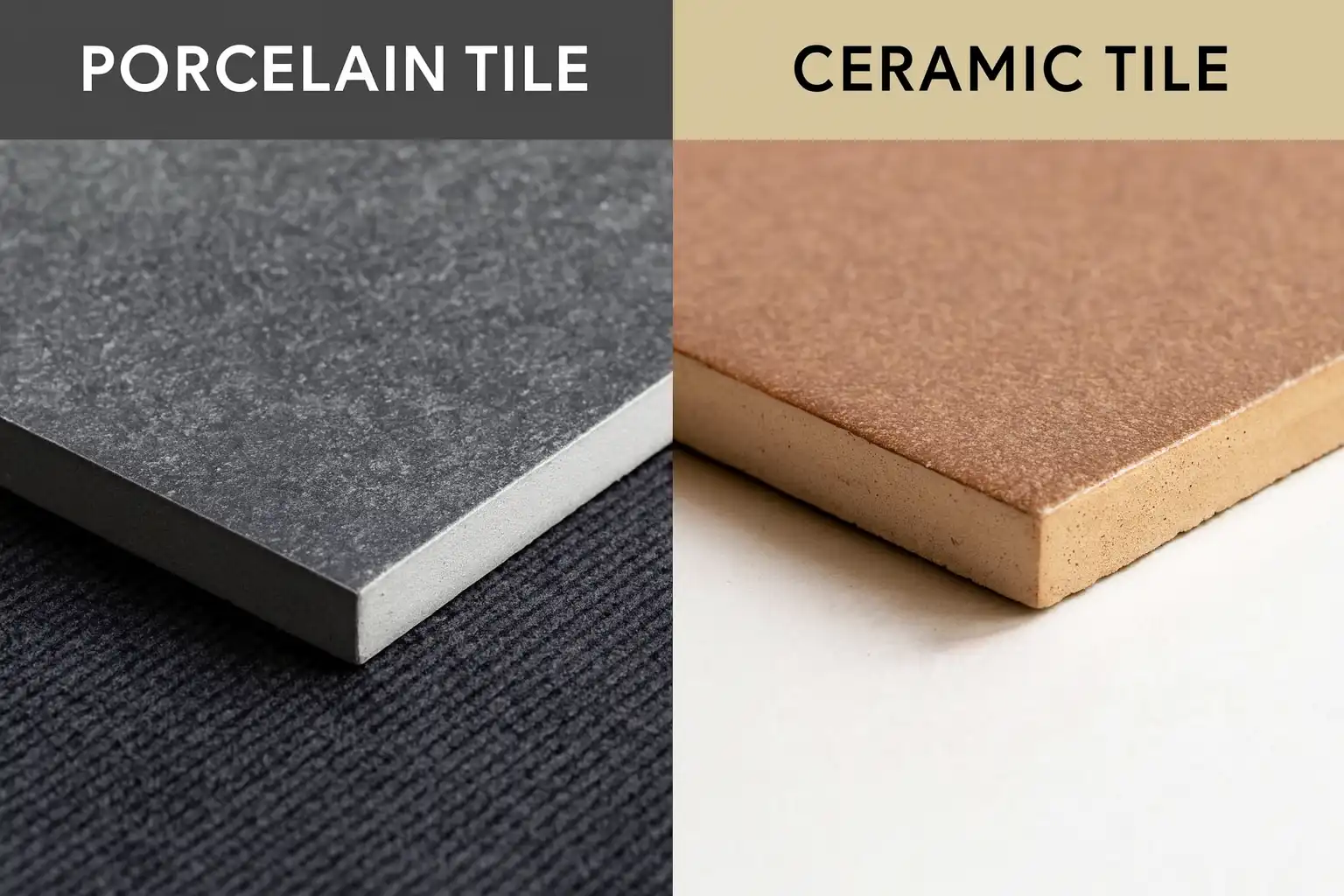

Porcelain vs Ceramic: Which is better for flooring?

