Sintered stone countertops are gaining popularity as a cutting-edge option for modern kitchens and bathrooms. This engineered material promises the beauty of natural stone with enhanced durability1 and minimal maintenance. In this guide, we explore what sintered stone is, why it's chosen for countertops, and its key benefits and drawbacks. We also compare sintered stone to other popular surfaces like quartz and granite in terms of cost, maintenance, and performance. Finally, you'll find practical usage tips, maintenance advice2, and a look at the material's sustainability to help decide if a sintered stone countertop is the right investment for your home.

What is sintered stone?

Sintered stone3is an engineered stone material created by fusing natural minerals under extreme heat and pressure. Through a process called sintering, a mixture of stone particles (such as quartz, feldspar, silica, and other minerals) is compressed and baked at very high temperatures until the particles bond together into a solid slab. Unlike quartz countertops which use resin binders, sintered stone contains little to no resin; it is essentially a porcelain-like slab composed almost entirely of natural minerals. The result is an incredibly dense, non-porous4, and durable surface that mimics the look of natural stone while offering superior strength and consistency. Sintered stone slabs are ideal for countertops, flooring, and wall cladding – anywhere a strong, low-maintenance, and aesthetically pleasing surface is desired.

Why choose sintered stone for countertops?

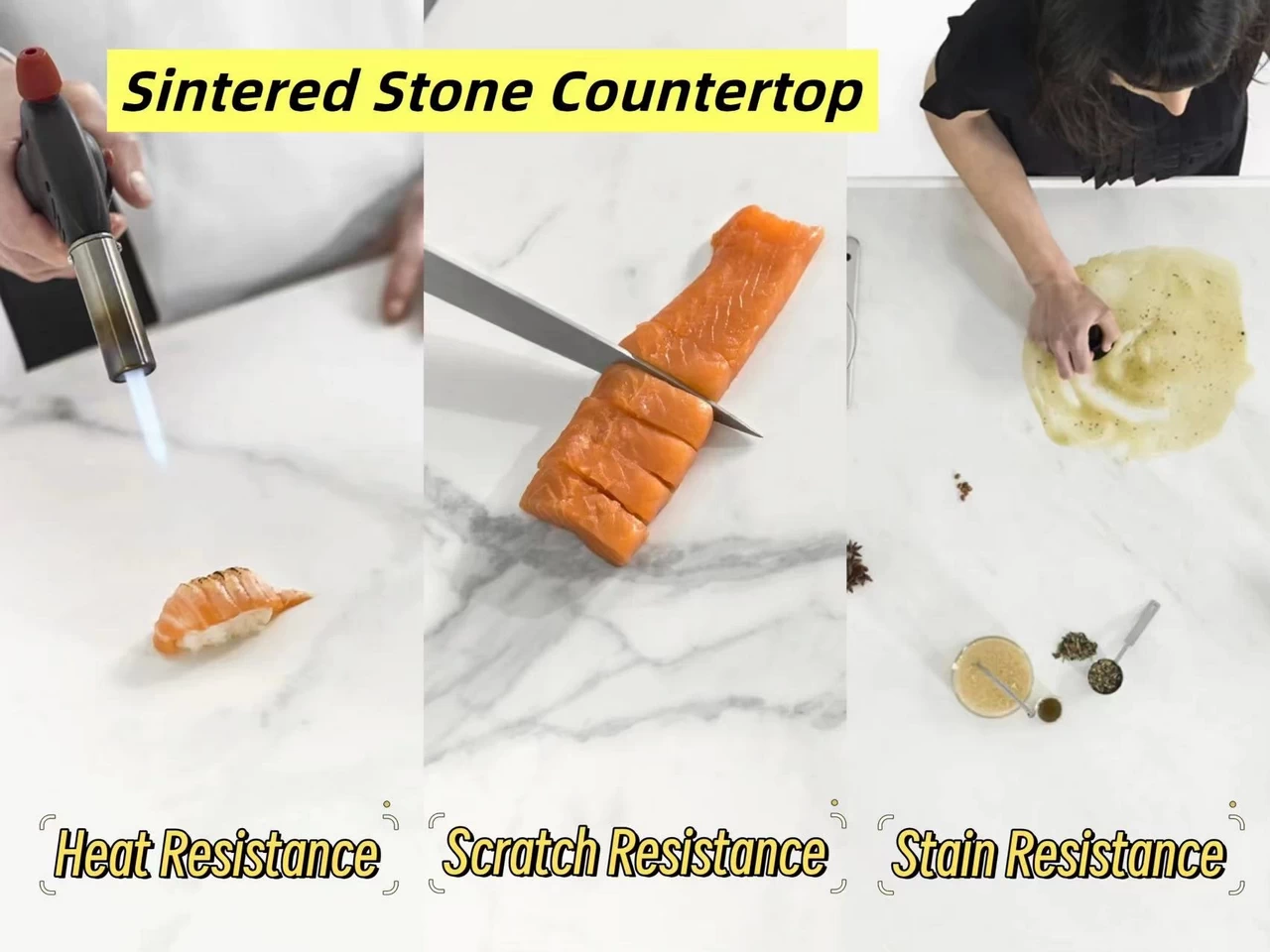

- Exceptional Durability: Sintered stone is one of the hardest and most wear-resistant countertop materials available. It resists scratches, cracks, and chips under normal use, handling heavy daily kitchen activity without visible damage.

- Heat and Fire Resistance: Thanks to its manufacturing process, sintered stone can tolerate very high temperatures. You can place hot pots and pans directly on a sintered stone countertop without worrying about scorch marks or thermal shock (unlike materials with resins, such as some quartz, which can be damaged by heat).

- Non-Porous & Stain-Proof: The surface of sintered stone is virtually non-porous, so it will not absorb liquids or stains. Spills — from red wine to coffee or oil — can be wiped up easily without leaving a trace, and the countertop never needs sealing to remain impervious to moisture and bacteria.

- UV Resistant & Outdoor-Friendly: Sintered stone doesn't fade or discolor when exposed to sunlight. Its UV resistance means it can be used in outdoor kitchens or in sunny indoor spaces without losing its color or finish over time, something that many other countertop materials cannot promise.

- Wide Range of Designs: Because it's man-made, sintered stone comes in a variety of colors and patterns, many of which convincingly mimic natural stone like marble, granite, or slate. It is available in large slab formats, allowing for expansive, seamless countertop installations with minimal joints, and it can be fabricated into custom shapes or curved surfaces to fit cutting-edge kitchen designs5.

