China is a global hub for tiles, producing a vast range of ceramic and porcelain tiles at competitive prices. The country’s tile industry has evolved from just high volume to a focus on quality and innovation, making it attractive for importers worldwide. However, finding a reliable China tile supplier1 means looking beyond price. A truly reliable supplier will meet international standards (e.g. CE certification for Europe, ISO 9001 quality management), maintain consistent quality control, and offer professional service from production to export. In short, “reliable” in the tile industry means a supplier who delivers what they promise in terms of compliance, product quality, and support.

Step 1 — Define Your Specs Like a Buyer (So Suppliers Can’t “Vague Quote” You)

The more precise your specs, the less room suppliers have to give vague quotes. Clearly defining your requirements forces suppliers to quote based on your actual needs rather than generic terms like “high quality”. At minimum, provide critical specifications; you can also share additional helpful details if available. Here’s a simple breakdown:

| Must Provide (for an accurate quote) | Optional But Helpful (adds clarity) |

|---|---|

| Tile type & category (porcelain vs ceramic, with target water absorption rate if known) | Preferred standards (if any, e.g. compliance with EN or ISO tests for water absorption, strength) |

| Dimensions & thickness (e.g. 600×600 mm, 10 mm thick) | PEI wear rating (for floor tiles, e.g. PEI IV for commercial use) |

| Surface finish (glossy, matte, polished, honed, etc.) | Slip resistance rating (for tiles in wet areas, e.g. R11 for outdoor anti-slip) |

| Design/color (or reference to a pattern or style) | Packaging requirements (specific box labeling or pallet packing requests) |

| Quantity needed (in square meters or number of cartons) | Any test reports you expect (e.g. want tiles tested to certain standards) |

By providing detailed specs like the above, you prevent suppliers from giving you a “vague quote” based on incomplete information. It also shows the supplier you know what you’re looking for, which helps in getting a realistic price and appropriate product recommendations.

Step 2 — Where to Find a China Tile Supplier (Google + Platforms + Trade Shows)

Google Search: Start with a simple Google search using keywords like “porcelain tile supplier in China” or “Foshan ceramic tile manufacturer”. Look beyond the first page and check suppliers’ websites for product range, export experience, and client testimonials. A well-maintained English website with detailed product info and certifications is a good sign.

Online B2B Platforms: Websites such as Alibaba, Made-in-China, and Global Sources host thousands of Chinese tile suppliers. Use platform filters (e.g. “Verified Supplier”, minimum years in business, customer reviews) to narrow down reputable options. These platforms allow you to compare prices, MOQs, and see if suppliers have badges like “Gold Supplier” or export certificates.

International Trade Fairs: Events like the Canton Fair or specialized expos (e.g. CeramBath in Foshan) are prime places to meet tile manufacturers and trading companies in person. Visiting a trade show lets you see tile samples up close, gauge the supplier’s professionalism, and discuss your needs face-to-face. Trade fairs also help you spot new design trends and collect multiple contacts in a short time.

Networking & Referrals: If you’re in the building materials community, ask peers if they have trusted Chinese tile suppliers. Often, word-of-mouth referrals lead to reliable suppliers that don’t heavily advertise online. Additionally, some buyers work with sourcing agents based in China who already have a network of vetted tile factories.

(Tip: For large or long-term projects, consider visiting China’s tile production hubs like Foshan or Qingdao in person. On-site visits allow you to verify a factory’s scale, equipment, and quality control processes directly.)

Step 3 — Factory or Trading Company? Choose Based on Risk, Not Emotion

Factory (Manufacturer): Sourcing directly from a tile factory gives you more control over production, costs, and quality. You avoid the mark-up of middlemen, which can make pricing very competitive. Factories are ideal if you have a large order volume with fairly standard specifications and you have the experience (or resources) to manage quality inspection and logistics yourself. Keep in mind that factories often have higher MOQs and may be less flexible on product variety since they specialize in what they produce.

Trading Company: A trading company acts as an intermediary but offers flexibility and convenience. Good trading companies can consolidate products from multiple factories, offer smaller MOQs, and handle the export paperwork, logistics, and even after-sales coordination for you. They essentially serve as your one-stop export department. This can be a safer choice for first-time importers, those doing mixed product orders, or anyone who wants to simplify the process. You might pay a bit more per tile (Tile is a highly competitive product, actually trading companines' margins are usually only 5–10%), but in return you gain easier communication and a buffer against production risks (since the trader will resolve issues behind the scenes).If a trading company has long-term cooperation with a factory in a strong category, its purchase price can be even lower than what a new buyer gets by asking the factory directly.