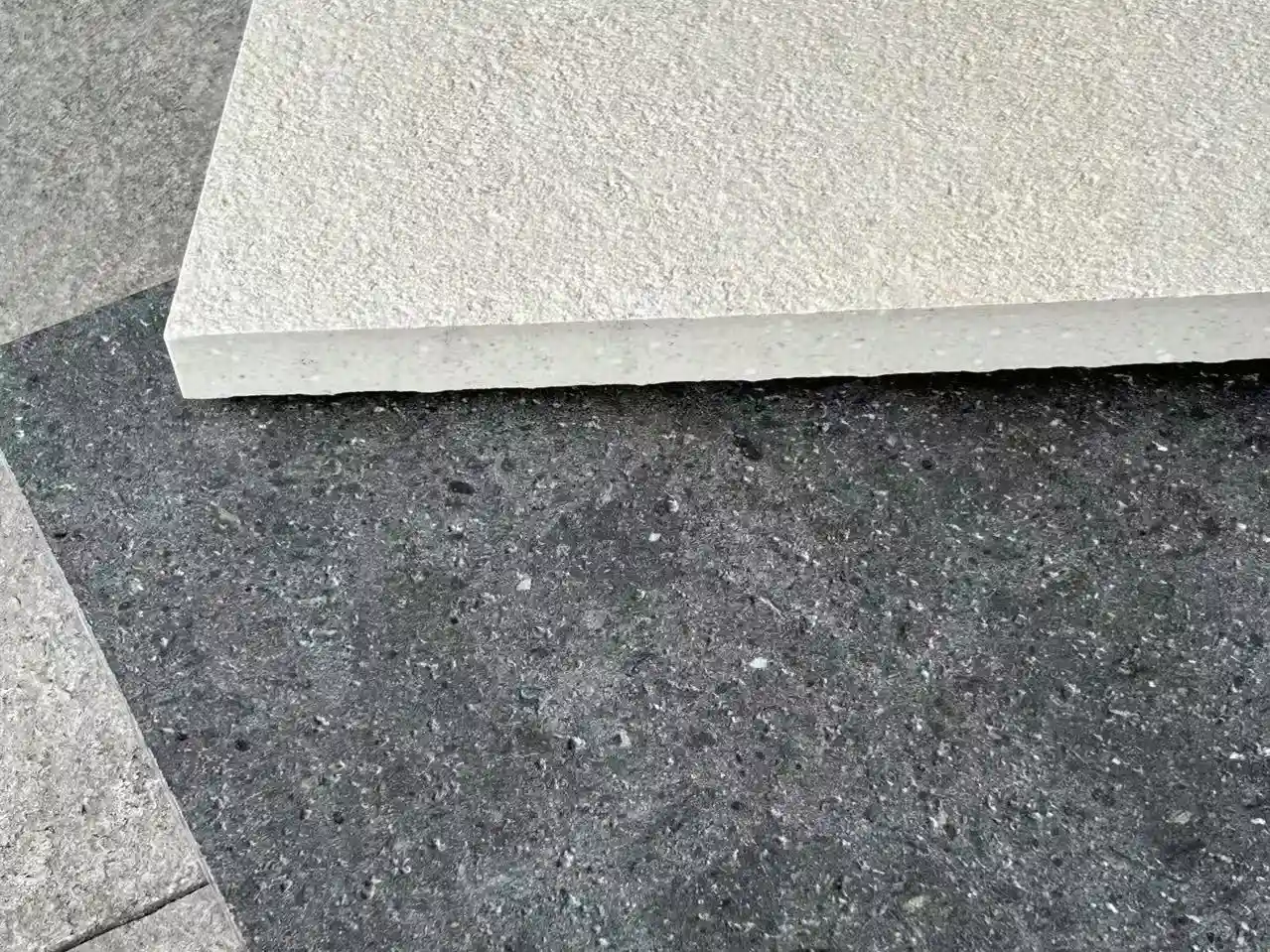

Porcelain tiles are denser and have extremely low water absorption (under 0.5% ). They are fired at higher temperatures, which makes them harder and ideal for heavy use and moisture-prone areas. Ceramic tiles are slightly more porous (often 1–3% water absorption) and softer , so they work well for light to moderate traffic floors but may wear out faster under heavy duty use. In general, porcelain is considered better for most flooring projects because it’s more durable and water-resistant.

(For a detailed comparison, see our Porcelain vs Ceramic Tile guide.)

👉 Blog:What’s Better? Porcelain or Ceramic Tile

What are the different types of floor tiles?

Floor tiles come in several material types, each with unique qualities. Here are six common types:

-

Porcelain Tile: A type of ceramic tile fired at very high temperature. Porcelain tiles are extremely hard and impervious (water absorption ≤ 0.5%), making them excellent for floors, including outdoor and wet areas. They’re known for durability and come in many styles (marble-look, wood-look, etc.).

-

Ceramic Tile: Traditional ceramic tiles (often made with red or brown clay) are fired at lower temperatures than porcelain. They are a bit more porous and usually glazed on top for color.

Ceramic tiles are ideal for indoor floors with moderate traffic, offering a cost-effective and easy-tocut option for homes. -

