Sintered stone is an ultra-compact slab made by fusing natural minerals under 1,200 °C and 15,000-ton pressure. The process creates a dense, non-porous1 surface that outperforms natural stone and engineered quartz. Its headline advantages are:

- Stain resistant: near-zero porosity stops wine, oil, and coffee from soaking in.

- Heat proof: handles 300 °C+ cookware without scorching or cracking.

- Scratch proof: Mohs 6-7 hardness shrugs off knife and utensil marks.

- Chip & impact tough: dense core resists everyday knocks and edge damage.

- UV stable: colors stay true in direct sunlight, perfect for outdoor use.

- Eco-friendly: resin-free, low-VOC, often made with recycled minerals.

- Low maintenance: never needs sealing—just wipe with soap and water.

Distributors and buyers often face a tough problem: surfaces that stain, chip, or wear out can ruin projects and reputations. I’m Miller from Kingsun, and I’ve watched sintered stone solve those issues firsthand. In this article, I’ll break down each advantage so you can decide if it’s the right material for your next project.

🔍 Watch this real-life test of sintered stone's performance: stain resistance, heat resistance, and scratch resistance — all demonstrated in one short video.

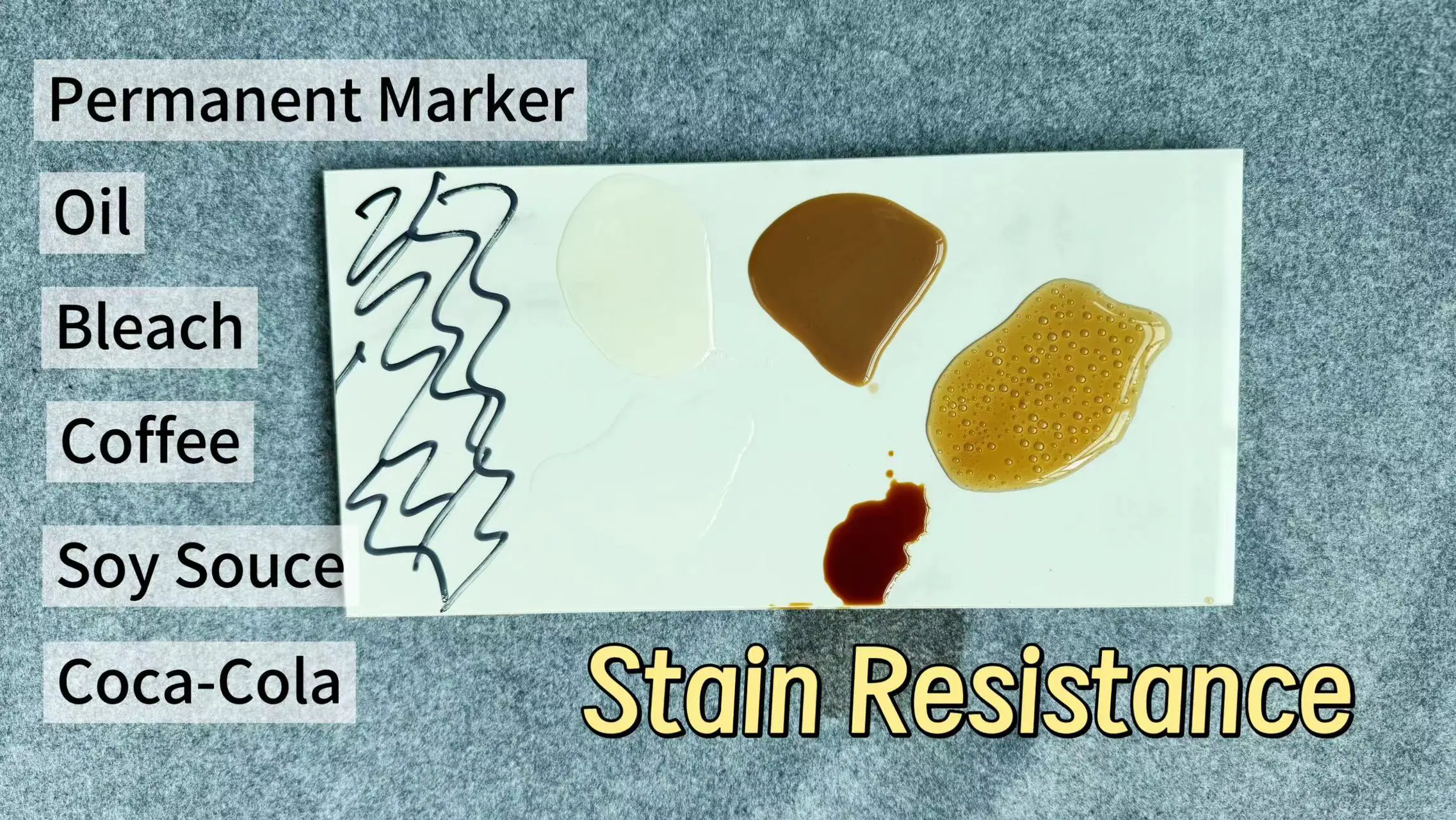

Is sintered stone stain resistant2?

- Yes. Sintered stone is highly stain resistant due to its ultra-low porosity. Liquids and dyes can’t easily penetrate its surface, so most spills (like wine, coffee, or oil) wipe off without leaving a mark. This non-porous material resists staining far better than natural stone, keeping surfaces looking new.

Dive Deeper:

Non-Porous, Non-Stick Surface

Sintered stone is engineered to be virtually non-porous, meaning it hardly absorbs any moisture or liquids. In our Kingsun factory tests, we measured water absorption rates below 0.1% – in some cases as low as 0.03%. To put that in perspective, these slabs are almost waterproof, so spills cannot seep in. This is a game changer for stain resistance. Liquids like red wine, soy sauce, or coffee remain on the surface instead of soaking in, allowing you to simply wipe them away. Because sintered stone is so dense and non-porous, it doesn’t “hold onto” colors or oils. Even chemicals and cleaners don’t leave spots or bleach marks – a stark contrast to some natural stones that can be discolored by harsh substances. In practice, this means a sintered stone countertop can be white or light-colored and still resist the dreaded stains that would plague a white marble or unsealed granite top.