- Low Maintenance: Daily care for sintered stone is simple — usually just a wipe with a soft cloth, mild soap, and water keeps it looking pristine. Unlike granite or marble, it never needs periodic sealing or special treatments, saving you time and maintenance costs over the life of the countertop.

Pros and cons of sintered stone countertops

Pros:

- Extremely durable (resists scratches, heat, stains, and UV rays)

- Non-porous and hygienic (does not require sealing)

- Easy to clean and low maintenance

- UV-stable (suitable for outdoor use without fading)

- Wide variety of colors and realistic stone patterns

- Environmentally friendly (contains low silica and is often recyclable)

Cons:

- Higher initial cost compared to some traditional materials

- Requires professional installation6 (not DIY-friendly)

- Edges can chip if hit by very heavy objects

- Limited suppliers and fabricators in some areas (newer product on the market)

- Pattern or color may only be surface-deep (the sides/edges might not have the same pattern as the top)

Durability: Is sintered stone prone to cracking or chipping?

- High Resistance to Cracks: Under normal household use, a sintered stone countertop is very unlikely to crack. Its dense, engineered structure can withstand heavy loads and everyday impacts without fracturing.

- Not Easily Chipped by Daily Use: Sintered stone’s hardness means it doesn’t chip from minor bumps or regular kitchen activities. In comparison to more brittle surfaces like ceramic tile or a soft natural marble, it holds up exceptionally well against chipping and wear.

- Edges Need Care: The main surface of a sintered stone countertop is extremely tough, but as with any stone material, the edges and corners can be vulnerable if struck with force. For example, dropping a cast-iron pan directly on a sharp edge could cause a chip in the countertop (a caution that equally applies to granite or quartz). Being mindful of heavy objects around the edges will virtually eliminate this risk.

- Professional Installation Prevents Issues: Most instances of cracking with sintered stone occur during fabrication or installation rather than during use. It’s important to use experienced professionals who will properly support the slab (especially around cutouts for sinks or cooktops) and handle the material correctly. With a proper install, the risk of cracks forming later on is extremely low.

Sintered stone vs quartz: which is better?

- Durability & Hardness: Both sintered stone and quartz are durable, but sintered stone is generally harder and more resistant to abrasions. Quartz is tough as well, but its resin binders make it slightly more prone to scratching or denting from sharp impacts compared to the ultra-dense structure of sintered stone.