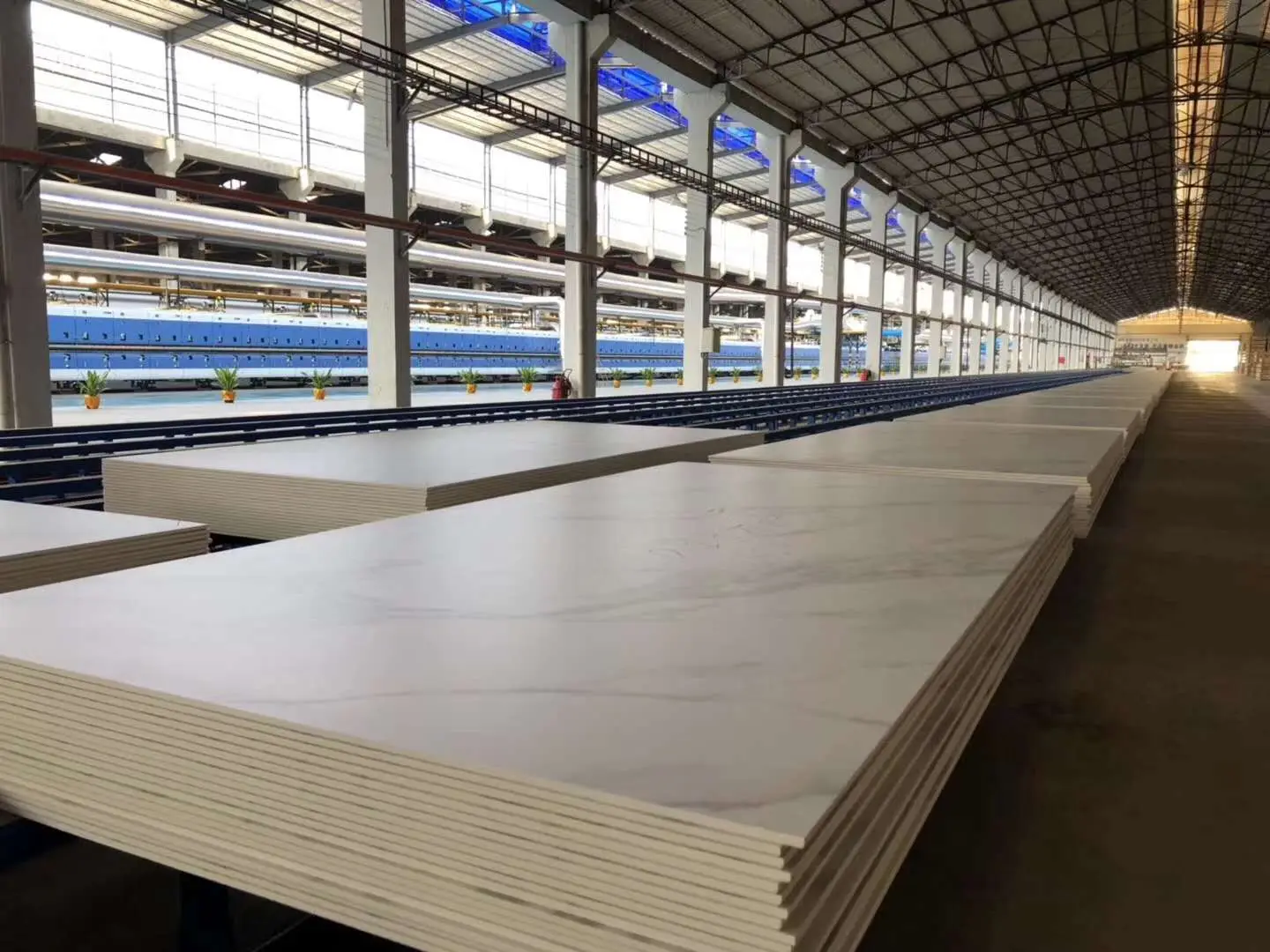

Sintered Stone Tile: An ultra-compact large-format tile, essentially a porcelain slab made under very high pressure and heat. Sintered stone tiles have near-zero porosity and exceptional strength. They are used in upscale flooring, walls, and countertops, providing the look of natural stone with higher performance.

-

Mosaic Tile: Mosaics are sheets of many small tiles (ceramic, porcelain, glass, or stone) usually 2x2 inches or smaller. They are often used for shower floors, backsplashes, and decorative accents. Because of the many grout lines, mosaic floor tiles offer good slip resistance in wet areas like pools and bathrooms.

-

Terrazzo Tile: Terrazzo tiles are made of chips of marble, granite, or other aggregates embedded in cement or resin and polished smooth. They have a speckled, confetti-like appearance. Terrazzo is very strong and is commonly used in commercial floors (hotel lobbies, airports) for its unique style and long wear life.

-

Metal Tile: Metal tiles can be made entirely of metal (like steel or copper) or be ceramic tiles with metallic glazes. They are usually used as decorative insets or accents rather than whole floors. When used on a floor, metal-look tiles add an industrial or modern accent, but they’re typically limited to low traffic or feature areas due to scratching concerns.

(For a full breakdown of each type, see the complete floor tile types guide.)

👉 Blog:A Comprehensive Guide to Floor Tile Types: Materials, Finishes, and Patterns

Common Types & Uses (Living room, commercial, outdoor & wet areas)

Different spaces call for different floor tile choices. Here’s a quick use-case guide by area:

- Living Rooms: These are moderate-traffic areas, so you can use either porcelain or ceramic tiles. Many homeowners prefer larger tiles (e.g. 600×600 mm polished porcelain) in living rooms to create a spacious, seamless look. Choose a finish that suits your style – polished for a shiny luxe feel, or matte for a cozy, non-slip surface.

- High-Traffic Commercial: For commercial floors like shops, restaurants or office lobbies, go with heavy-duty porcelain tiles. Look for tiles with a high PEI wear rating (PEI 4 or 5) that can handle constant foot traffic. A matte or textured finish is smart for safety, and darker or patterned designs help conceal dirt in busy areas.

- Outdoor Areas: Patios, walkways, or balconies need tiles that withstand weather. Porcelain tiles rated for outdoor use are ideal since they won’t absorb much water (preventing cracks in freezethaw cycles). Use textured or structured tiles (often labeled as outdoor or anti-slip porcelain) so the surface isn’t slippery when wet. These tiles are often a bit thicker (20mm porcelain pavers or similar) for added strength.

- Wet Areas (Bathrooms & Pools): In bathrooms, showers, or around pools, slip resistance is the top concern. Small-format tiles like mosaics or anti-slip porcelain are commonly used on floors here. The extra grout lines in mosaics give better traction, or you can use porcelain with an antislip rating (e.g. an R11 matte finish) for safety. Always choose tiles with nearly zero water absorption (porcelain) in very wet zones to prevent any water damage.