Real-World Stain Performance

From my experience working with distributors, this stain resistance holds up in real kitchens and projects. I recall a client spill test: we left dark soy sauce and red wine on a pale sintered stone sample for hours. After a simple wipe with a cloth and mild cleaner, the surface was as good as new – no shadow or discoloration at all. In contrast, a piece of natural marble exposed to the same spills got visibly stained and needed abrasive cleaning. Sintered stone’s immunity to stains also reduces maintenance: no sealing is required (unlike marble or certain granite that demand periodic sealants to block stains). The surface’s smooth, non-porous nature even reduces the need for strong detergents; mild soap and water suffice for cleanup, because grime doesn’t cling stubbornly. This not only keeps the material looking pristine, but also saves time and avoids chemical cleaners, which ties into environmental benefits.

Comparison of Porosity and Stain Risk

To understand why sintered stone resists stains so well, it helps to compare porosity among materials:

| Material | Typical Water Absorption | Sealing Needed? | Stain Resistance |

|---|---|---|---|

| Sintered Stone | ≤0.1% (often \~0.03%) | No | Excellent – spills don’t penetrate |

| Porcelain Tile | ≤0.5% | No (glazed) | Excellent – very low porosity |

| Engineered Quartz | \~0% (non-porous) | No | Very good – resists most stains |

| Natural Marble | \~0.2–0.5% | Yes (regularly) | Poor – easily stained/etched if unsealed |

As shown above, sintered stone has nearly zero water absorption, even outperforming standard porcelain tiles in density. Unlike marble, which is porous and can soak up colored liquids (leading to stains or dark spots), sintered stone simply does not let the stain in. In fact, because marble is composed of calcite, it’s also vulnerable to acids – even a bit of lemon juice or vinegar can chemically etch and discolor marble. Sintered stone has no such weakness; it’s chemically stable and acid-resistant, so you won’t get those dull etched rings from acidic foods. For buyers who run busy showrooms or projects, this means less worry: they can confidently offer bright, elegant sintered stone surfaces to customers without the “what if it stains?” anxiety. It’s a reliable selling point that the material will maintain its appearance in the long run.

Is sintered stone durable?

- Yes. Sintered stone is exceptionally durable. It’s an ultra-compact, hard-wearing surface that resists scratches, impacts, and heavy use without damage. Its high-density, solid structure means it won’t crack or wear easily, even in high-traffic areas. This long-term durability makes it ideal for both commercial and residential projects.

Dive Deeper:

Engineered for Strength

Sintered stone is often described as “nearly indestructible”, and there’s good reason for that. During manufacturing, we press the mineral powders under extremely high pressure (far higher than traditional ceramic tile), then fire the slab at \~1200°C. This process fuses the particles into a solid, uniform mass. The result is a dense and tough slab that can handle significant force. For instance, sintered stone’s flexural strength (ability to resist bending or cracking under load) is often above 50 MPa, comparable to or better than granite. Its surface hardness ranks around 6 to 7 on the Mohs scale – about as hard as quartz and much harder than steel or ordinary knife blades. In practical terms, this means the material is highly resistant to scratches, abrasion, and impact. If you drop a heavy pan or even hit the surface, sintered stone is less likely to chip or crack than many natural stones or standard porcelain tiles.

Longevity in High-Use Environments

For high-traffic flooring, exterior facades, or busy kitchens, durability3 isn’t just a nice-to-have; it’s essential. Sintered stone shines in these scenarios. It’s been successfully used in commercial malls and building exteriors where it faces constant foot traffic, UV exposure, and temperature changes. Unlike some materials, it won’t fade or weaken under UV rays – a huge plus for outdoor use in sunny climates. I’ve had distributors in tropical regions ask if sintered stone can handle heat and humidity outdoors; the answer is yes, it’s completely UV-stable and water-resistant, so it doesn’t warp or discolor even in extreme weather. Additionally, the material’s hardness means everyday wear and tear won’t create visible scratches or wear patterns. Floors remain glossy and countertops retain their polish even after years of use. Sintered stone also resists thermal shock (sudden temperature changes) better than natural granite or marble, which can crack if exposed to heat and cold cycles. This stability is why some call it a “forever” material – it’s built to last for decades with minimal maintenance. For businesses, that longevity translates to satisfied end customers and fewer warranty claims or callbacks.

Impact and Load Resistance

A critical aspect of durability is how a material handles impacts and heavy loads. Sintered stone’s dense structure gives it excellent impact resistance. Dropping heavy cookware or tools on a sintered countertop usually won’t cause any damage – something I’ve demonstrated to skeptical buyers by literally pounding a sample with a hammer. (The hammer left no mark on the slab, but my workbench took a beating!) The material’s hardness also means it’s highly resistant to dents or dings. Compare this to a softer surface like wood or a resin countertop, which can dent under pressure, or to natural marble, which might crack if struck hard. Moreover, sintered stone can handle weight – you can confidently install it as large countertops or table tops; properly supported, it won’t sag or break even with people sitting or standing on it. This strength has even enabled new applications: I’ve seen sintered stone used structurally for shelving and furniture panels where durability is paramount. Overall, the answer to durability is clear: sintered stone is designed to endure. It provides peace of mind that surfaces will remain intact and attractive through years of heavy use, a key advantage that sets it apart from less robust materials.

