What Is Honed Porcelain Tile?

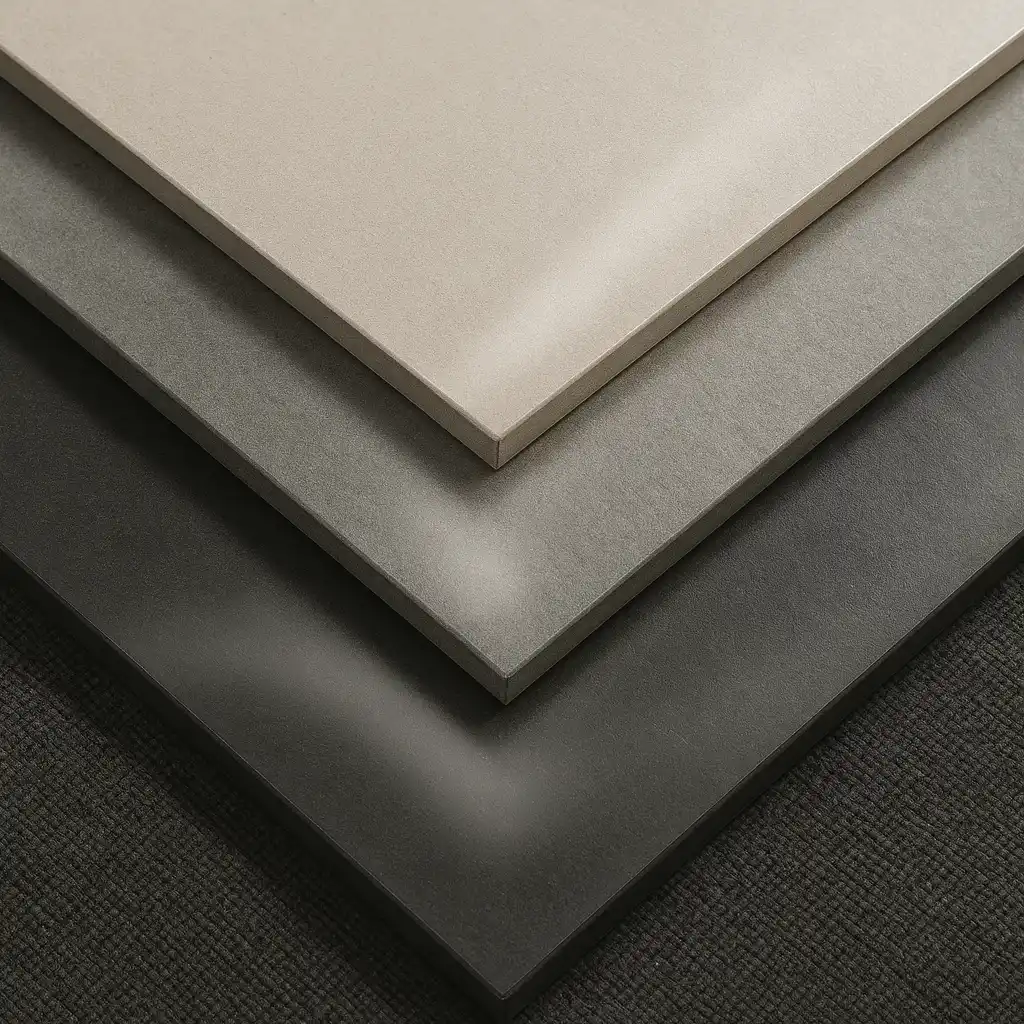

Honed porcelain tile (also called honed tile or honed surface tile) is porcelain with a smooth, flat finish and a soft, low sheen. The gloss level sits between polished and matte, usually around 25–55 on a gloss meter, so the surface reflects light gently and avoids harsh glare. This finish shows color and pattern clearly but keeps the look calm and refined. Many buyers choose it when they want elegance without mirror-like shine.

Honed porcelain uses controlled finishing to reduce gloss and create a satin effect. Core traits include soft luster, fine touch, and good everyday traction compared with glossy tiles. The visual tone feels warm and high-end, similar to stone, without the bright reflection of a polished surface. These traits make honed tiles suitable for both homes and commercial spaces.

How manufacturers achieve a honed surface (common routes):

- Special soft-gloss glaze fired on the body to create gentle sheen.

- Satin glaze for tighter gloss control and smoother hand-feel.

- Micro-relief (engraved) glaze to add fine texture and depth.

- Brush-polish after firing to subtly lower shine and mimic natural stone.

Honed vs Polished vs Matte: What’s the Difference?

Surface look and glare: Polished is high-gloss and mirror-like; glare can be strong in bright spaces. Matte is fully diffuse with no glare. Honed sits in the middle and keeps glare low even in large areas.