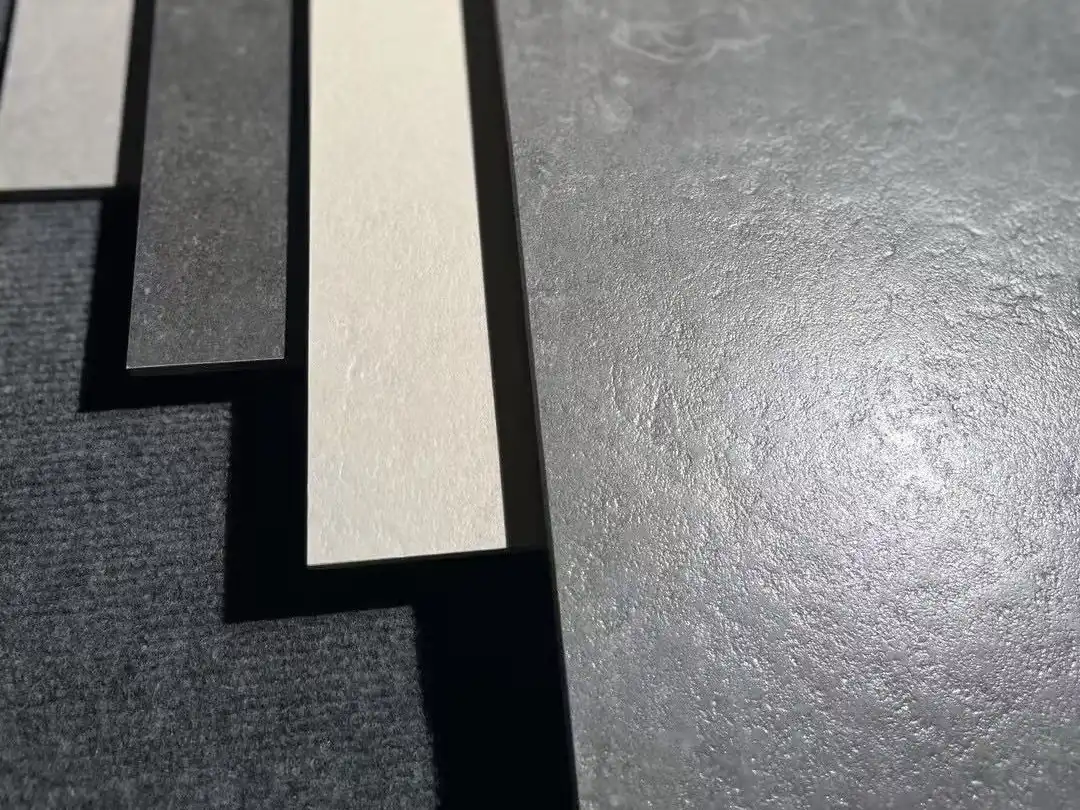

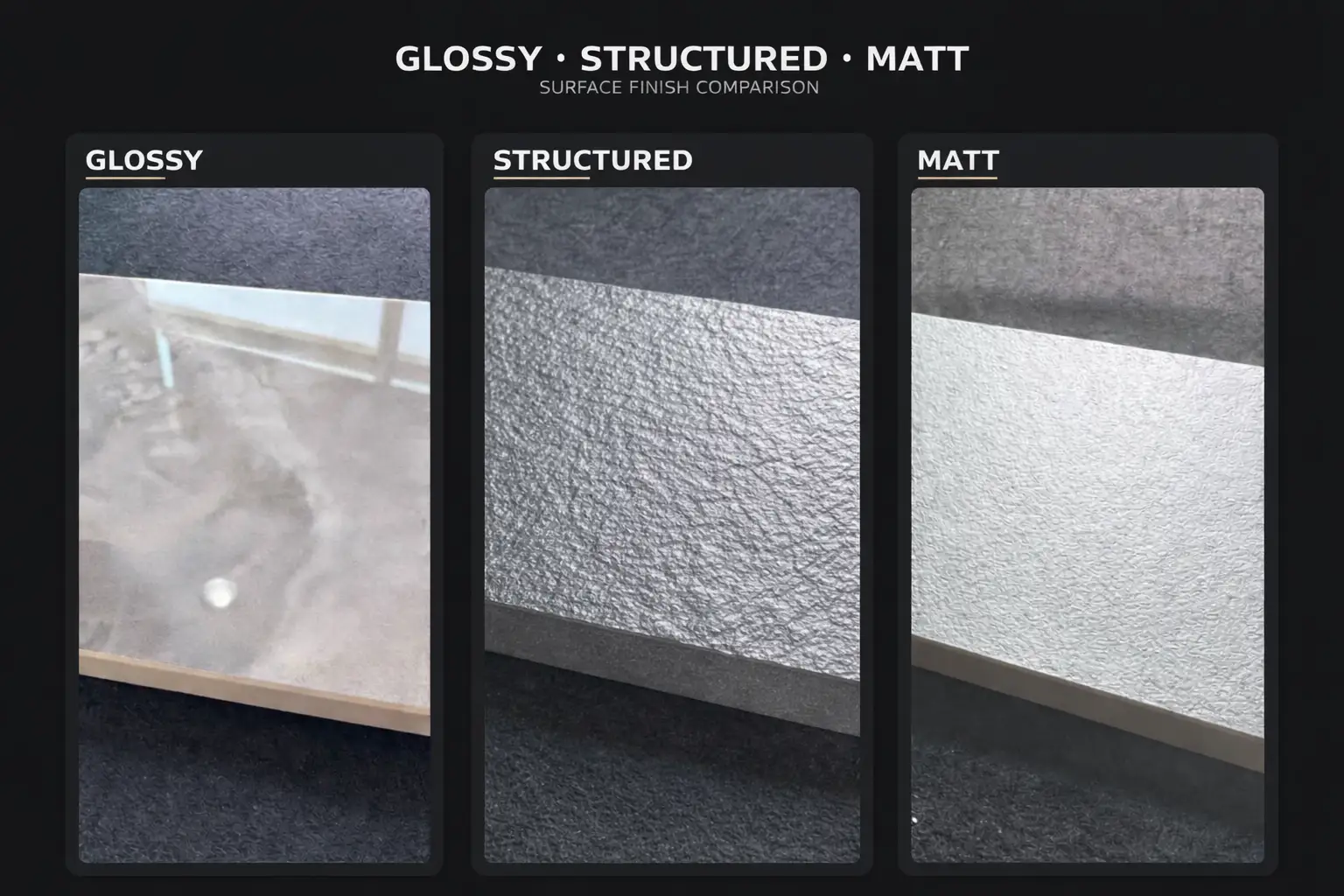

Popular Styles & Finishes (Polished, Matte, Structured/Anti-slip)

Floor tiles not only come in different materials, but also various surface finishes that affect their look and feel:

- Polished: Polished tiles have a shiny, mirror-like surface created by polishing the tile face. They often start as a porcelain tile that’s ground and buffed to a high gloss. Polished tiles look luxurious and can make a room feel larger by reflecting light. Keep in mind they can be slippery when wet and might show smudges or dirt more easily, so they’re best in dry, high-visibility areas (like living rooms or hotel lobbies) where a premium look is desired.

- Matte: Matte tiles have a non-reflective, satin or flat finish. They don’t have glare, giving a more natural and understated appearance. Matte floor tiles provide better grip than polished because the surface isn’t as slick. They also tend to hide scratches or dried water drops better, making them a practical choice for kitchens, hallways, and bathrooms where you want a stylish but slipresistant surface.

- Structured / Anti-slip: These tiles have a textured surface with bumps or grooves to enhance traction. Often called rustic tiles in China (for their rough, stone-like look), they provide a matte, aged finish with high slip resistance. Structured anti-slip tiles are perfect for outdoor patios, pool decks, or bathroom floors – anywhere you need extra grip underfoot. They usually carry an R11 or higher slip rating, meaning they’ve been tested to perform well in wet conditions.

(For more on various tile finishes and styles, see our tile finishes guide.)

👉 Blog:10 Types of Tile Finishes: Glossy, Matte, Honed & More

What is the most popular tile size?