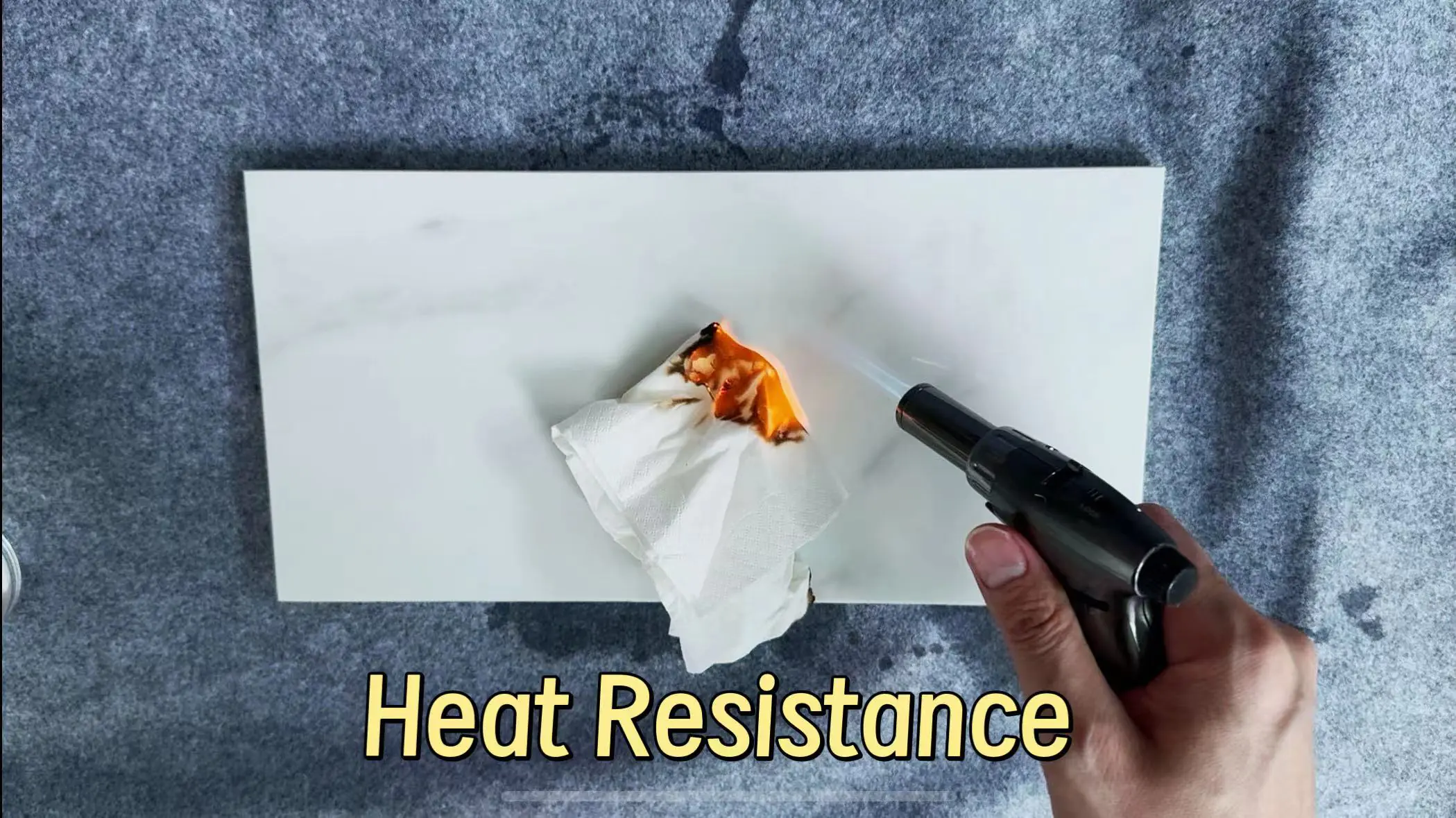

Is sintered stone heat resistant4?

- Yes. Sintered stone is highly heat resistant. You can place hot cookware or pans directly on it without burning or melting the surface. Unlike quartz (which can scorch around 150°C), sintered stone withstands extreme temperatures (300°C+ easily, even up to \~1200°C in some tests) without cracking or discoloration. This makes it ideal for kitchens, fireplaces, and sunny outdoor installations.

Dive Deeper:

Withstanding Extreme Temperatures

Sintered stone is forged in fire – literally. Because it’s created at over 1200°C in a kiln, the finished slab has already survived temperatures far beyond anything it will encounter in normal use. This gives it an inherent tolerance to heat that far exceeds materials like engineered quartz or solid surface countertops. In practical terms, you can take a pot of boiling water or a hot cast-iron skillet and set it directly on a sintered stone countertop without fear of scorching. The surface won’t burn, char, or emit smoke because there are no resins or plastics in it (it’s 100% minerals). Quartz countertops, by comparison, contain around 7-10% resin binders that begin to degrade and discolor at roughly 150°C (302°F). Sintered stone has no such vulnerability – it can comfortably handle 300°C (572°F) and above with no damage. In fact, laboratory tests and some manufacturers claim sintered stone can resist heat up to \~1200°C, which is essentially red-hot metal temperatures. While you’d rarely expose a surface to that extreme in a home, it’s reassuring to know the material itself will not combust or melt even under direct flame.

Real Kitchen Use: Hot Pots and Thermal Shock

In daily use, “heat resistance” often comes down to whether you need a trivet. With sintered stone, I confidently tell clients that trivets are optional for moderate heat. Placing a 200°C baking dish or a tray straight from the oven on the counter won’t faze it. I’ve done demonstrations where we put a red-hot metal ball on a sintered slab and saw no crack or mark – a party trick that always impresses chefs and kitchen fabricators. Thermal shock (sudden temperature change) is one area to be mindful of: while sintered stone itself tolerates heat, any material can suffer if, say, a very hot object is put on an extremely cold surface quickly. However, sintered stone still outperforms natural stones here. Granite or marble might crack with a rapid temperature swing (they have internal stresses and weaker bonds), whereas sintered stone’s engineered uniformity helps it dissipate thermal stress better. As a best practice, I advise using trivets for extreme heat (like a cast iron straight from a 500°F/260°C oven) just to be safe – not because the stone will burn, but to avoid any rare thermal shock scenario.

Heat vs. Other Materials

It’s useful to compare how sintered stone stacks up against other common surfaces when it comes to heat:

- Engineered Quartz: Begins to scorch or discolor at \~150°C. Prolonged or repeated exposure to hot pans can leave brown burn marks or cause the resin to deform. Quartz cannot handle open flame or very high heat – it will crack or even emit odors if burnt. Sintered stone handily beats quartz here; you won’t ruin it with a hot pan that would have damaged a quartz top.

- Natural Granite: Generally more heat-resistant than quartz (contains no resin). Granite can usually take around 200–250°C before issues. However, rapid heat changes can crack granite, and its polished surface might get dull spots from thermal stress. Sintered stone’s advantage is its lack of micro-cracks or veins that could propagate a crack – it’s more uniform, so it’s less likely to break from heat. Also, granite countertops often still recommend trivets to avoid any risk.