Summary – How to Choose: Let your circumstances drive the decision. If you’re placing a very large, consistent order of a specific tile and have strong confidence in managing quality and shipping, working directly with a factory can save money. However, if your order is smaller, includes various types of tiles, or if you are new to importing, a reputable trading company is often lower risk. Many importers start with a trading company to get their feet wet – as trust is built and knowledge of the industry grows, you can then consider dealing directly with the factory for cost savings on repeat orders.

Step 4 — Verify Credentials: Certificates, Test Reports, and Red Flags

Before you commit to any China tile supplier, always verify their credentials and documentation. A reliable supplier should not hesitate to provide proof of their qualifications. Key things to check include:

Business Legitimacy: Ask for a copy of their business license and (if applicable) an export license. A genuine company in China will have a valid business registration and the rights to export. This basic step ensures you are dealing with a legally registered entity, not a fly-by-night operation.

Quality Management Certification: ISO 9001 certification is a global standard that shows the company follows a quality management system. If a supplier has ISO 9001, it’s a baseline indication that they have documented processes for maintaining product quality and consistency.

Product Compliance & Test Reports: For tiles, ask for any product certifications required by your market (for example, CE marking if you import into the EU, which indicates the tiles meet EU safety and performance standards). Equally important, request recent third-party test reports for the tiles. These are lab reports from recognized agencies like SGS, Intertek, or Bureau Veritas, showing the tile’s performance on key standards (e.g. water absorption, breaking strength, abrasion resistance per ISO 10545 or EN standards). Authentic reports give you hard data that the supplier’s tiles meet the claimed specs.

Red Flags: Be alert for warning signs during the verification process. If a supplier cannot or will not provide up-to-date test reports, that’s a bad sign. Beware of certificates or test reports that look fake or come from unverifiable agencies. Mismatches are also red flags – for example, if a CE certificate is provided but it’s for a different company or product category. Expired documents or evasiveness about credentials are signals to think twice. A reliable tile supplier will be transparent and proactive in proving their reliability.