The most popular floor tile size internationally today is around 600×600 mm (24×24 inches). This size is widely used because it’s large enough to look modern and cover area with fewer grout lines, yet manageable for installation. Many home and commercial projects use 600×600 mm porcelain tiles for living rooms, malls, and open spaces. Another common size is 600×1200 mm (approximately 24×48 inches), which gives a stretched, plank-like appearance that’s very popular in contemporary designs. It’s often used on floors and even walls to create a seamless, high-end look.

In recent years, large format tiles have become a major trend. Manufacturers in China now produce huge porcelain slabs of 900×1800 mm, 1000x1000mm, 1200x1200mm, 1200×2400 mm, and even up to 1600×3200 mm panels. These large tiles greatly reduce the number of grout lines, resulting in a clean, luxurious expanse on the floor or wall. Designers love large slabs for upscale projects like hotel lobbies, big living areas, and feature walls because they create a dramatic, continuous surface. However, keep in mind that as tile size grows, so does the challenge in handling and installing them. Large tiles require very level subfloors and skilled installers with the right equipment. They also weigh more and take up more room in shipping. Despite these considerations, sizes like 900×1800 mm and above are increasingly used for their stunning visual impact and the modern, seamless style they bring to spaces.

Large Format & Big Slab Tiles: Sizes, applications & key considerations

“Large format” tiles generally refer to any tile significantly bigger than the traditional 600×600 mm. Common big slab sizes include 900×1800mm, 1000x1000mm, 1200x1200mm, 1200×2400 mm, and up to the enormous 1600×3200mm sintered stone panels . These big slabs can cover a shower wall or floor almost entirely in one piece, creating an ultra-seamless look that’s very high-end. Applications of large format tiles range from living room floors (fewer joints make the space look bigger) to expansive hotel lobbies, and from feature walls to kitchen countertops (especially when using 6mm or 12mm thick porcelain slabs as a “sintered stone” counter material).

When using large and slab tiles, there are a few key considerations:

- Installation: Big tiles require expert installation. The tiles are heavy and not flexible, so the substrate (floor or wall) must be extremely level to avoid hollow spots. Tilers use special largeformat tile trowels, leveling clips, and sometimes suction cup lifters to handle these slabs. It often takes multiple people to safely lay a 3-meter slab.

- Handling & Shipping: Due to their size, slabs need careful handling. Factories pack large tiles with extra protection (often each slab is packed upright with foam sheets and wood supports). Shipping might require custom crates or A-frame racks inside the container to keep slabs secure. This adds a bit of cost and complexity in logistics.

- Cutting & Equipment: Cutting large porcelain slabs for edges, holes, or fitting requires specialized tools (like rail saws or waterjet cutters). Installers may need to cut slabs on-site for precise fits, so ensure they have the capability to do so.

- Uses: Large format tiles excel in open areas where you want an uninterrupted look – for instance, an office lobby with 1.2×1.2 m tiles, or a master bathroom with floor-to-ceiling slab walls. They are also used for “big slab” countertops and tables, as they imitate marble or stone slabs but with higher stain resistance. Always match the slab thickness to the use (e.g. 10-12 mm thick for flooring durability, or thin 6 mm slabs for cladding walls).

In summary, big slabs offer a striking, modern aesthetic with minimal seams. You just need to plan for their special handling and installation needs, and work with experienced professionals. The result can be well worth it in high-end projects.

Tile Quality Checklist: Water absorption, PEI wear rating & slip resistance (R rating)

When evaluating floor tile quality, importers and distributors should check a few key technical factors:

- Water Absorption: This tells you how much water the tile material can absorb, affecting where it can be used. Low absorption is better for flooring (especially in wet areas). Porcelain tiles are classified as having ≤0.5% water absorption (essentially waterproof), while standard ceramic tiles might have 3–10% absorption. For floors, especially bathrooms or outdoors, aim for tiles with <0.5% (impervious) so they won’t soak up moisture. Lower absorption also generally means a denser, stronger tile.

- PEI Wear Rating: The PEI rating (developed by the Porcelain Enamel Institute) measures the glaze hardness and wear resistance of a tile. It’s usually rated from PEI 1 to PEI 5. For floor tiles: PEI 3 is rated for normal residential foot traffic (bedrooms, living areas), PEI 4 for heavier traffic (kitchens, corridors, small commercial), and PEI 5 for very high traffic or commercial use (shopping centers, public spaces). Always choose a tile with an appropriate PEI rating for the intended area so it doesn’t wear out its pattern or finish prematurely.

- Slip Resistance (R Rating): Many floor tiles, especially from Europe or China, come with an “R” slip resistance rating. This R9–R13 scale indicates how slip-resistant the tile is, with R9 being the lowest friction and R13 the highest . For example, R9 tiles are smooth and only suitable for dry areas (living rooms, etc.), R10 and R11 are often used in kitchens or bathrooms (moderate slip resistance), and R12–R13 tiles have very rough/textured surfaces suited for outdoors, pool decks, or commercial kitchens where floors may be wet or greasy. When sourcing tiles, check the R rating if provided: an R11 is a good target for bathroom or patio flooring to ensure safety when the tiles are wet.

By checking these factors – water absorption to gauge density, PEI for surface durability, and R rating for slip safety – you can judge if a given tile is appropriate for your project or market. Always request the technical specifications from the supplier; reputable Chinese manufacturers will have test data for water absorption and wear (and sometimes European CE or ASTM slip test results) to back up their product quality.

Which country is best for tiles? (Italy vs Spain vs China vs India)

Different countries have different strengths in tile production:

- Italy: Italian tiles are famous for their luxury designs and top-notch quality. Italy has a long history of ceramics and is known for trend-setting styles and very refined finishes. However, Italian tiles are very expensive and often come with a premium for the brand and design. They’re great for high-end projects, but you pay a lot for that “Made in Italy” label.

- Spain: Spanish tiles are also considered high quality and have excellent designs, often a bit more affordable than Italian. Spain produces a wide range of styles and is strong in decorative tiles and innovative textures. Like Italy, Spanish factories are known for quality control. Cost is still on the higher side compared to the rest of the world, but slightly less than Italian on average.