- Marble: Even worse with heat – around 150–180°C tolerance. Marble can discolor or scorch, and more commonly, it can suffer thermal etching (the calcite reacts or crystals expand). Hot items can leave a rough spot on marble. Clearly, sintered stone is a safer bet for any hot usage.

- Ceramic/Porcelain Tile: Similar composition to sintered stone, porcelain is also very heat resistant (kiln-fired). Individual tiles handle heat fine, but the difference is usually in thickness and installation. Thin porcelain slabs can heat up and cool down quickly, which might make them a bit more prone to thermal shock if not properly supported. Sintered stone slabs, often thicker and larger format, have the bulk to absorb heat evenly.

To sum up, sintered stone won’t get burn rings or scorch marks. This is a huge relief in busy kitchens – one less thing to worry about. I often use the slogan that sintered stone lets you “put the pan down and relax.” It’s built to thrive where others might crack under the pressure (or the heat, in this case). For outdoor kitchens and barbecue areas, this property is especially valuable: you can incorporate sintered stone near grills or as a countertop that sees direct sun and heat, and it will stay intact and looking great.

Is sintered stone scratch resistant5?

- Yes. Sintered stone is extremely scratch resistant. With a Mohs hardness of about 6–7, it’s harder than steel utensils, so knives and everyday objects won’t easily scratch it. You can even cut food directly on a sintered stone countertop without damaging the surface (though using a cutting board is advised to protect your knives!). This means the surface stays smooth and free of scratch marks even after heavy use.

Dive Deeper:

Hardness that Rivals Natural Stone

One of sintered stone’s standout qualities is its high hardness. On the Mohs scale (which geologists use to measure mineral hardness), sintered stone typically falls around 6 to 7. For context, stainless steel knives are about Mohs 5.5, and quartz (the mineral) is Mohs 7. This means sintered stone is about as hard as quartz and significantly harder than common metals and tools. In practical terms, the average kitchen knife cannot scratch a sintered stone slab – the blade would get dulled before the countertop ever got a scratch. I often demonstrate this to clients by taking a steel key or a knife and trying to mar a sample piece; I end up with metal marks on the stone (which wipe off) but no scratch in the actual surface. The stone’s hardness makes it highly resistant to abrasions – whether it’s a sliding ceramic dish, a dropped fork, or a pet’s claws, sintered stone won’t easily show wear. This is a huge advantage for high-traffic surfaces like kitchen islands, dining tables, or flooring in public spaces.

Cutting and Cooking Directly on the Surface

Many marketing claims sound too good to be true, but here’s one I can confirm from experience: you can chop vegetables directly on sintered stone without damaging it. We actually have a video at Kingsun where I cut and even use a cleaver on a sintered stone slab – there were no scratches. (Our joke is that the poor knives took the brunt of it; a very hard surface will dull your knives over time, which is why using a cutting board is still a good idea, but for the surface itself there’s no harm.) Some adventurous chefs even use a blowtorch for searing food directly on sintered stone because it’s both heat- and scratch-proof – try that on a laminate or resin counter and you’d have a disaster! The ability to handle direct cutting means sintered stone is virtually knife-proof in normal use. It’s reassuring for end users who might otherwise be paranoid about using their countertops fully. No special chopping pads or fear of scratching if someone drags a pot – it’s a forgiving worktop.

Abrasion and Wear Resistance

Scratch resistance isn’t just about one-time cuts; it’s also about resisting wear over years. Some countertops develop a patina of micro-scratches (tiny, fine lines that accumulate and make the surface look dull). Sintered stone’s hardness prevents most of that. For example, polished sintered stone slabs tend to maintain their gloss since there are no soft components to get microscopically abraded by dust or grit. This is why many sintered stone products are used in flooring – even under foot traffic with dirt, the tiles don’t wear down easily. They often achieve top scores in abrasion tests (like PEI ratings, where sintered stone qualifies for heavy commercial use). I’ve walked through hotel lobbies using large sintered stone tiles; even after a few years, you don’t see worn paths on the floor like you might with softer marble. The consistent scratch resistance across the surface also means you won’t get those odd shiny/dull patches that some engineered surfaces show after uneven use. Every inch of sintered stone is just as tough. In summary, whether it’s the occasional slip of a knife, a heavy appliance being moved, or just the cumulative effect of daily life, sintered stone stands up to scratching forces admirably. For distributors, this means fewer complaints about “surface quality degrading,” and for end users, it means peace of mind and lasting beauty.

Is sintered stone easy to chip?

- No. Sintered stone is not easy to chip under normal use. Its dense, strong composition makes it highly resistant to chipping or cracking from everyday impacts. The edges of sintered stone slabs are very robust – they won’t chip if you bump them lightly or set heavy dishes on them. Only extreme force or sharp impact (like dropping a cast-iron pan on a thin, unprotected corner) might cause a chip. With proper handling and installation, chipping is rarely an issue, making sintered stone a reliable choice for long-lasting surfaces.

Dive Deeper:

Tough Edges and Corners

One of the key advantages of sintered stone is that its strength isn’t just on the surface – it runs through the whole slab. This means edges and corners, which are typically the most vulnerable points on any countertop or tile, are quite strong and chip-resistant. In my experience, a well-fabricated sintered stone edge (say a straight polished edge on a 12 mm slab) can withstand everyday knocks that might chip a natural marble or even a ceramic tile. For example, accidentally banging a coffee mug or a wine bottle against the edge typically leaves the mug or bottle worse off than the counter! The dense sintered stone just doesn’t flake the way a more brittle material would. It’s also common to reinforce or design edges with a slight bevel (arris) to further prevent chipping; our Kingsun slabs come with recommendations for fabricators on edge profiles that maximize durability. When those guidelines are followed, chipping is exceedingly rare in normal use.