- Heat and UV Resistance: Sintered stone can withstand high heat and direct sunlight without damage. You can safely place hot cookware on it, and it won’t discolor in sunlight. Quartz countertops, by contrast, can be scorched by excessive heat (hot pans may leave marks or cause cracking) and they can yellow or fade with prolonged UV exposure, so they are not recommended for outdoor use.

- Maintenance: Both materials are non-porous and very easy to maintain day-to-day. Neither requires sealing, and both can be kept clean with simple soap and water. However, harsh chemicals should be avoided on quartz because they can sometimes react with the resin, whereas sintered stone’s purely mineral composition is more chemically inert.

- Appearance Options: Quartz offers a huge array of colors and patterns, often with a uniform, consistent look (some designs mimic natural stone, others are very contemporary). Sintered stone also comes in many designs and can replicate natural stone veining with remarkable realism; additionally, sintered stone slabs are available in large formats and thinner profiles, enabling a sleek, continuous look with fewer seams. Both materials provide a lot of aesthetic flexibility, but sintered stone might edge out quartz for achieving large seamless surfaces or bold, marble-like patterns.

- Cost & Availability: Quartz has been mainstream longer and is widely available in many price ranges (from budget-friendly to premium). Sintered stone is a newer entrant and initially tended to be pricey, but its cost is now often comparable to high-end quartz. In some regions, you might find more fabricators and installers familiar with quartz, simply due to its longer market presence, whereas sintered stone may have more limited availability depending on local suppliers.

Sintered stone vs granite: cost, maintenance & performance

- Cost: Granite and sintered stone are both premium countertop options, but their pricing can differ. Granite prices vary widely: there are some relatively affordable, common granite colors as well as very expensive exotic slabs. Sintered stone was once generally at the higher end of the price spectrum due to its advanced manufacturing process, but as production expands it has become more competitive in price7. In many cases today, a sintered stone countertop will cost about the same as a mid-to-high range granite countertop of similar size, and in some markets it can even be a bit less expensive for comparable quality. Both materials are an investment, but the gap in cost between granite and sintered stone has narrowed considerably.

- Maintenance: When it comes to upkeep, sintered stone has a clear advantage. Granite is a natural stone that is porous to some degree, so it requires periodic sealing (usually every 1-3 years) to protect against stains and moisture. Granite owners must also be cautious with acidic spills (like wine or lemon juice) which can etch or discolor the stone if it’s not properly sealed. Sintered stone, on the other hand, never needs sealing – its non-porous surface is inherently stain-resistant and doesn’t harbor bacteria. Cleaning granite and sintered stone on a daily basis is similarly easy (just mild soap and water), but granite’s maintenance demands (regular sealing and prompt spill cleanup) are higher over time. Sintered stone offers a virtually maintenance-free experience aside from routine cleaning, which is a major convenience for busy homeowners.

- Performance: Both granite and sintered stone are exceptionally durable, but they have different strengths due to their nature. Granite is very hard and handles scratches and heat well – you can often cut on it or set down a hot pan without immediate damage (though using cutting boards and trivets is still recommended to protect your tools and the finish). Sintered stone matches or exceeds granite in these respects: it is equally scratch-resistant and even more heat-resistant (it won’t crack from sudden temperature changes). Unlike some natural stones, sintered stone has no inherent fissures or weak veins, giving it a very consistent strength throughout. Additionally, sintered stone is completely UV-stable, so it won’t fade or weather even in outdoor kitchens or sun-drenched rooms; granite, while generally okay in sunlight, can sometimes experience slight color changes or surface dulling over many years if exposed to the elements. Neither material is easily chipped or cracked during normal use, and both can last for decades. However, if damage does occur, granite has the benefit of being the same material throughout – a small chip can sometimes be filled and repolished to match the original look. Sintered stone can be more challenging to repair invisibly if chipped, especially if the chip exposes a slightly different inner color. Overall, sintered stone provides more uniform performance (stain-proof, heat-proof, etc.), while granite offers the timeless appeal and natural uniqueness that some homeowners love.

Is sintered stone more expensive than other countertop materials?

- Porcelain Tile Countertops: Typically the most budget-friendly option – basic porcelain or ceramic tile countertops cost less per square foot than any slab material (around \$30–\$70 per sq. ft. installed, depending on the tile).