- China: China is the world’s largest tile producer and offers the best balance of quality, variety, and price. In the past, some thought Chinese tiles were lower quality, but today many Chinese manufacturers meet or exceed European standards . China’s factories use modern Italian and Spanish machinery and produce everything from basic economical tiles to premium large-format slabs. You can source very affordable tiles for budget projects or high-end tiles that rival Italian brands. The scale and competition in China also drive costs down – you generally get much better price per quality unit. Overall, Chinese tiles provide an unparalleled mix of decent quality, huge design selection, and competitive pricing .

- India: Indian tiles are typically positioned as a budget option. India has a growing tile industry with large volume output and very low prices. You can find some good tiles from India, but quality consistency can be an issue (some batches might have more variation). Design-wise, India offers fewer upscale designs compared to Italy/Spain, focusing more on mass-market styles. Indian tiles can be a great low-cost choice for big projects where budget is the main concern, but you may need to double-check quality specs and certifications.

Conclusion: Italy and Spain make excellent tiles with top design, but at a high cost; India offers low prices but with some trade-off in refinement and consistency. China hits the sweet spot – you can get quality that approaches European brands while paying a fraction of the price, plus a vast selection of designs and formats. For most international distributors and projects, China is the most balanced choice for sourcing tiles.

Which Chinese brands are good for floor tile?

China has hundreds of tile brands, but a few stand out for quality and reputation. Notable top brands include Dongpeng and New Pearl (Guanzhu) – these are giants producing tens of millions of square meters of tiles annually and known worldwide . They offer everything from polished porcelains to rustic tiles and have a strong track record. Monalisa is another leading brand, famous for innovation in large porcelain slabs and high-end designs (often considered China’s answer to Italy’s luxury brands)). Nabel and Marco Polo are also highly respected, with Nabel known for technical quality and Marco Polo for its designs and branding in China.

For value-oriented buyers, newer manufacturers like Kingsun are gaining attention. Kingsun1 (based in Foshan) is a flexible, export-focused factory known for delivering good quality tiles at very competitive prices . They even offer customized production and OEM branding, which is great for distributors who want their own tile line. In summary, if you’re sourcing floor tiles from China, you can consider big names like Dongpeng, New Pearl, Monalisa for proven quality, or look at reliable mid-sized companies like Kingsun that offer great value and service to international buyers.

Why Foshan is a global sourcing hub for floor tiles

Foshan, a city in Guangdong province, is often called the “Ceramics Capital” of China – and for good reason . This region is the heart of China’s tile industry, with hundreds of tile factories, large-scale showrooms, and supporting businesses all concentrated in one area. For a buyer, this clustering is a huge advantage: you can visit dozens of factories and tile exhibits within a short drive, allowing you to see a vast range of products and negotiate with multiple suppliers in one trip .

The supply chain in Foshan is extremely well-developed. Tile manufacturers here benefit from local sources of raw materials (clay, glazes, pigments) and a network of equipment suppliers (many use imported Italian machinery). Because everyone’s in one place, innovation spreads quickly and you can find every type of tile – polished porcelain, glazed ceramic, rustic matt tiles, mosaics, large sintered stone slabs – all in Foshan’s product catalog. This means as an importer you have one-stop access to any style or technology of floor tile you need.

Foshan is also geared toward export and international business. Many factories have English-speaking sales teams, export licenses, and experience with global shipping. They regularly attend trade fairs (the Canton Fair in Guangzhou and the Ceramic China expo in Foshan) to showcase to overseas buyers. Logistic-wise, Foshan is near major ports (Guangzhou, Shenzhen), so arranging container shipments is straightforward. Most suppliers can quote FOB Foshan or FOB Guangzhou port easily, and there are plenty of freight forwarders in the area who specialize in handling tile logistics.

Additionally, Foshan has facilities like China Ceramics City (a massive tile showroom mall) and an international ceramics exhibition center, which make it convenient for buyers to see a broad selection of offerings in one place. Supporting services like packaging companies (for custom crates or pallets), quality inspection agencies, and export brokers are all readily available in the Foshan area.

All these factors make Foshan unparalleled as a global hub for sourcing floor tiles. You get the widest selection, efficient comparison shopping, and a whole infrastructure built around ceramic tile export. It’s no surprise that importers from around the world flock to Foshan when they want to source tiles – the combination of variety, cost, and convenience is hard to beat.

How to import floor tiles from China: Step-by-step wholesale process

Importing tiles from China may seem complex, but it can be broken down into clear steps. Below is a step-by-step wholesale process:

- Supplier Research: Identify and evaluate potential tile suppliers in China. You can search on B2B platforms (like Alibaba, Made-in-China) or visit trade fairs (e.g. Canton Fair, Ceramic Expo in Foshan). Look for suppliers with good reviews, export experience, and tiles that match your requirements (porcelain vs ceramic, designs, certifications). Create a shortlist of reliable manufacturers or trading companies.

- Request Samples & Quotes: Contact the shortlisted suppliers to request product catalogs and price quotes. It’s wise to ask for samples of the tiles you’re interested in – this lets you check the quality, color, and finish in person. When you get quotations, note the unit price, the MOQ (Minimum Order Quantity, usually expressed in square meters or cartons), and the incoterms (FOB, CIF, etc.). Compare prices and quality of samples to decide which supplier offers the best value.

- Place Order & Deposit: Once you’ve chosen a supplier and specific tile items, place your order. The supplier will issue a proforma invoice detailing the product, quantity, price, and terms. At this stage, you typically need to pay a 30% deposit to confirm the order and allow the factory to start production. Ensure all specifications (tile size, color, surface finish, packaging requirements) are clearly listed in the invoice or contract to avoid any confusion.

- Production & Quality Control: The factory will produce the tiles according to your order. Production time is usually a few weeks (e.g. 2–4 weeks for a full container order, depending on quantity and factory schedule). During this phase, maintain communication – you can request updates or photos of the production. It’s also a good idea to plan for quality control: you might arrange a third-party inspection or at least have the supplier send detailed photos of the finished tiles and packaging.