Comparing Brittleness: Porcelain/Quartz vs. Sintered

It’s true that any very hard material can have some brittleness – hardness often means less flex (think of glass: very hard, but can shatter). Sintered stone, however, strikes a balance by being hard yet still having some internal strength and flexibility thanks to its manufacturing process. Let’s compare:

- Porcelain Tile/Slabs: Traditional porcelain can chip if something hits an edge, especially if the tile is thin. I’ve heard concerns from installers that “porcelain is brittle.” Sintered stone is essentially an advanced form of porcelain, but usually thicker and made with improved particle bonding. This gives it a notch up in toughness. Still, if you took a hammer to the edge of a sintered stone slab with enough force, yes, you could chip it. But the same impact would likely shatter a standard porcelain tile.

- Engineered Quartz: Quartz countertops have a bit of polymer resin, which can actually make them slightly more forgiving on minor impacts (a tiny amount of “give”). Sintered stone lacks resin, so it is more purely stone-like. In practice, I’ve found both quartz and sintered stone resist chips from everyday incidents like dropping a plate on the counter. However, there is anecdotal evidence that sintered stone edges might chip slightly more easily than quartz if hit just right with a sharp, heavy object, simply because quartz’s resin gives it a touch of cushion. The difference is not big – and unlike quartz, if a sintered stone does chip, it’s usually just a small nick that doesn’t propagate or “run.”

- Natural Stone (Granite/Marble): Marble is quite soft, so edges round off or chip relatively easily (even a heavy glass set down can chip a marble edge). Granite is harder, but depending on the grain can chip too. Sintered stone generally outperforms marble by a wide margin (marble corners are infamously easy to ding), and it’s on par with high-quality granite for chipping resistance.

The bottom line I share with clients: treat it with normal care and you’ll be fine. Don’t deliberately whack the edges with a hammer or drop a cast-iron sink onto it during install – but those are things that could damage almost any material. In real-world use, sintered stone edges stay intact. And if an edge does get a tiny chip (say, a moving company smacks a countertop edge with a metal fridge component – I’ve seen it happen), it can usually be repaired or smoothed out because the color and pattern go through the material. I recall one case where an installer chipped a corner during transport; they were able to slightly round the corner and re-polish it, and it was virtually undetectable afterward. This is much harder to do with, say, a patterned quartz where the inner composition is different from the surface.

Best Practices to Avoid Chips

From the factory perspective, we always advise a few best practices to minimize any chipping risk:

- Use proper edge profiles (a small eased edge or bevel can prevent sharp edges that are more prone to chipping).

- During installation, ensure the slabs are fully supported – an unsupported overhang that gets leaned on could crack or chip.

- For thin sintered stone panels (like 6 mm used on walls or cabinet fronts), handle with care just as you would large glass – once bonded to a substrate, they’re strong, but in transit they could crack if bent.

- In daily use, avoid direct hammering or dropping extremely heavy objects right on edges (common sense for any countertop).

Following these, we’ve had excellent feedback that chipping is basically a non-issue. In summary, sintered stone is tough, not fragile. You’re not going to find little chips around your countertop from normal activities. This durability at the edges gives confidence to both installers and end users that the product is built for real life.

Is sintered stone environmentally friendly?

- Yes. Sintered stone is considered an environmentally friendly surface option. It’s made from natural minerals with no synthetic resins or harmful binders. Many sintered stones include recycled materials6 and can be recycled themselves at end-of-life. The production process uses heat and pressure but relatively few chemicals, resulting in a product that’s VOC-free, food-safe, and sustainable for green building projects. Its long lifespan also means less replacement and waste over time.

Dive Deeper:

Natural Ingredients, No Harmful Additives

Sintered stone is essentially made of the same stuff as rocks and clay – just in a controlled, engineered form. The typical ingredients are natural minerals: things like quartz sand, feldspar, clay, and mineral oxides for coloring. What’s notably absent is any kind of polymer resin or glue. This sets sintered stone apart from engineered quartz, which uses plastic resins, and from solid-surface countertops, which are basically plastics. Because sintered stone has no resin and no volatile compounds, it doesn’t off-gas any chemicals into your home or the environment. There are no formaldehyde, no VOCs, and no petroleum-based content in the slab. When we fire sintered stone in the kiln, the outcome is an inert piece of stone-like material. This inertness is a big plus environmentally: it means the slab won’t emit radon or any gaseous pollutants (something even natural granite is sometimes scrutinized for). It’s also food safe – since there are no harmful substances, you can place food directly on sintered stone surfaces without worry of contamination. I often point out to eco-conscious clients that sintered stone is about as close as you can get to replicating natural stone’s composition, but cleaner: no microplastics or chemical sealers needed.

Sustainable Production and Lifecycle

Manufacturing sintered stone does consume energy (the kilns run hot), but modern production lines in China and elsewhere often recapture heat energy and are improving efficiency all the time. Notably, recycled materials are commonly used in sintered stone production. For example, some of our Kingsun slabs incorporate recycled ceramic or glass powders, reducing the need for new raw mining. Since the material is uniform, you can use scraps and broken pieces from one batch as part of the raw mix for new slabs, cutting down on waste. Additionally, water used in polishing is usually recycled in the factory. Compared to quarrying huge blocks of marble (which scars mountains and uses lots of water and chemicals to process), producing sintered stone is a more controlled and potentially less destructive process. Many sintered stone brands have environmental certifications and align with green building standards. The carbon footprint per square foot often compares favorably to that of cement or ceramic tile production, especially when factoring in the longevity (because you won’t be replacing it frequently).

Longevity = Less Waste

One often overlooked aspect of sustainability is how long a material lasts. Sintered stone’s durability and low maintenance contribute to its eco-friendliness. Why? Because if you install a sintered stone countertop or facade, you likely won’t need to replace it for decades – thus reducing consumption of additional materials over time. A cheap laminate counter, by contrast, might be thrown in a landfill and replaced multiple times in the same span. Sintered stone is also fully recyclable in the sense that, at end of life, it can be crushed and reused as construction aggregate or even potentially re-sintered into new products. Since it’s basically stone and clay, disposing of it is like disposing of ceramic or brick – no toxins leach out, and crushed up, it’s inert fill. Some experts note that sintered stone can be returned “to the earth” much more harmlessly than something like a plastic-based countertop.

Green Credentials

A quick checklist of green credentials for sintered stone:

- Low/No Emissions: Certified for zero VOC emissions (often GREENGUARD Gold or similar certifications are obtained by manufacturers).