- Sintered Stone Countertops: Priced slightly above standard porcelain, but now often more affordable than quartz, granite, or marble of similar quality. You can expect roughly \$60–\$100 per sq. ft. installed for sintered stone, though prices continue to trend downward as it becomes more common.

- Quartz Countertops: Generally a mid- to high-range option, usually around \$70–\$120 per sq. ft. installed. Some entry-level quartz can be cheaper than sintered stone, but high-end quartz brands or elaborate designs can actually cost the same or more.

- Granite Countertops: Granite costs vary widely based on the type of stone – roughly \$50–\$140 per sq. ft. installed. There are inexpensive granite options at the lower end, but many popular or premium granite styles will fall in the same range or higher than current sintered stone prices.

- Marble Countertops: Marble is typically on the higher end of the cost spectrum. Installed prices often run about \$70–\$150+ per sq. ft., making marble one of the more expensive choices. Its luxurious appeal comes with both a higher price and additional maintenance requirements (which add to its lifetime cost).

Overall, sintered stone is not the most expensive countertop material today. In fact, with increased production and competition, its pricing has become quite competitive with other high-end surfaces. In many scenarios, a sintered stone countertop will cost less than a premium quartz, granite, or marble countertop, while delivering equal or better performance. It remains only slightly more expensive than basic porcelain slabs, reflecting its advanced properties, but the small premium can be well worth it given the benefits.

Maintenance & cleaning tips for sintered stone

- Daily Cleaning: Use a soft cloth or sponge with warm water and a bit of mild dish soap to wipe down the countertop after use. Because the surface is non-porous, routine spills and light grime come off easily without any special cleaners.

- Avoid Abrasive Cleaners: Steer clear of steel wool, scouring pads, or harsh abrasive powders that could dull the surface’s finish. Although sintered stone is highly scratch-resistant, cleaning with gentle materials (like microfiber cloths or non-scratch sponges) will help maintain its sheen over time.

- No Sealing Required: Unlike natural stone surfaces, you never need to apply a sealing product to sintered stone. Its non-porous composition means it’s already impervious to liquids and stains without any additional treatment, saving you an important maintenance step.

- Prompt Spill Wipe-Up: While sintered stone won’t stain from most substances, it’s still good practice to wipe up strongly colored or acidic spills within a reasonable time. Substances like red wine, coffee, or lemon juice can simply be cleaned with soapy water, but cleaning them sooner rather than later ensures absolutely no residue is left on the surface.

- Stubborn Stains: For the rare sticky or dried-on mess, use a pH-neutral household cleaner or a gentle cream cleanser recommended by the manufacturer. You can also apply a paste of baking soda and water to a spot and let it sit for a few minutes before gently wiping – since the stain cannot penetrate, it should lift without much effort. Avoid very harsh chemicals (like concentrated bleach or acids) as they are unnecessary and could potentially discolor the surface finish.

- Use of Trivets and Cutting Boards: Even though sintered stone can handle hot pans directly, it's wise to use trivets or hot pads for cookware just off the stove – this is more to protect your cookware and be extra cautious with your countertop’s finish. Similarly, use cutting boards when chopping or slicing; the countertop won’t likely scratch, but cutting on such a hard surface can dull your knife, and heavy chopping might leave metal marks that then need cleaning. Following these basic precautions will keep your countertop and your kitchen tools in great shape.

- General Care: Day-to-day, simply keeping the countertop free of gritty dirt and wiping it down is enough to preserve its beauty. Because there are no pores, you don’t have to worry about bacteria or mold growth in the material – a great benefit for a hygienic kitchen. Sintered stone is designed to stay looking like new with minimal effort, so with basic care, your counters will retain their original look for many years.

Environmental impact and sustainability

- Safer Manufacturing (Low Silica): Sintered stone is typically made with little to no crystalline silica, which is a health hazard in countertop fabrication (silica dust can cause silicosis in workers). By reducing or eliminating silica content, the production and cutting of sintered stone is safer for factory workers and installers, contributing to better occupational health standards.

- Recyclability: Sintered stone is an environmentally friendly choice at the end of its life cycle as well. Old or broken sintered stone slabs can be crushed and recycled into new building materials or aggregates. This recyclability means less material ending up in landfills and more efficient use of raw resources.

- No Harmful Emissions: Since sintered stone slabs contain no resin binders or VOC-heavy components, they do not off-gas harmful chemicals into your home. They also don’t require the frequent application of chemical sealants or polishes. This translates into better indoor air quality and a lower usage of harmful chemicals over the countertop’s lifespan.