- Packaging & Consolidation: After production, the tiles are packed for shipment. Floor tiles are packed in cardboard cartons, then stacked on wooden pallets (and sometimes wrapped or strapped) for stability. If you ordered different designs or sizes, the supplier will consolidate them – make sure each design is clearly labeled and separated. Confirm that the packaging is exportworthy (strong cartons, corner protection, pallets or crates as needed). Well-packaged tiles will reduce breakage during transit.

- Shipping Arrangement: Next, you or the supplier will book the sea shipment. If your terms are FOB (Free On Board), you as the buyer will arrange a freight forwarder to handle shipping from the port in China to your destination. If terms are CIF (Cost, Insurance, Freight), the supplier will arrange the shipping to your destination port (and include the cost in your invoice). In either case, ensure all necessary export documents are prepared: commercial invoice, packing list, and Bill of Lading are essential, and usually a Certificate of Origin as well for customs . Ocean transit for tiles can range from ~2 weeks (Asia to Asia) to 4–6 weeks (Asia to Europe/Americas) depending on distance.

- Customs Clearance: When the tile shipment arrives at your port, you have to clear it through customs. Typically you hire a customs broker to handle this process. You’ll need to pay import duties and taxes (ceramic tiles often have an import duty, e.g. ~8-10%, but it varies by country) and any port fees. Provide your broker with the documents from the supplier to clear the goods. After paying the required duties and the shipment is released, you can arrange to pick up the container.

- Local Delivery & Receiving: Finally, transport the tiles from the port to your warehouse or project site. This may involve trucking the container to your location or unloading pallets at the port onto trucks. Once you receive the tiles, inspect the shipment. Check that the number of boxes and tile designs match what you ordered, and see if the tiles arrived in good condition (no major breakages inside the boxes). With everything verified, your imported China floor tiles are ready to stock or install.

Following these steps helps ensure a smooth import process. Good communication with your supplier and logistics partners at each stage is key to successfully importing tiles in bulk.

If you’re sourcing tiles from China, feel free to contact Miller at miller@kingsuntile.com for guidance or quotations on quality floor tiles.

Supplier Checklist for Distributors: QC, lead time, packaging, logistics & payment

When sourcing tiles in bulk, distributors should have a checklist to evaluate suppliers and manage orders. Key points to cover include Quality Control, Lead Time, Packaging, Logistics, and Payment terms:

- Quality Control (QC): Make your quality expectations clear from the start. Communicate the standards for tile size tolerance, thickness, color shade, and surface quality you require. It helps to include these specs in the purchase contract. Before shipment, inspect the goods: you can do this yourself if you’re in China or hire a third-party QC inspector to do a pre-shipment inspection2. The inspector should randomly check tiles for defects, verify correct designs and quantities, and ensure the packaging is secure. Only approve the shipment when you’re satisfied it meets your quality criteria.

- Lead Time: Always confirm the production lead time and delivery schedule in advance. A realistic production lead time for a wholesale tile order is around 15–30 days after deposit (depending on order size and the factory’s workload). Make sure the supplier can meet any critical deadlines you have. It’s wise to add a time buffer for unexpected delays (like shipping schedules or holidays). Keep in mind transit time by sea will be on top of production – for example, allow another 3–5 weeks for ocean shipping, depending on your location. Plan your inventory with these timelines so you don’t run out of stock.

- Packaging: Check how the supplier packs the tiles for export. Tiles should be packed in strong cardboard cartons, with appropriate cushioning (paper or foam between tiles). Cartons are typically then placed on wooden pallets and shrink-wrapped or banded for stability. Pallet packaging is standard and efficient for full-container loads. If you are mixing many different items or have less than a container, you might request wooden crates for extra protection (crating encloses the tiles completely and can reduce breakage for LCL shipments). Good packaging is crucial – it’s worth specifying things like “tiles must have corner protectors” or requesting photos of the packed pallets. This ensures the product arrives intact after a long sea journey.

- Logistics: Discuss and decide the shipping terms with the supplier. If you choose FOB, the supplier’s responsibility is to get the goods on board at the port; you will then handle the freight through your own forwarder. If you prefer CIF, the supplier will arrange the ocean freight and insurance to your destination port – this is more convenient for many buyers, especially if you’re not familiar with shipping, but make sure to compare costs. In either case, ensure the supplier can provide all needed documents (Bill of Lading, packing list, commercial invoice, Certificate of Origin, etc.) promptly after loading. Also, coordinate on customs or compliance documents: for example, some countries require certificates (like SASO for Saudi Arabia, CE for Europe) – confirm the supplier can supply those if needed. Lastly, plan how you’ll handle import clearance and inland delivery once the tiles reach your port, so there are no surprises.

- Payment: Standard payment terms for China tile suppliers are 30% deposit when you place the order, and 70% balance paid before the shipment (before the container is loaded or the Bill of Lading is released). This 30/70 term is common and generally non-negotiable for first-time orders. Make sure you’re prepared to send the balance promptly when production is done – a delay in payment will mean a delay in shipping your tiles. Use secure payment methods: bank T/T transfer is most common; for larger orders some buyers use a Letter of Credit for extra security. Verify the bank details directly with the supplier (watch out for phishing in email). Finally, ensure the payment timeline aligns with inspection: you should ideally do your QC check before paying the 70% balance, so any issues can be resolved while the money is still in your hand.

Having this checklist and discussing each point with your supplier will help you avoid misunderstandings. It sets clear expectations on both sides and makes your tile importing experience much smoother.

If you have tile sourcing needs, feel free to contact Miller at miller@kingsuntile.com, a professional tile manufacturer and exporter in China, for the latest catalogs, quotes, and purchasing support.

FAQ: China Floor Tile Buying & Wholesale Questions

Q: What documents should a China tile supplier provide for bulk export orders?

A: For a large tile export, you will need a commercial invoice, packing list, and bill of lading from the supplier. These are essential for customs. Often, the supplier will also provide a Certificate of Origin (especially if your country has a trade agreement with China for reduced tariffs) and possibly product test reports or certifications if required. Always ensure the paperwork is complete and matches the shipment (correct HS code, descriptions, quantities) to avoid customs issues.