- Recycled Content: Many products include 20% or more recycled content (varies by brand). This repurposes waste from other industries.

- Natural Material: Composed of abundant, natural minerals; no scarce or endangered resources.

- No Sealers Needed: Because it’s non-porous, you don’t need to apply chemical sealants or harsh cleaners, which is healthier for both users and the environment (less chemical runoff).

- Sustainable Design: Qualifies for LEED points in categories like recycled content and low-emitting materials.

- Long Life: Reduces frequency of renovations/replacements, aligning with sustainable building practices.

From my perspective at Kingsun, embracing sintered stone has also been part of our journey towards greener manufacturing. We’ve invested in energy-efficient kilns and dust collection to ensure the process is as clean as possible. And international buyers appreciate that they can market sintered stone as an eco-friendly choice to their customers – it’s not just another pretty surface, it’s one that aligns with modern values of sustainability. In summary, sintered stone checks the eco box: it’s green from start to finish, combining natural composition with thoughtful production and a long, useful life.

Advantages of Sintered Stone Compared to Porcelain Tile, Quartz, and Natural Marble?

- Sintered stone offers unique advantages over porcelain tile, quartz, and natural marble. It combines the best qualities of each while eliminating many of their drawbacks. For example, sintered stone is more heat and UV resistant than quartz, stronger and larger-format than standard porcelain tile, and far more stain/scratch resistant than marble. This means sintered stone provides a more durable, low-maintenance, and versatile surface option overall, ideal for both indoor and outdoor use.

Dive Deeper:

To make the comparison clear, let’s break down the advantages of sintered stone vs each material:

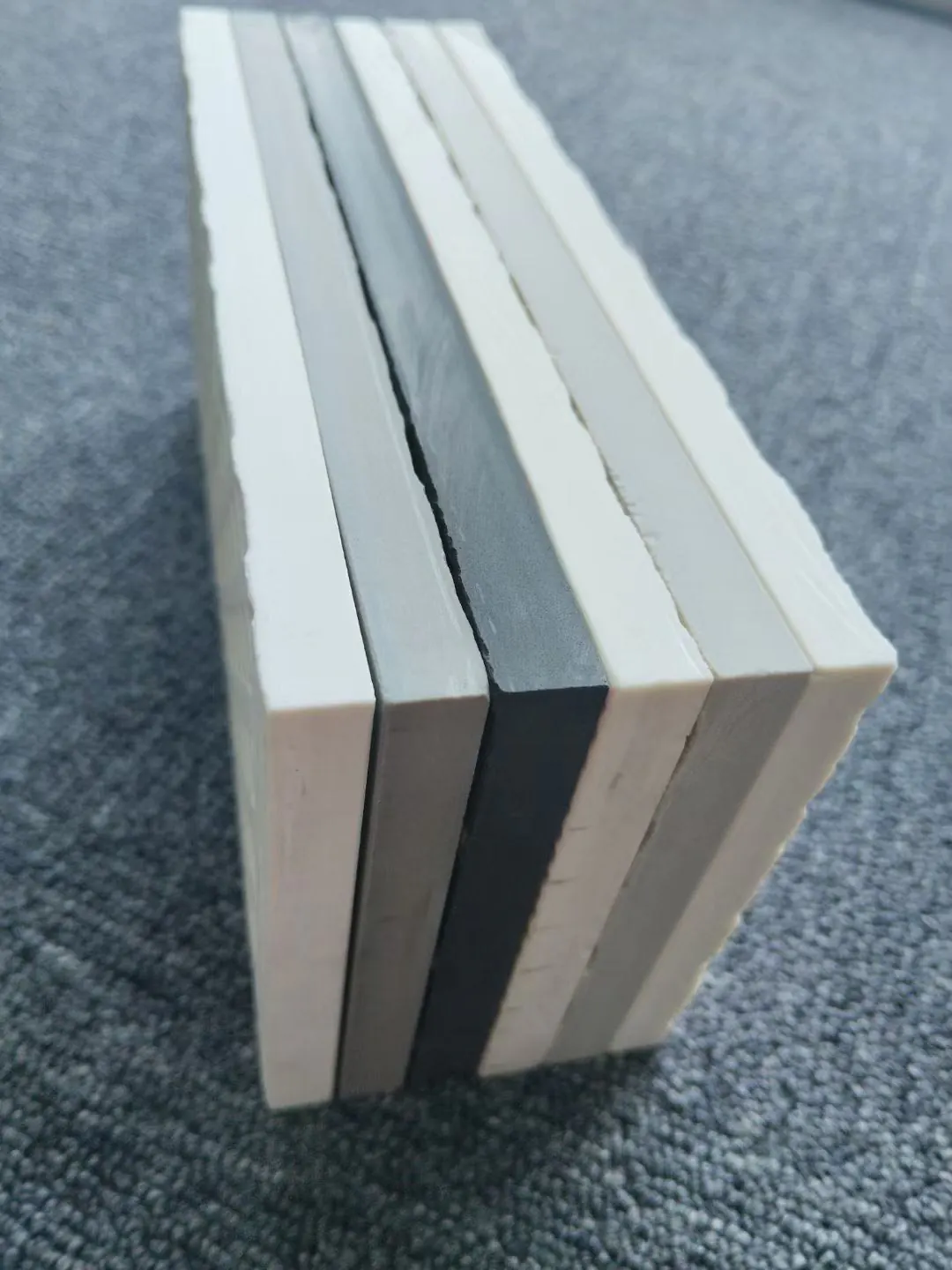

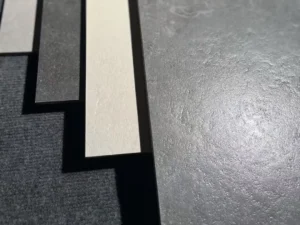

Sintered Stone vs Porcelain Tile

Porcelain tile and sintered stone are actually close cousins – both are kiln-fired ceramic materials. The key difference lies in format and strength. Sintered stone typically comes in large slabs (commonly 1.2×2.4m, 1.6×3.2m, etc.), whereas porcelain tiles are often smaller (e.g. 60×60 cm) or if large-format, usually thinner. The large slab format of sintered stone means you can cover countertops, big wall areas or floors with minimal joints/seams, giving a more seamless look that’s hard to achieve with regular tiles. From an installation perspective, one sintered slab could replace many tiles, reducing grout lines and potential weak points.