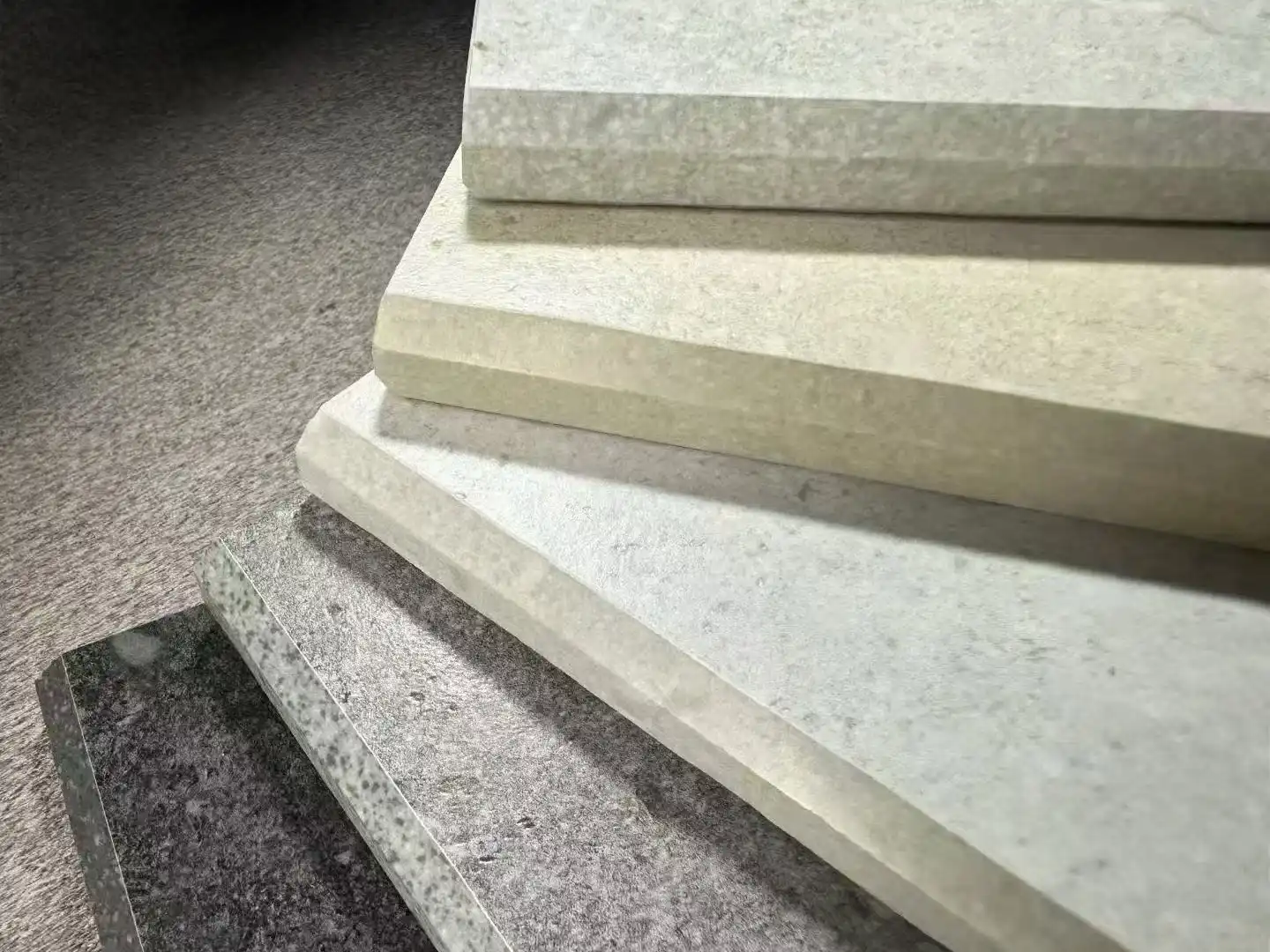

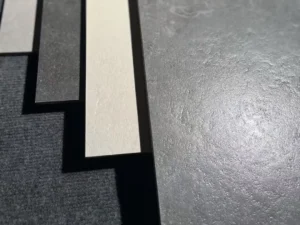

Step 5 — Samples & Shade Control: How to Avoid “Looks Good in Photos”

A common buyer complaint is that the tiles looked perfect in pictures, but the actual shipment wasn’t what they expected. To avoid these surprises, take concrete steps during sampling and production to control quality and color consistency:

Seal a “Golden Sample”: Always request a physical sample of the tile from the supplier’s production. Once you receive a sample that meets your expectations, seal and sign this “golden sample”2 (both you and the supplier keep one). This sample becomes the standard reference for production. It ensures everyone agrees on what the product should look like (color, pattern, finish) and is used later to compare against bulk goods.

Enforce Shade/Lot Consistency: Shade variation can occur in tile production, especially for porcelain tiles with complex glazes or inkjet prints. To minimize this, insist that your entire order is produced in one batch (one lot) with a unique shade number/lot number. In practice, for a large order the factory should run all those tiles through the kiln in as continuous a sequence as possible. This greatly reduces the chance of noticeable color variation. Make sure the lot number is marked on the packaging, and avoid mixing lots in one order.

Request Real-Time Production Visuals: Don’t be shy about asking for photos or even short videos during production. A reliable supplier will update you at key stages – for instance, when the tiles come out of the kiln or when they start packaging. These real-time visuals let you see that the product matches your golden sample and specifications. It’s much easier to address any issue (color off, wrong finish, etc.) before everything is packed and shipped. Plus, it keeps the supplier aware that you are monitoring quality closely.

By focusing on samples and shade control, you significantly reduce the risk of the classic “looked good in photos, but…” problem. You’ll know that the tiles heading your way are exactly what you approved.