Slip feel and cleaning: Polished offers the slickest feel and the easiest wipe, but it shows dust and water marks fast. Matte gives the best grip, yet texture can trap dirt and need more scrubbing. Honed provides good grip and easier upkeep than heavy-texture matte, so it balances safety and maintenance.

Style signal: Polished reads bright and formal. Matte reads natural and low-key. Honed reads elegant and understated, which suits modern and luxury briefs without visual noise.

Which Is Better—Polished, Matte, or Honed Porcelain?

Choose by project goals. Pick polished when you need maximum brightness and a glamorous, reflective look. Choose matte when slip safety and a natural tone are the top priorities. Choose honed when you want a premium look with balanced slip feel and easy maintenance.

For large living areas and corridors, honed keeps the space high-end with minimal glare, even under strong light. It avoids “light pollution” that can happen with big polished surfaces. Designers often use large-format honed porcelain to set a quiet, upscale base in open plans.

Is Honed Porcelain Tile Slippery?

In dry use, honed porcelain offers better traction than polished because it does not have a mirror glaze. On wet floors, performance depends on micro-texture and slip rating. For bathrooms and other wet zones, choose honed tiles with surface texture or a higher slip coefficient. A very smooth honed tile can feel slippery when water sits on it.

Are Honed Porcelain Tiles Easy to Clean?

Yes. The surface is smooth, so routine sweeping and mopping work well. Honed hides minor water spots and dust better than glossy surfaces, yet it avoids the deep texture that traps grime on some matte tiles. Many buyers value this balance of “looks clean” and “cleans easily.”

Care tips that work for busy sites: Use a slightly damp mop for daily care, and a neutral cleaner for stubborn marks. Avoid strong acids or alkalis to protect the glaze. Regular maintenance keeps the finish even and refined.

Do Honed Porcelain Tiles Need Sealing?

Porcelain bodies are dense and low-absorption, so most honed porcelain tiles do not need sealing1. Always check the product sheet for exceptions, and seal cementitious grout if stain resistance is critical. For B2B installs, request data sheets that show water absorption and stain test results. This helps align expectations with facility cleaning protocols.

Pros & Cons at a Glance (Comparison Table)

| Factor | Honed Porcelain Tile | Polished Porcelain | Matte Porcelain |

|---|---|---|---|

| Gloss | Low sheen (approx. 25–55). Soft reflection with minimal glare. | High-gloss, mirror-like. Strong glare in bright light. | Flat, diffuse. No glare. |

| Slip Feel | Good everyday grip; choose textured honed for wet zones. | Slickest underfoot; higher slip risk when wet. | Highest grip; best for consistently wet floors. |

| Cleaning | Smooth and easy to mop; does not broadcast streaks. | Very easy to wipe but shows smudges quickly. | Hides marks but texture can trap dirt. |

| Visual Style | Elegant, understated, stone-like. | Bright, formal, glamorous. | Natural, low-key, casual. |

| Best Fit | Balanced spec where both look and function matter. | Feature walls, low-wet floors seeking luxe shine. | Wet floors, back-of-house, and high-traffic safety zones. |

Where Honed Porcelain Shines (Best Rooms & Use-Cases)

Living rooms, dining rooms, corridors. Honed sets a refined base and avoids large-area glare from strong daylight or downlights. It supports long viewing hours without eye strain and keeps the design premium. Large-format honed tiles help spaces read calm and continuous.

Bedrooms. The soft sheen and smooth touch fit a quiet, comfortable mood. Barefoot comfort feels better than a mirror-slick polish and many rough mattes. This finish supports “hotel calm” without looking dull.

Kitchens. Honed gives better slip feel than polished on floors that may see water or oil. On walls and floors it balances easy wiping with less visible splatter marks than high-gloss. This makes day-to-day cleaning simpler for busy teams.

Bathrooms and wet zones. Use honed tiles that add micro-texture or higher slip rating on floors. Smooth honed can get slippery with soap and water, while walls benefit from the spa-like, low-glare look and easy wipe-down. Match the tile’s rating to the zone’s water load.

Commercial spaces (hotels, cafés, offices, galleries). Honed projects taste and restraint, which suits public areas that need a premium tone without glare. It is common in lobbies, cafés, and showrooms where a quiet, upscale read helps sales and branding. It is also practical for cleaning and long hours of foot traffic.