In terms of performance, both materials are non-porous and stain resistant. However, sintered stone slabs are usually made under even higher pressure (some use 15,000+ ton presses) and with advanced techniques that yield higher density and strength than standard porcelain. This can translate to better impact resistance and load-bearing capacity. Porcelain tiles, especially if thin, can be a bit brittle and may crack if something heavy drops on them or if there’s not perfect support. Sintered stone’s thickness (often 12 mm or more for counters) and fabrication make it less prone to cracking or chipping in use. Another advantage is through-body composition: many sintered stones are the same color/pattern throughout the thickness, so if an edge is exposed or a slight chip occurs, it’s less noticeable. Traditional porcelain tiles often have a glazed top and different color body – if they chip, you see the base color.

From a design standpoint, sintered stone slabs can have very realistic stone patterns and even continuous vein designs (bookmatching, etc.), giving you the luxury look of marble with the performance of porcelain. Porcelain tiles do come in many designs too, but achieving something like a large uninterrupted stretch of bookmatched veining is easier with sintered slabs. Porcelain’s advantage might be cost – porcelain tiles are generally cheaper and have a long track record. But when you consider installation (lots of tiles vs one slab) and maintenance (grout cleaning), sintered stone often ends up being a superior solution for high-end applications. Essentially, sintered stone takes porcelain to the next level: bigger, stronger, and more luxurious.

Sintered Stone vs Quartz (Engineered Stone)

Engineered quartz has been a dominant countertop material for years, so this comparison is crucial. Durability: Both quartz and sintered stone are very durable, but sintered stone has the edge in heat and UV resistance. Quartz, as mentioned, can scorch or discolor with heat and will fade/yellow in outdoor sun exposure over time. Sintered stone is completely heat proof for normal usage (you can put hot pans on it) and UV-stable, so it’s suitable for outdoor kitchens, facades, BBQ areas – places you’d never use quartz.

Scratch resistance: Both are hard, but sintered stone is often just a bit harder (Mohs 6-7) whereas quartz is around Mohs 5-6. This means sharp utensils may scratch quartz slightly more easily. I’ve seen polished quartz countertops develop faint scratches over time, whereas sintered stone tends to stay scratch-free due to its ceramic-like surface hardness.

Stain resistance: Quartz and sintered stone are both non-porous and highly stain-resistant. However, quartz can be sensitive to certain chemicals – for example, strong solvents or high-pH cleaners might discolor the resin in quartz, and prolonged UV exposure can cause yellowing. Sintered stone is chemically inert and doesn’t have those vulnerabilities. You also never have to worry about resin pooling or discoloration on a hot surface with sintered stone (an issue that sometimes happens with cheaper quartz near cooktops).

Aesthetics: Quartz offers lots of colors and is great at mimicking stones like marble, but sintered stone is arguably even better at it. Some sintered stone products have high-definition natural patterns and through-body veining that quartz often can’t achieve. Quartz slabs are limited by their resin binding – for instance, you won’t get the same ultra-matte or textured finishes that sintered stone can have (like a honed, leathered ceramic feel). Sintered stone can come in various finishes including polished, matte, satin, textured, etc., giving more design versatility. Also, because sintered stone can be produced in very large slabs, you can cover big surfaces without seams where a quartz might be limited by slab size or need a seam.

Environmental/Health: We touched on this – quartz has \~7-10% resin and isn’t fireproof; if it burns, it can release fumes. Sintered stone is entirely mineral and fireproof (A1 rated). Also, fabricating quartz can expose workers to crystalline silica dust – a health hazard if not properly controlled. Sintered stone is similar in that regard (also contains silica), but some brands market reduced-silica formulas or other safe handling features. In any case, end-users generally feel good knowing no petrochemicals are in their sintered stone.

Bottom line: Sintered stone is like quartz 2.0 – it addresses quartz’s weak spots (heat, UV, realism of design) while matching or exceeding its strengths (stain proof, consistency, strength). The only area quartz might win is familiarity and sometimes price; high-end quartz and sintered stone are often comparable in cost, though mass-market quartz can be cheaper. Still, for a client who wants the best performance, sintered stone usually comes out on top in this comparison.

Sintered Stone vs Natural Marble

This is a classic “innovation vs tradition” matchup. Stain & maintenance: Marble is gorgeous but infamously high-maintenance. It absorbs liquids, it stains, it etches with acids, and usually requires sealing and careful use. Sintered stone offers the look of marble without those headaches. For instance, a white Carrara marble countertop might stain from red wine or etch from lemon juice, whereas a sintered stone look-alike of Carrara will shrug those off with zero effect. You don’t need to seal sintered stone, ever, whereas marble typically needs sealing initially and re-sealing every so often.

Scratch & durability: Marble is relatively soft (Mohs \~3), so it scratches from even steel utensils or gritty dust. Sintered stone is much harder (Mohs \~6-7) and highly scratch resistant, so it keeps its polish and doesn’t get those scratches and dull spots that well-used marble gets. Marble is also prone to chipping and cracking; it has natural veins which can be weak points. Sintered stone is more uniformly strong (no random weak veins) and generally won’t crack unless under extreme stress. As a result, sintered stone can be used in thinner sections or larger spans that might risk a marble slab cracking under its own weight or under heat.

Heat & UV: Marble can handle some heat but can suffer thermal shock and definitely will discolor in outdoor conditions over years (white marbles can yellow, others can bleach out or get a rough surface from weather). Sintered stone is UV-proof and weatherproof – it’s being used on building exteriors in direct sun precisely because it won’t fade or deteriorate. So for outdoor luxury cladding or countertops, sintered is a better choice over marble if you want it to last.