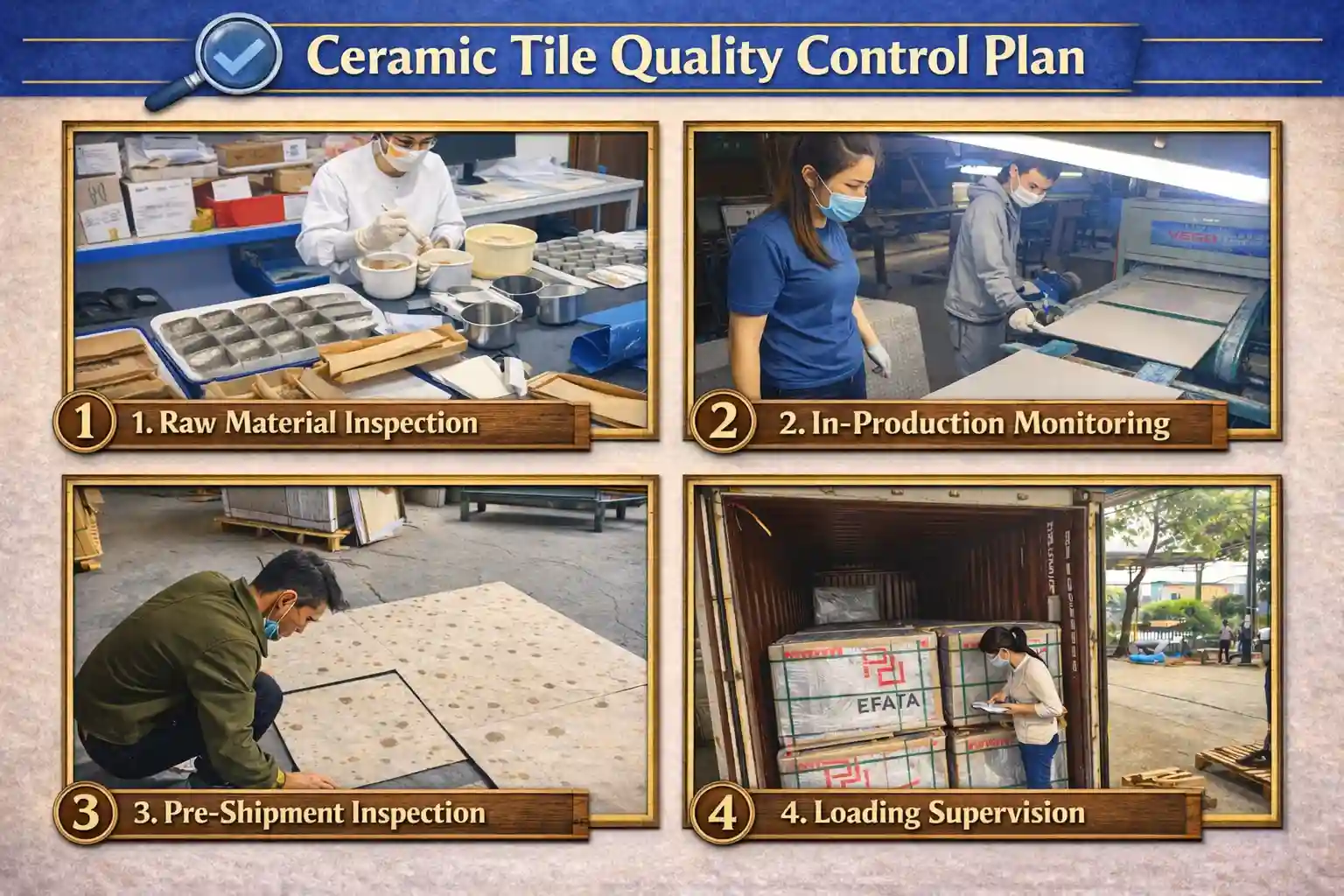

Step 6 — Quality Control Plan (Before, During, and Before Shipment)

Quality control shouldn’t just happen at the end – it needs to be planned at every stage of production. Develop a QC plan that covers before production, during production, and pre-shipment checks. For example, before production, you might verify raw materials or glazes to be used (especially for custom orders). During production, you or your agent might inspect semi-finished tiles coming out of the kiln to catch issues early. The most crucial step is the pre-shipment inspection3 – a final check of the goods when production is complete but before they ship out. Below is a Ceramic/Porcelain Tile Inspection Checklist outlining key points to cover in that final inspection. Each point should be verified against your specs or golden sample:

Ceramic/Porcelain Tile Inspection Checklist (Pre-Shipment):

Packaging & Labeling: Check that cartons are sturdy and sufficiently protect the tiles (export-worthy packaging). All boxes should have clear labels with the product name, size, grade, shade/lot number, quantity, and gross/net weight. Proper packaging ensures tiles won’t break in transit and correct labeling is vital for easy sorting on arrival.

Quantity & Batch Consistency: Verify the total quantity against the order and ensure it matches the packing list. During random carton checks, confirm all tiles are from the same production batch/lot (the lot number should be identical on all boxes). Consistent batch numbers mean the color and caliber of tiles will be uniform across your order.

Visual Appearance: Inspect tiles under good light for any obvious defects. This includes looking for cracks, chips, pinholes, glaze imperfections, or spots on the surface. Also line up multiple tiles to see if there’s any noticeable color variation beyond what’s acceptable. AQL (Acceptable Quality Level) sampling can be used here – for example, check a certain number of tiles per lot size to statistically ensure the batch is fine.

Dimensions & Shape: Use a caliper or measuring tape to spot-check the length, width, and thickness of tiles against the specifications. All tiles should be within the allowed tolerance (e.g., ±0.5% or whatever was agreed). Also check edge straightness and corner right angles by aligning tiles together – tiles should form a straight line and right angle corners without warping. Proper calibration ensures the tiles will install evenly with uniform grout lines.