- Longevity Reduces Waste: The exceptional durability of sintered stone means that once installed, it can last for decades without needing replacement. By not having to replace your countertops as often (as might be the case with laminate or other less durable materials), you reduce the consumption of resources and the waste associated with torn-out old countertops. In a long-term perspective, choosing a durable product like sintered stone can be considered a sustainable decision.

- Energy and Resource Considerations: Manufacturing sintered stone does consume significant energy (due to the high heat required), but many producers are improving efficiency and utilizing greener practices. Some brands incorporate recycled mineral content into their slabs, and others invest in renewable energy or emissions controls in their factories. Additionally, by using engineered slabs, there may be less demand for quarrying large blocks of natural stone from the earth. This could help preserve natural landscapes and reduce the environmental disruption associated with mining. In summary, while production has an environmental footprint, the combination of long lifespan, recyclability, and reduced maintenance chemicals makes sintered stone a generally eco-conscious choice among countertop materials.

Is sintered stone worth the investment?

- Long-Term Value: Sintered stone may have a higher upfront cost than some traditional materials, but it offers significant long-term value. Its robustness means you likely won’t need to replace it for a very long time (it can easily last for decades), and it will maintain its appearance with minimal upkeep. Over the lifespan of your kitchen, the cost of a sintered stone countertop can be offset by the savings on maintenance and the longevity of the material.

- High Performance Benefits: The everyday performance of sintered stone adds to its worth. Homeowners who do a lot of cooking, entertaining, or simply don’t want to worry about their counters will appreciate that hot pans, sharp knives, acidic foods, and spills won’t easily damage the surface. This worry-free durability and convenience can make the higher initial investment feel absolutely justified, as you enjoy a beautiful countertop without stress or extra costs for repairs and maintenance.

- Comparison to Alternatives: When compared to other premium surfaces (like high-end quartz, granite, or marble), sintered stone often gives you equal or better results for a similar cost. You get the luxurious look of a natural stone like marble and the toughness that exceeds granite, all in one product. If you are already considering spending the money on a quality countertop, choosing sintered stone can be a smarter investment because you’re getting top-tier durability and low maintenance in addition to style.

- Resale Value & Aesthetics: Installing a modern, high-quality material like sintered stone can also add value to your home. Its sleek, upscale appearance and reputation for durability may be a selling point if you ever put your home on the market. Prospective buyers often appreciate kitchens with durable, stylish countertops, so your investment could make your home more attractive and potentially command a higher resale price or quicker sale.

- Personal Priorities: Ultimately, determining if sintered stone is “worth it” comes down to your personal priorities and budget. If you prioritize having a countertop that looks high-end, performs exceptionally under all conditions, and requires almost no maintenance, then a sintered stone countertop is likely worth the investment for you. On the other hand, if your project budget is very tight and your countertop won’t see heavy use, you might opt for a less expensive material and accept the trade-offs. For many homeowners, however, the combination of beauty and brawn that sintered stone provides makes

it a very compelling choice despite the upfront cost.

Conclusion: Sintered stone countertops blend the appeal of natural stone with the advanced performance of modern engineering. They offer an impressive mix of strength, heat resistance, stain resistance, and longevity, all while looking beautiful in a variety of designs. There are some considerations to keep in mind — notably the need for professional installation and a cost that, while coming down, is still comparable to other premium materials. However, the minimal maintenance and long-term durability of sintered stone mean that it often pays for itself over time. As production continues to increase and the material becomes even more accessible, sintered stone is poised to become a staple in kitchens and bathrooms. In the end, if you’re seeking a countertop that can truly do it all and stand up to the demands of daily life, sintered stone countertops are certainly worth strong consideration.

-

Discover the durability of sintered stone countertops and why they are a popular choice for high-traffic areas. ↩

-

Get expert maintenance tips to keep your sintered stone countertops looking pristine for years. ↩

-

Want to dive deeper? Read our detailed guide on "What's Sintered Stone?" to understand how it’s made and why it stands out. ↩

-

Understand the advantages of non-porous surfaces in preventing stains and bacteria, crucial for kitchen hygiene. ↩

-

Explore the latest trends in kitchen design that incorporate innovative materials like sintered stone. ↩

-

Understand the importance of professional installation to avoid issues and ensure the longevity of your countertop. ↩

-

Curious about costs? Check our "Sintered Stone Price" article to see the latest FOB factory prices from China. ↩