Q: What is a realistic lead time for porcelain/ceramic tile wholesale orders from China?

A: Generally around 3-5 weeks production time for a full container order once your deposit is received is realistic for most factories . For example, many suppliers quote ~30 days production after confirming the order. Add to that the shipping time by sea (which can be another 2-6 weeks depending on your location). So, from order to arrival, expect roughly 6-8 weeks total. Simpler orders or in-stock items can be faster, while custom designs or very large orders might take longer.

Q: Can I mix different designs/sizes in one container? What are the trade-offs?

A: Yes, you can usually mix multiple tile designs or sizes in one container shipment. Chinese suppliers often allow a mix as long as you meet their MOQ per design (for example, they might require at least 200-500 m² of each design). The trade-offs are mainly logistical: mixing many types of tiles means more complex packing and labeling – you need to ensure pallets are clearly separated by product to avoid confusion on arrival. Also, if you only take a small quantity of a certain design, the price per unit could be a bit higher (you lose some bulk discount). In short, mixing is fine and common, but keep the variety to a reasonable level and coordinate with the supplier so the loading plan is well organized.

Q: How do I control color shade and caliber differences across production batches?

A: The best way is to order all tiles for a project in one batch from one production run. This ensures the tiles come out with the same shade tone and size calibration. If that’s not possible and you have to reorder later, always reference the original shade number and caliber number (printed on the tile box) and ask the supplier if they can match it. Good factories will keep records of their batches. It’s also wise to keep a couple of boxes from the initial batch as reference samples. Communicate clearly with the manufacturer that color consistency is critical – they can adjust glazes or select tiles to minimize variation. Lastly, during installation, mix tiles from different boxes/pallets randomly (if there were slight variations) so any minor shade differences blend in unnoticeably.

Q: What packaging best prevents breakage during sea freight (pallet vs wooden crate)?

A: For full-container loads, wooden pallets with proper stacking are the standard and are very effective. Tiles are packed in cartons, then stacked on pallets, wrapped tightly – as long as the container is filled and pallets don’t move, breakage is minimal. Wooden crates offer an extra level of protection since they enclose the tiles completely; these are often used for LCL (less than container load) shipments or very fragile decorative tiles. The downside is crates are heavier and add cost. In most cases, if you have a full container, sturdy pallet packing (with corner protections and shrink wrap) is sufficient to prevent breakage. Crates are a good idea if your shipment isn’t filling a container or if you want peace of mind for expensive items.

Q: FOB vs CIF for tile imports: which option is safer for distributors?

A: CIF (Cost, Insurance, Freight) is often seen as safer for newer importers because the supplier takes care of shipping and insurance up to your port. It simplifies logistics – you just have to handle customs clearance. The cargo is insured, so if something happens in transit, you’re covered (though insurance claims can still be a process). FOB (Free On Board), on the other hand, gives you control: you hire your own freight forwarder and you can often get better shipping rates or more direct routes. Many experienced distributors prefer FOB to have transparency on freight costs and control timing. In terms of risk, neither is inherently unsafe – it’s about convenience vs. control. If you don’t want to deal with arranging ocean freight, go CIF and let the supplier bear the risk until the goods arrive. If you have a trusted shipping partner and want to potentially save on costs, FOB is a fine option (just be sure to insure the shipment yourself).

Q: What are the common hidden costs when importing tiles (port fees, duty, local delivery)?

A: Aside from the cost of the tiles and ocean freight, importers should budget for import duties/tariffs on ceramic tiles (rate depends on your country’s customs). There will also be destination port charges such as terminal handling fees, document fees, maybe port security charges – these can amount to a few hundred dollars. If you use a customs broker, there’s a brokerage fee. After customs, you’ll have local transport costs: trucking the container from port to your warehouse (or unloading and delivering pallets). Don’t forget costs like unloading labor or equipment if you need a forklift. In some cases, there could be storage or demurrage fees if your container sits at the port too long after arrival. To avoid surprises, ask your freight forwarder for an estimate of destination charges in advance and ensure you’re clear on local delivery expenses.

Q: How do I set up pre-shipment inspection (PSI) and quality checkpoints for tile orders?

A: You can hire an independent inspection company to perform a Pre-Shipment Inspection (PSI) in China once your order is ready. Firms like SGS, Bureau Veritas, or Asia Inspection specialize in this – you book the service and provide them with details of your order and quality criteria. They will visit the factory, usually when the tiles are packed and ready, and they’ll randomly inspect tiles for defects, verify dimensions, thickness, surface finish, and check the packing. They’ll issue a report with results and pictures. To set this up, schedule the inspection to happen before final payment/shipping – typically during the last week of production. Additionally, it’s smart to have quality checkpoints earlier: for instance, get an initial sample from the first batch produced for your approval (especially if it’s a custom design), or even do an in-production check if it’s a very large order. Clear communication with the supplier is part of QC: send them your quality checklist (e.g., “glossy tiles must have no haze, size 600×600 ±0.5mm tolerance, all boxes labeled with same shade”). This way the factory knows you will be checking and they usually self-correct many issues before the final inspection.

Q: How do private-label buyers customize logos, cartons, and barcodes for tile distribution?

A: Most Chinese tile manufacturers offer OEM/private label services for distributors. When you place your order, tell the supplier you want custom packaging. Typically, you will need to provide the artwork: your logo file and the design layout for the carton or labels. The supplier’s design team can help if you give them the basic requirements (many have templates). You can have your brand logo printed on each tile box, your company name on the carton, and even custom barcodes or product codes as stickers. The minimum order for custom packaging is usually one full container (since the factory has to print a batch of boxes with your logo). There might be a small additional cost for printing, but often if the order is large, factories do it free of charge. Ensure you review the mock-up of the box design that the supplier provides. Details like the label content (tile model name, size, shade, caliber, your logo, “Made in China”, etc.) should be confirmed. Once everything is set, the factory will use those custom cartons and it will look like your own brand of tiles when you receive them. This is a great way for distributors to build their brand – just plan for a bit of extra time upfront to coordinate the artwork and printing with the supplier.