Flatness & Warpage: Place a few tiles face-to-face and see if they sit flush with each other (or place one tile on a truly flat surface). This reveals any warping or bowing. Tiles should lie flat without significant gaps or rocking. Excessive curvature can cause installation issues (hollow spots under tiles or uneven floors), so this is critical especially for larger format tiles.

Surface Finish & Texture: If your tile is supposed to be matte, polished, or textured, feel the surface and visually confirm the finish is correct on each piece. The gloss level should match the golden sample (e.g., polished tiles should have that mirror shine without hazy spots; matte tiles should not have unexpected glossy patches). For anti-slip tiles, you can do a quick subjective slip test (the surface should feel gritty or textured enough to provide traction).

Random Installation Check: If possible, take a few tiles from different boxes and put them together as if you’re laying them on a floor or wall. This way, you can see the overall effect – check that the pattern aligns (for printed designs), the color shades match well across the tiles, and that the tiles sit well together without obvious size differences.

Verification of Tests (if required): If your contract called for any specific lab tests or on-site tests (like water absorption percentage, or breaking strength for a sample tile), ensure those were conducted and the results are available. Typically, the supplier would provide a lab report or you might have a third-party inspector do this. For example, porcelain tiles should have water absorption ≤ 0.5% – if critical to you, verify a sample from the batch was tested.

Documentation Check: Lastly, make sure all paperwork is in order. This includes the commercial invoice, packing list, bill of lading, and any required certificates (like Certificate of Origin, or test certificates for customs). The details on them (product description, quantities, weights) should match the physical goods. Mistakes in documents can cause customs clearance delays, so this final check is important too.

By following a thorough inspection checklist, you can catch any issues before shipment. If something is wrong, you have the ability to ask the supplier to rework or replace affected tiles before they depart China, saving you headaches later.

Step 7 — Lead Time, MOQ, and Logistics (What Realistic Looks Like)

Importing tiles successfully means planning around realistic production and shipping timelines. Here’s what to expect regarding lead times, minimum order quantities, and logistics:

Realistic Production Lead Time: Generally, once you place an order and pay a deposit, a standard tile order will take around 20–30 days to produce before it’s ready to ship. This can vary a bit depending on the factory’s workload and the specific tile (a common item might be faster, a custom or very large format tile might take longer). Be wary of any supplier promising unrealistically short lead times; quality tile production, including kiln firing and cooling, cannot be rushed too much.

MOQ (Minimum Order Quantity): Most Chinese tile suppliers set MOQ by one 20-foot container. A common range is around 1,000–1,400 sqm, depending on tile size and thickness. If you want to reduce risk on the first order, you can negotiate with the supplier to load 4–6 items in one 20-foot container. This works best when the items share similar packaging and loading requirements, so the container can be packed safely and efficiently.

Logistics & Incoterms: Always clarify the shipping terms in your contract. The most common terms are FOB (Free On Board) and CIF (Cost, Insurance & Freight). For example, FOB Foshan means the price covers delivery of tiles to the port and onto the ship in Foshan, but you handle freight and insurance after. CIF includes ocean freight to your destination port (e.g. CIF Los Angeles) and usually basic insurance. If you go with CIF, still educate yourself on the destination charges (like port fees, customs duty, local trucking) because those will be your responsibility. No matter the term, insure your shipment – either through the supplier or your own cargo insurance – for peace of mind. And ensure you or your freight forwarder track the shipment closely so it doesn’t get held up unnecessarily at the port.

(Note: Ocean transit time is separate from production lead time. From China to North America or Europe, transit can add another 2–5 weeks depending on the port. Plan your inventory accordingly.)

Step 8 — Payment Terms & Contracts That Protect You

Even with a trustworthy supplier, a solid contract and clear payment terms are your safety net. Here are critical points to include, each explained:

Standard T/T Payment Terms: Most Chinese tile suppliers use Telegraphic Transfer (T/T) for payment. A typical arrangement is 30% deposit upfront, 70% balance before shipment. This means you pay 30% to start production, and you pay the remaining 70% when the tiles are finished but before they are released or loaded on the ship. For the first order, this is standard. After you build a good relationship, you might negotiate slightly better terms (for instance, 70% balance against a copy of the Bill of Lading, which lets you pay after the tiles have shipped out, giving you more assurance). A Letter of Credit could be used for very large orders but many suppliers prefer T/T due to simplicity).