Appearance: Here marble has a subjective edge – it’s real and unique. Every marble slab is one-of-a-kind with its natural veining and depth. Some clients simply must have that natural authenticity. Sintered stone imitates marble (often incredibly well), but a trained eye might tell the difference in certain cases, and the pattern, while very realistic, is manufactured (and repeatable). However, sintered stone can offer designs beyond what nature provides too – exotic patterns or consistent grain that you couldn’t get in real stone without imperfections. There’s also peace of mind: I often say sintered stone lets you enjoy the look of marble without living in fear of damaging it. That’s a huge advantage for restaurants, hotels, or just homeowners who don’t want to stress over their countertops. Designers appreciate that they can use light-colored or dramatic stone looks in high-traffic areas via sintered stone and not worry about the material failing.

Cost: High-end natural marble can be very expensive (and with considerable installation cost due to its weight and fragility). Sintered stone is generally more cost-stable and can even be cheaper than some prized marbles. There’s also less waste – marble slabs might have flaws to cut around; sintered stone is mostly all usable surface.

To synthesize these comparisons, here’s a quick table of key advantages of sintered stone vs each material:

| Aspect | Versus Porcelain Tile | Versus Quartz | Versus Marble |

|---|---|---|---|

| Size & Seamlessness | Larger slabs mean fewer seams (one piece can replace many tiles). | Similar slab sizes, but sintered stone can go thinner (for panels) or larger in some cases. | Large slabs mimic big marble pieces; can bookmatch without natural size limits. |

| Porosity & Stains | Both are non-porous; sintered stone equally stain-proof. | Both non-porous; sintered stone has no resin, so no chemical staining or discoloration. | Sintered stone is non-porous (no stains) vs marble porous (easily stained). |

| Scratch Hardness | Both very scratch resistant; sintered stone often thicker = surface can be refinished if needed. | Sintered stone \~Mohs 6-7 vs Quartz \~Mohs 5-6; sintered stone a bit more scratch resistant. | Sintered stone far harder (Mohs 6-7 vs \~3); marble scratches extremely easily by comparison. |

| Heat Resistance | Both fired ceramic – equally high heat resistance (far better than most materials). | Sintered stone is much more heat resistant (no resins to burn) – you can put hot pans, unlike quartz. | Sintered stone much more heat resistant; marble can scorch or crack, sintered stone won’t (good for kitchen use). |

| UV/Weather | Both are UV-stable; sintered stone slabs often used outdoors (facades). | Sintered stone is UV-proof (won’t fade); quartz yellows in UV, not for outdoors. | Sintered stone is UV/weather resistant; marble deteriorates/yellows outdoors over time. |

| Strength & Impact | Sintered stone slabs denser, often stronger (higher press load); porcelain tile thinner and can be brittle. | Both strong; sintered stone might chip slightly easier on edges than resinous quartz, but generally similar or better load strength. | Sintered stone far less brittle; no natural fissures. Marble can crack along veins; sintered is uniformly strong. |

| Maintenance | Both low maintenance (just clean, no sealing). Grout in porcelain tile is the only extra maintenance – not an issue with large sintered slabs. | Both low maintenance. Quartz doesn’t need sealing either. Sintered stone also doesn’t, and isn’t sensitive to cleaners as quartz can be. | Sintered stone is extremely low maintenance (no sealing, no worry about spills); marble requires constant care, sealing, and gentle cleaning. |

| Aesthetics | Sintered stone has premium marble/granite designs in large format, giving more luxurious look than small tiles. Tiles have grout lines and repeats. | Quartz has many designs but often more uniform; sintered stone can achieve more natural look with depth and varied texture. Both offer modern styles; sintered stone adds textures (matte, satin) that quartz can’t. | Marble is the real thing – unique beauty. Sintered stone provides that look with consistency (you can get slabs identical in pattern) and without imperfections. Some high-end marbles have depth that is hard to fully replicate, but sintered stone gets close enough for most, with huge practical gains. |

| Environmental | Both are eco-friendly ceramics. Sintered stone’s larger slabs might mean less material usage overall (one slab vs many tiles + cement). | Sintered stone has no resin (greener). Quartz production involves polymer resins and more restricted recycling. Sintered stone often contains recycled content. | Marble is natural but quarrying/transport is energy-heavy and it often needs chemical sealants. Sintered stone is manufactured but often more resource-efficient in use (less waste, lasts longer). |

Looking at this comparison, it’s evident that sintered stone is a well-rounded winner in many categories. It’s like getting the hardness and durability of granite/porcelain, the consistency and ease of quartz, and the elegance of marble, all in one material – without the downsides like porosity, yellowing, or heavy maintenance. As a manufacturer and supplier, I often position sintered stone to clients as the future of high-performance surfaces. It lets them offer end-users a product that checks all the boxes – beauty, strength, and peace of mind. When Victor K. (our distributor in Indonesia) switched some of his lineup from natural stone to sintered stone, he found that his customers were delighted not just by the look, but by the fact that they didn’t have to worry about the product in daily use. That’s the real advantage of sintered stone: it performs so well across the board that it removes many of the traditional compromises in material selection.

Conclusion

In conclusion, sintered stone brings a revolutionary mix of advantages to the table. It is stain resistant, durable, heat proof, and scratch resistant, addressing all the pain points we face with other materials. Sintered stone’s performance under heavy use, combined with its ease of maintenance and eco-friendly nature, make it a compelling choice for international distributors and project buyers seeking quality and reliability. It’s a surface that delivers the elegant aesthetics clients desire without the usual trade-offs. Having worked with porcelain and stone for years, I genuinely believe sintered stone offers the best of all worlds – a material you can trust to stay beautiful and strong for decades. I hope this comprehensive look at its advantages helps you make informed decisions and confidently consider sintered stone for your next project.

-

Learn about the benefits of non-porous surfaces in countertops, including stain resistance and ease of maintenance. ↩

-

Explore how sintered stone's unique properties ensure it remains stain resistant, making it ideal for kitchens and high-traffic areas. ↩

-

Discover why sintered stone is considered a 'forever' material, perfect for high-use environments with its exceptional durability. ↩

-

Learn how sintered stone's heat resistance outperforms other materials, ensuring your surfaces remain intact under high temperatures. ↩

-

Learn how sintered stone's scratch resistance compares to other materials, ensuring your countertops remain pristine over time. ↩

-

Discover how recycled materials are integrated into construction, enhancing sustainability and reducing waste in building projects. ↩