Sourcing Notes for B2B Buyers of Honed Tile

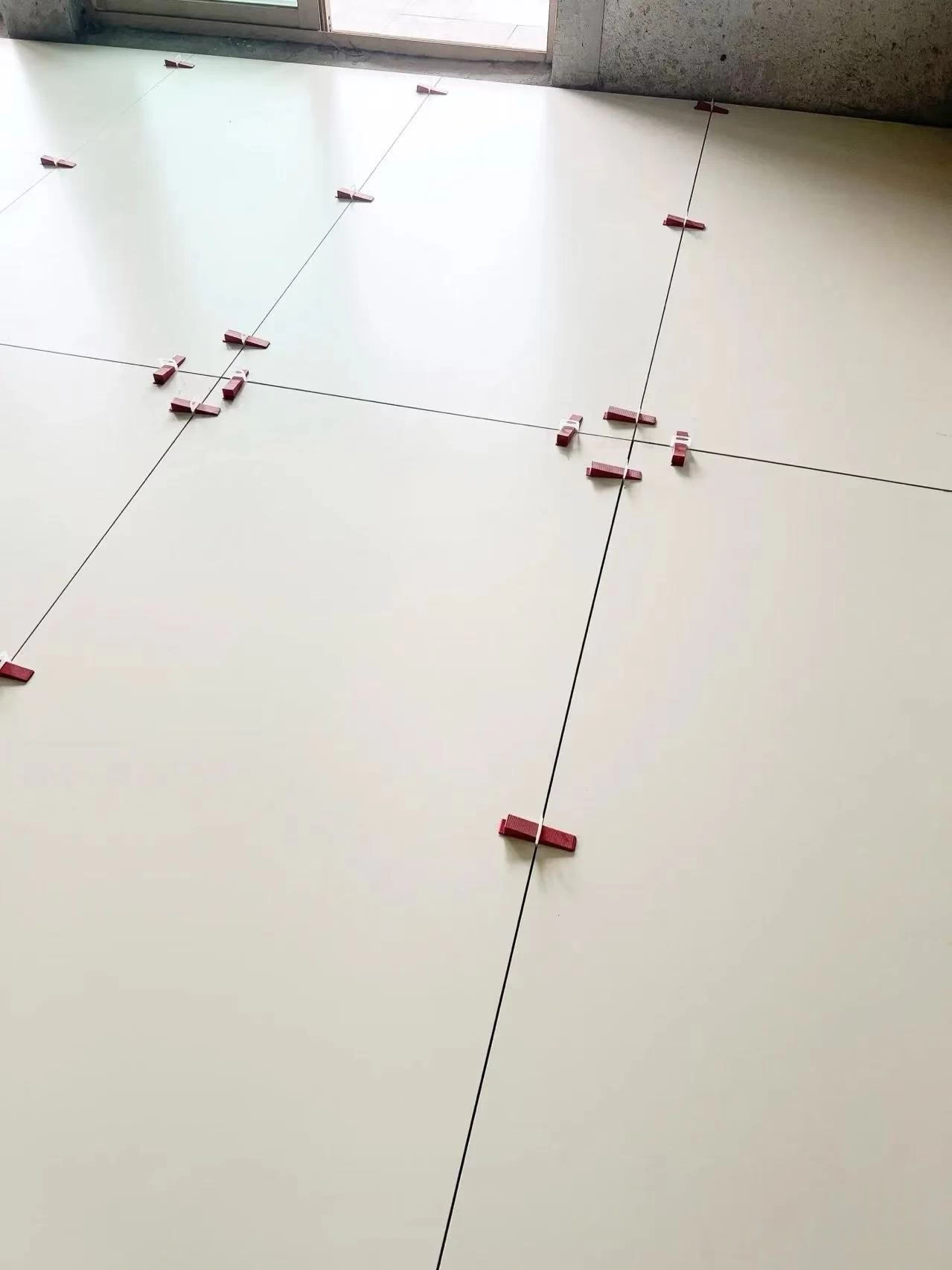

Quality control. Ask for slip ratings2 (e.g., R9–R11 for wet floors), water absorption, and stain tests on the actual batch. Inspect micro-texture uniformity across large-format pieces to avoid mixed traction in the same zone. Run a quick wet-foot test on site samples before PO confirmation.

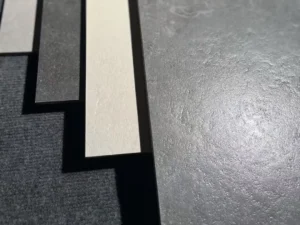

Finish verification. Confirm whether the product is a soft-gloss glaze, satin glaze, micro-relief glaze, or brush-polished surface. Each route affects feel, anti-slip, and cleanability. Reject “pseudo-honed” products that only reduce gloss but have poor oil- and water-repellence, which tends to show footprints and scale.

Documentation and certification. Request full spec sheets, slip resistance reports, and country-of-destination compliance docs. Verify certificates with the issuing body when stakes are high, since fake certificates still occur in fragmented supplier markets. Use third-party inspection to spot-check factory claims before shipment.

Logistics and delivery. Lock production slots early to hit selling seasons. Align packing plans with distributor break-bulk needs and ask for pallet maps by SKU and shade for faster intake. Add buffer days for port congestion and coordinate payment terms that reward on-time dispatch.

Communication rhythm. Set a simple update cadence: glaze batch, first piece off line, mid-run photos, pre-pack photos, and final CMs. This reduces misreads and keeps both sides accountable. Keep feedback short and visual so the factory floor can act fast.