Use Golden Sample & Specs as Quality Baseline: Your contract should clearly state the quality and specification standards the supplier must meet. The easiest way is to reference the sealed golden sample and any technical standards. For example, include a clause that says “Product must match approved sample dated X, and meet performance criteria per Annex Y.” Annex Y could be a list of key specs like tile size tolerance, water absorption rate, PEI rating, etc., ideally referencing international standards (EN/ISO or ASTM tests) for clarity. By writing the golden sample and standards into the contract, you have a concrete baseline to judge the product. If the tiles deviate significantly from the sample or fail the agreed standards, the contract should consider it a breach requiring remedy.

Inspection and Claims Clause: Protect yourself by including terms about inspection and what happens if issues are found. For instance, you can state that you (or a third-party inspector) have the right to do a pre-shipment inspection at the factory. Define the acceptable quality level (for example, “AQL 2.5 for major defects, 4.0 for minor defects” or any criteria you choose). Also outline the procedure if the tiles don’t meet requirements: maybe the supplier must replace or rework defective tiles, or you can negotiate a discount for minor issues. Importantly, set a timeline for claims after you receive the goods – e.g. you have 14 days after arrival to notify the supplier of any quality problems. This way, if you discover hidden issues upon unpacking, you can still seek a solution. The contract should mention remedies, such as the supplier agreeing to refund or send replacement tiles, or other compensation, in case of significant quality issues confirmed after delivery.

IP and Design Protection: If you’re buying tiles that involve proprietary designs (for example, you gave the supplier a custom pattern to produce, or you have your own brand on the product), include a clause on intellectual property. Make it clear that you retain ownership of your designs/brand and that the supplier should not sell your exact tile design to others or infringe on any third-party IP. Additionally, you can include confidentiality clauses if you’re sharing any sensitive information. While IP might not be a concern for generic tiles, for custom designs or branded orders it’s important. Even for generic orders, you should have a clause confirming the tiles do not violate any patents or trademarks (so you don’t end up importing goods that get you in legal trouble in your market).

A well-drafted contract coupled with sensible payment terms significantly lowers your risk. It aligns expectations on both sides and provides a roadmap for what to do if something goes wrong. Never rely on just a verbal promise or simple Proforma Invoice for large purchases – invest the time to get the terms in writing.

Step 9 — Communication Workflow (Fix the #1 Pain Point for Buyers)

Many importers say the biggest pain point when dealing with overseas suppliers is poor communication. For example, Victor Lee, an experienced tile buyer, noted that delays in replies and unclear updates from his supplier led to costly misunderstandings in his first order. To prevent these issues, set up a proactive communication workflow from the start. Here are key practices to ensure smooth communication:

Single Contact Person: Have the supplier designate a dedicated account manager or representative for your order. This person should coordinate internally with their production, QC, and logistics teams on your behalf. Dealing with one well-informed contact (rather than being passed around) reduces confusion. Make sure this person understands your project details and is fluent in your language (usually English for international trade).

Regular Visual Updates: Schedule checkpoints for updates during production. For example, ask the supplier to send photos or short videos when the tiles begin production, during glazing or printing, after kiln firing, and when packaging or loading the container. These visual updates let you monitor progress and catch any visible issues early, and they give you peace of mind that things are on track. It also holds the supplier accountable to follow the agreed timeline and quality.

Written Confirmation of Key Points: Verbal chats or instant messages are convenient, but always follow up important discussions in writing (email is best). If you decide on a change (like a different carton design or a slight tweak in color), have the supplier confirm it by email. Likewise, send formal emails for technical confirmations, order changes, and inspection reports. This creates a paper trail so everyone knows exactly what was agreed. It prevents the “I thought you said X” type of confusion later on.

Set Response Expectations: Clearly communicate your expectations for responsiveness. Let the supplier know you appreciate prompt replies and set a reasonable standard (for instance, expect acknowledgment of emails within 24 hours). Good suppliers will often have no issue with this, and by voicing it early, you highlight that communication speed is important to you. Additionally, plan for time zone differences – agree on a compatible time for any live calls/online meetings if needed, and use a mutually accessible platform (Email for formal communication, plus perhaps WeChat/WhatsApp for quick updates, but not for final decisions). By establishing these norms, you avoid the number one complaint Victor and many others have: being left in the dark when you need answers fast.

By managing the communication process actively, you not only reduce frustrations but also build a stronger relationship with the supplier. When a supplier sees that you are organized and attentive, they are more likely to prioritize your orders and deliver reliably.

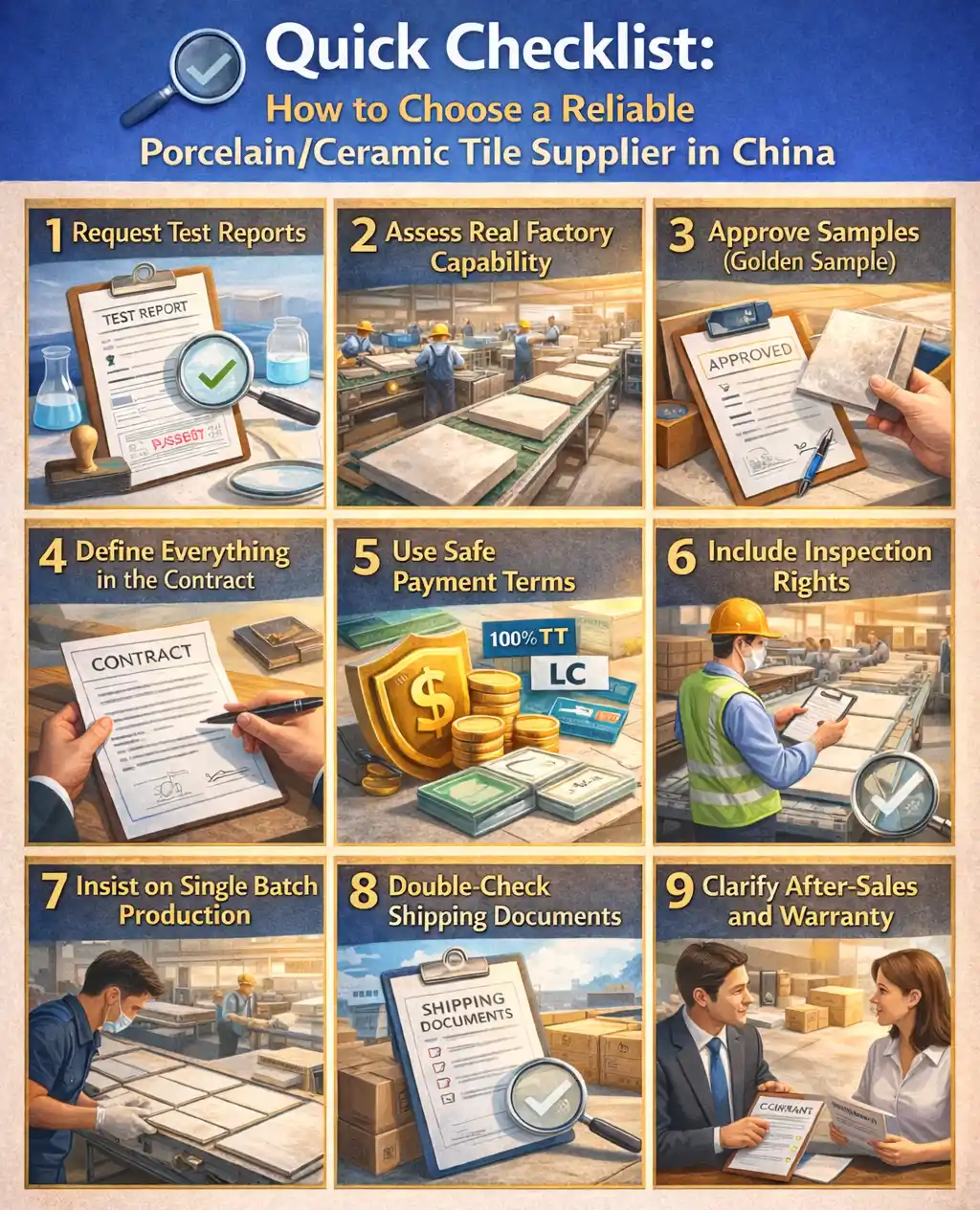

Quick Checklist: How to Choose a Reliable Porcelain/Ceramic Tile Supplier in China

Verify Legal and Quality Credentials: Ensure the supplier is a legitimate company. Ask for their business license and check they have at least basic quality certifications like ISO 9001. If your market requires specific compliance (e.g. CE marking for Europe), confirm they have those certificates for their tiles.

1. Request Test Reports: Always obtain recent test reports for the tiles, issued by an independent lab (such as SGS or Intertek). These reports should show key parameters (water absorption, strength, abrasion etc.) meeting international standards (like ISO 10545 or EN 14411 tests). Up-to-date reports prove the supplier’s claims about quality are backed by data.

2. Assess Real Factory Capability: Don’t just rely on glossy brochures. If you can’t visit in person, do a video call tour of the factory or have a third-party inspection company verify the facility. A reliable supplier will be transparent and even provide live video of their production line, inventory, and QA processes to show they can fulfill your order.

3.Approve Samples (Golden Sample): Never skip sampling. Get a production sample of the exact tile lot if possible and approve it. Then have both you and the supplier keep a copy of this approved “golden sample,” signed or sealed. This sample is your reference to ensure the mass-produced tiles match what you agreed on.

4. Define Everything in the Contract: Put all important details in writing via a purchase contract or agreement. List the product specs, technical standards, inspection terms, delivery timeline, and payment terms clearly. A good contract makes expectations explicit for both parties and will include what happens if specs or timelines are not met.

5. Use Safe Payment Terms: Structure payments in stages to minimize risk. A common method is 30% deposit and 70% after quality inspection (before shipment or against shipping documents). This way the supplier has incentive to produce good quality (to get the remaining payment), and you don’t pay all money upfront. Avoid any supplier who demands full payment before production – that’s a red flag.

6. Include Inspection Rights: Make sure you have the right to do a pre-shipment inspection (PSI), either by yourself or an independent inspector. This should be mentioned in your agreement. Knowing that an inspection will happen motivates the supplier to maintain quality, and it gives you a chance to catch any problems before the tiles leave the factory.

7. Insist on Single Batch Production: For consistency, your order should ideally be produced in one batch (one continuous production run). Confirm with the supplier that all tiles for your order will be from the same lot and have the same shade number. Mixed batches can lead to color or caliber differences, so a reliable supplier will plan production accordingly for your order size.

8. Double-Check Shipping Documents: A trustworthy supplier will prepare accurate shipping documents. Before the ship sails, ask for copies of the bill of lading, packing list, commercial invoice, and any certificates (origin, quality, etc.) to verify details. This prevents issues at customs – for example, ensuring the product description, quantities, and weights match exactly between the goods and the paperwork.

9. Clarify After-Sales and Warranty: Discuss what happens if there’s a quality issue discovered after you receive the tiles. A reliable supplier won’t disappear after shipping. They should agree on a reasonable claim period (e.g. within 2 weeks of delivery) where you can report problems like excessive breakage or defects not caught earlier. And there should be a plan – whether it’s a refund, replacement, or credit – to resolve legitimate quality claims quickly.

10. Keep this checklist handy as you evaluate potential tile suppliers. It will help you filter out the unreliable ones and zero in on partners that are truly up to standard.

If you’re comparing tile suppliers in China and want clearer info on specs, test reports, lead times, and inspection points, you can email Miller at miller@kingsuntile.com for practical input and sourcing support.

FAQ

Q: What certifications should a China tile supplier provide?

A: They should provide proof of compliance with your market’s standards and evidence of their quality control. Look for an ISO 9001 quality management certificate, any required product safety certifications (for example, CE for European countries), and recent test reports from reputable labs (like SGS or Intertek) showing the tiles meet key standards (such as water absorption and strength tests per ISO/EN/ASTM).

Q: What is a realistic lead time for wholesale porcelain tiles from China?

A: Generally about 20–30 days of production after you pay the deposit for a standard order. This timeline can vary slightly depending on the factory’s schedule and the specific product, but roughly one month is typical for manufacturing common porcelain tiles before they’re ready to ship.

Q: How to avoid shade variation in porcelain tiles?

A: The best way is to ensure all tiles in your order come from the same production batch. Insist on strict batch/lot control so the whole order is fired under the same conditions. It’s also wise to seal an approved golden sample as the color reference, specify acceptable color variation in your contract, and do a pre-shipment inspection checking random tiles from different boxes for color consistency.

Q: Factory vs trading company: which is safer for first order?

A: For your first import, a reputable trading company is often the safer choice. They usually offer more support – like handling logistics, combining different tile types, and lower quantity requirements – which reduces complexity and risk for you. Once you gain experience and trust, you could consider buying directly from a factory to potentially get better pricing, but initially the service and flexibility of a trading company can be very valuable.

Q: What inspection points matter most for ceramic tile shipments?

A: Key inspection points include dimensional accuracy (tiles should meet the size/thickness specs and be perfectly square), surface quality (no cracks, chips, or glaze defects, and consistent color/shade across pieces), and proper packaging (strong cartons with correct labels including lot number). It’s also important to verify the total quantity and that all tiles are from the same batch to ensure uniformity in your shipment.

-

China tile supplier: See our quick list of 10 leading ceramic tile manufacturers in China to compare strengths and choose faster. ↩

-

Learn how a golden sample can help ensure product consistency and quality. ↩

-

Find a comprehensive checklist to ensure your tiles meet quality standards before shipping. ↩